5bc62d8fda524f52f272f615a0d276a5.ppt

- Количество слайдов: 33

0. 25 mm CMOS electronics in CMS APV 25 - readout chip for Si Tracker production wafer testing status yield experiences production QA results MGPA - Multi-Gain Pre-Amplifier chip for ECAL prototype design & performance current status November, 2003 UK CMS Collaboration Meeting 1

0. 25 mm CMOS electronics in CMS APV 25 - readout chip for Si Tracker production wafer testing status yield experiences production QA results MGPA - Multi-Gain Pre-Amplifier chip for ECAL prototype design & performance current status November, 2003 UK CMS Collaboration Meeting 1

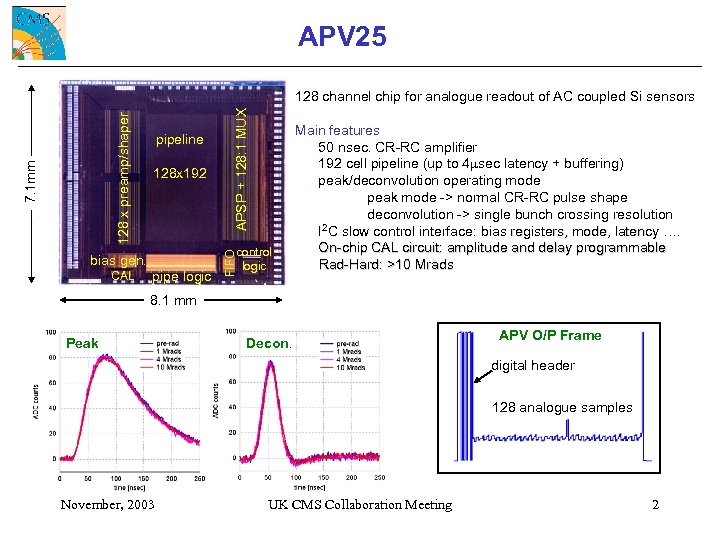

APV 25 128 x 192 bias gen. CAL pipe logic APSP + 128: 1 MUX pipeline control logic FIFO 7. 1 mm 128 x preamp/shaper 128 channel chip for analogue readout of AC coupled Si sensors Main features 50 nsec. CR-RC amplifier 192 cell pipeline (up to 4 msec latency + buffering) peak/deconvolution operating mode peak mode -> normal CR-RC pulse shape deconvolution -> single bunch crossing resolution 2 C slow control interface: bias registers, mode, latency …. I On-chip CAL circuit: amplitude and delay programmable Rad-Hard: >10 Mrads 8. 1 mm Peak Decon. APV O/P Frame digital header 128 analogue samples November, 2003 UK CMS Collaboration Meeting 2

APV 25 128 x 192 bias gen. CAL pipe logic APSP + 128: 1 MUX pipeline control logic FIFO 7. 1 mm 128 x preamp/shaper 128 channel chip for analogue readout of AC coupled Si sensors Main features 50 nsec. CR-RC amplifier 192 cell pipeline (up to 4 msec latency + buffering) peak/deconvolution operating mode peak mode -> normal CR-RC pulse shape deconvolution -> single bunch crossing resolution 2 C slow control interface: bias registers, mode, latency …. I On-chip CAL circuit: amplitude and delay programmable Rad-Hard: >10 Mrads 8. 1 mm Peak Decon. APV O/P Frame digital header 128 analogue samples November, 2003 UK CMS Collaboration Meeting 2

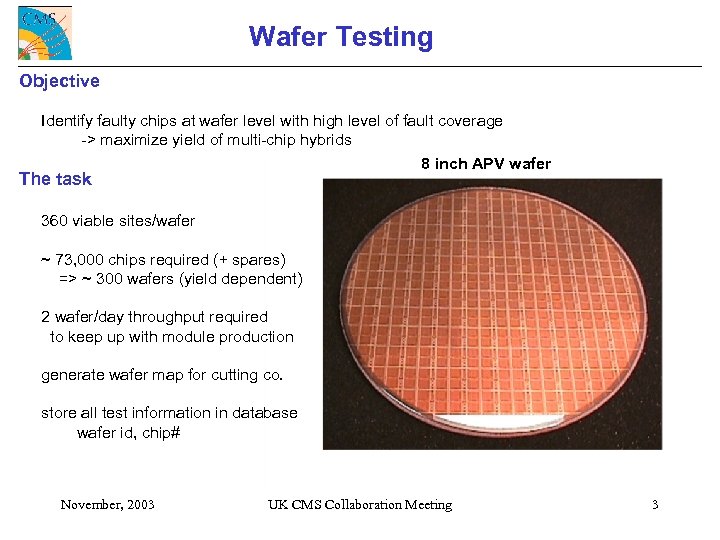

Wafer Testing Objective Identify faulty chips at wafer level with high level of fault coverage -> maximize yield of multi-chip hybrids 8 inch APV wafer The task 360 viable sites/wafer ~ 73, 000 chips required (+ spares) => ~ 300 wafers (yield dependent) 2 wafer/day throughput required to keep up with module production generate wafer map for cutting co. store all test information in database wafer id, chip# November, 2003 UK CMS Collaboration Meeting 3

Wafer Testing Objective Identify faulty chips at wafer level with high level of fault coverage -> maximize yield of multi-chip hybrids 8 inch APV wafer The task 360 viable sites/wafer ~ 73, 000 chips required (+ spares) => ~ 300 wafers (yield dependent) 2 wafer/day throughput required to keep up with module production generate wafer map for cutting co. store all test information in database wafer id, chip# November, 2003 UK CMS Collaboration Meeting 3

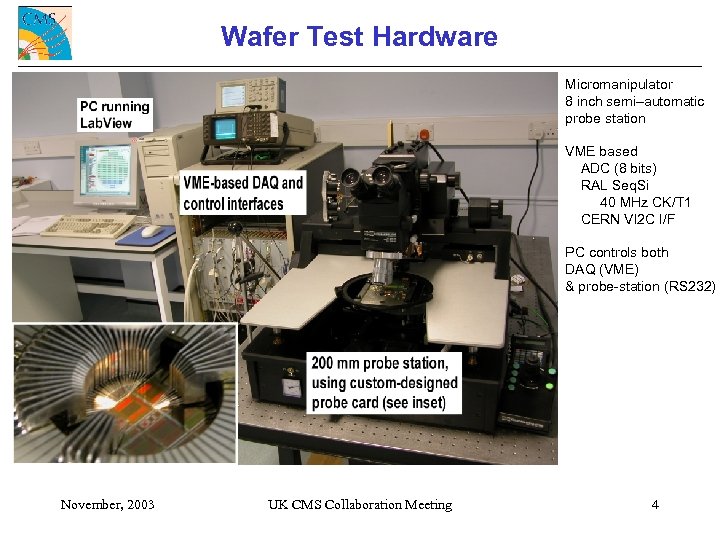

Wafer Test Hardware Micromanipulator 8 inch semi–automatic probe station VME based ADC (8 bits) RAL Seq. Si 40 MHz CK/T 1 CERN VI 2 C I/F PC controls both DAQ (VME) & probe-station (RS 232) November, 2003 UK CMS Collaboration Meeting 4

Wafer Test Hardware Micromanipulator 8 inch semi–automatic probe station VME based ADC (8 bits) RAL Seq. Si 40 MHz CK/T 1 CERN VI 2 C I/F PC controls both DAQ (VME) & probe-station (RS 232) November, 2003 UK CMS Collaboration Meeting 4

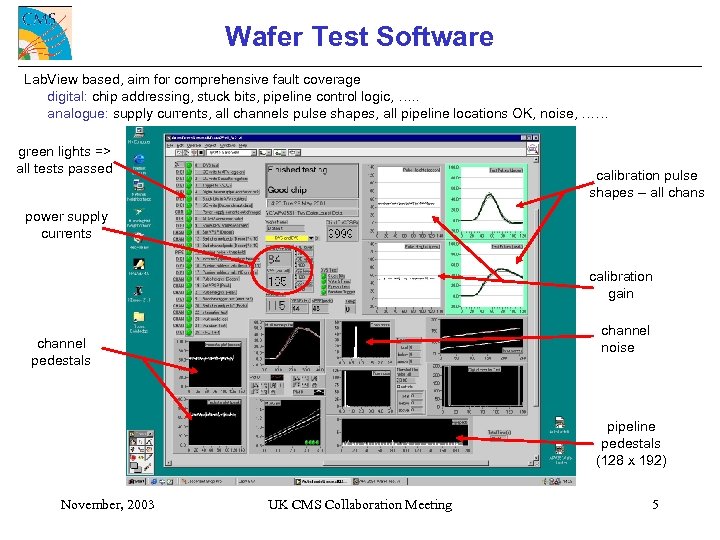

Wafer Test Software Lab. View based, aim for comprehensive fault coverage digital: chip addressing, stuck bits, pipeline control logic, …. . analogue: supply currents, all channels pulse shapes, all pipeline locations OK, noise, …… green lights => all tests passed calibration pulse shapes – all chans power supply currents calibration gain channel noise channel pedestals pipeline pedestals (128 x 192) November, 2003 UK CMS Collaboration Meeting 5

Wafer Test Software Lab. View based, aim for comprehensive fault coverage digital: chip addressing, stuck bits, pipeline control logic, …. . analogue: supply currents, all channels pulse shapes, all pipeline locations OK, noise, …… green lights => all tests passed calibration pulse shapes – all chans power supply currents calibration gain channel noise channel pedestals pipeline pedestals (128 x 192) November, 2003 UK CMS Collaboration Meeting 5

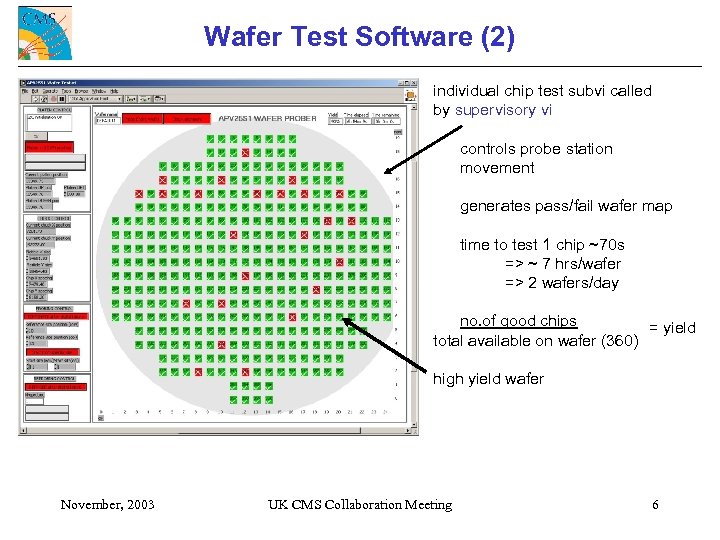

Wafer Test Software (2) individual chip test subvi called by supervisory vi controls probe station movement generates pass/fail wafer map time to test 1 chip ~70 s => ~ 7 hrs/wafer => 2 wafers/day no. of good chips = yield total available on wafer (360) high yield wafer November, 2003 UK CMS Collaboration Meeting 6

Wafer Test Software (2) individual chip test subvi called by supervisory vi controls probe station movement generates pass/fail wafer map time to test 1 chip ~70 s => ~ 7 hrs/wafer => 2 wafers/day no. of good chips = yield total available on wafer (360) high yield wafer November, 2003 UK CMS Collaboration Meeting 6

![Wafer Test – Yield Experiences date lot # wafers yield [%] 0 9 81 Wafer Test – Yield Experiences date lot # wafers yield [%] 0 9 81](https://present5.com/presentation/5bc62d8fda524f52f272f615a0d276a5/image-7.jpg) Wafer Test – Yield Experiences date lot # wafers yield [%] 0 9 81 Jan 2002 1 24 ~30 2 21 ~10 March 3 25 79 May 4 25 28 5 2002 2001 2003 Lot 1 23 42 6 25 ~0 7 23 37 Jan April 8 24 58 (long story, cut short here) problems seen as soon as production started circular failure patterns => processing problem (acknowledged by manufacturer) other HEP designs also experiencing similar problems Lot 3 2002 actions to understand unsuccessful major investigation launched February this year (following Jan deliveries) - wafers from all problem lots sent for failure analysis (FA) - modified wafer test software – try to localize failures within chip - weekly phone conference set up involving manufacturer’s FA teams on 2 sites, IC & RAL, CERN coordinating team November, 2003 UK CMS Collaboration Meeting 7

Wafer Test – Yield Experiences date lot # wafers yield [%] 0 9 81 Jan 2002 1 24 ~30 2 21 ~10 March 3 25 79 May 4 25 28 5 2002 2001 2003 Lot 1 23 42 6 25 ~0 7 23 37 Jan April 8 24 58 (long story, cut short here) problems seen as soon as production started circular failure patterns => processing problem (acknowledged by manufacturer) other HEP designs also experiencing similar problems Lot 3 2002 actions to understand unsuccessful major investigation launched February this year (following Jan deliveries) - wafers from all problem lots sent for failure analysis (FA) - modified wafer test software – try to localize failures within chip - weekly phone conference set up involving manufacturer’s FA teams on 2 sites, IC & RAL, CERN coordinating team November, 2003 UK CMS Collaboration Meeting 7

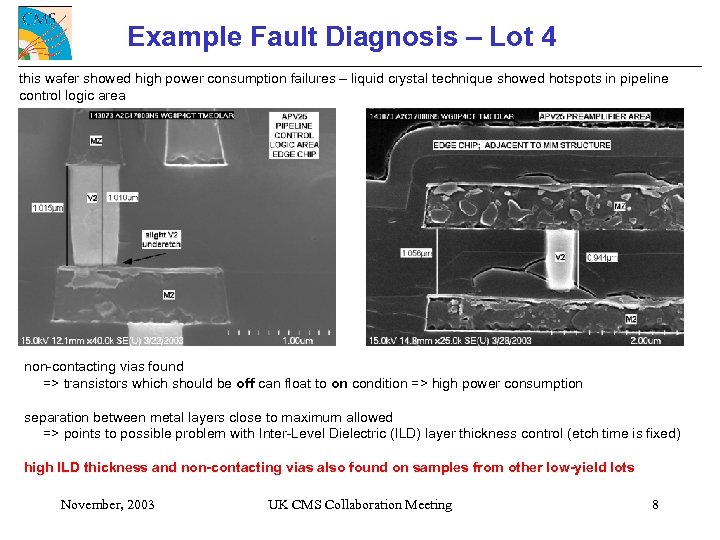

Example Fault Diagnosis – Lot 4 this wafer showed high power consumption failures – liquid crystal technique showed hotspots in pipeline control logic area non-contacting vias found => transistors which should be off can float to on condition => high power consumption separation between metal layers close to maximum allowed => points to possible problem with Inter-Level Dielectric (ILD) layer thickness control (etch time is fixed) high ILD thickness and non-contacting vias also found on samples from other low-yield lots November, 2003 UK CMS Collaboration Meeting 8

Example Fault Diagnosis – Lot 4 this wafer showed high power consumption failures – liquid crystal technique showed hotspots in pipeline control logic area non-contacting vias found => transistors which should be off can float to on condition => high power consumption separation between metal layers close to maximum allowed => points to possible problem with Inter-Level Dielectric (ILD) layer thickness control (etch time is fixed) high ILD thickness and non-contacting vias also found on samples from other low-yield lots November, 2003 UK CMS Collaboration Meeting 8

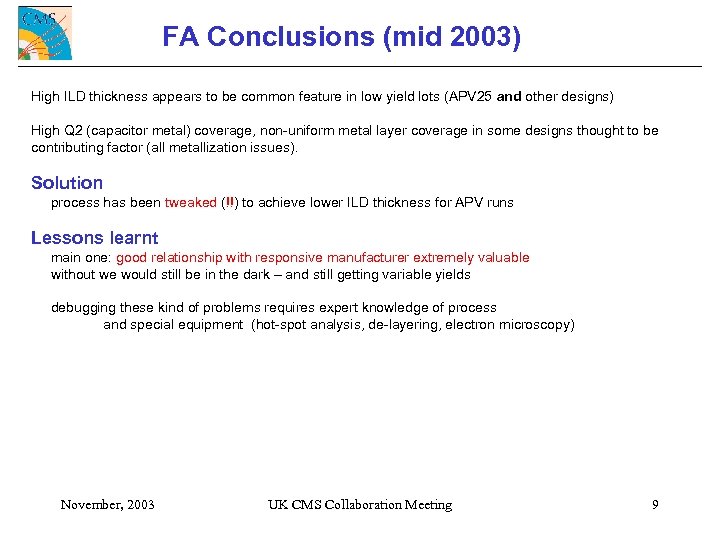

FA Conclusions (mid 2003) High ILD thickness appears to be common feature in low yield lots (APV 25 and other designs) High Q 2 (capacitor metal) coverage, non-uniform metal layer coverage in some designs thought to be contributing factor (all metallization issues). Solution process has been tweaked (!!) to achieve lower ILD thickness for APV runs Lessons learnt main one: good relationship with responsive manufacturer extremely valuable without we would still be in the dark – and still getting variable yields debugging these kind of problems requires expert knowledge of process and special equipment (hot-spot analysis, de-layering, electron microscopy) November, 2003 UK CMS Collaboration Meeting 9

FA Conclusions (mid 2003) High ILD thickness appears to be common feature in low yield lots (APV 25 and other designs) High Q 2 (capacitor metal) coverage, non-uniform metal layer coverage in some designs thought to be contributing factor (all metallization issues). Solution process has been tweaked (!!) to achieve lower ILD thickness for APV runs Lessons learnt main one: good relationship with responsive manufacturer extremely valuable without we would still be in the dark – and still getting variable yields debugging these kind of problems requires expert knowledge of process and special equipment (hot-spot analysis, de-layering, electron microscopy) November, 2003 UK CMS Collaboration Meeting 9

![Wafer Test Yields Summary – to date lot # wafers yield [%] 0 9 Wafer Test Yields Summary – to date lot # wafers yield [%] 0 9](https://present5.com/presentation/5bc62d8fda524f52f272f615a0d276a5/image-10.jpg) Wafer Test Yields Summary – to date lot # wafers yield [%] 0 9 81 engineering run Jan 1 24 ~30 2 21 ~10 1 st two production lots showed problems – manufacturer found defects in silicide layer – these wafers replaced March 3 25 79 better yield May 4 25 28 5 23 42 low yields again – major investigation launched involving manufacturer, CERN, other HEP teams with yield problems 6 25 ~0 one-off: Failure Analysis showed lots of shorted tracks 7 23 37 April 8 24 58 on-going investigations show strong evidence that problem caused by too thick dielectric between metal layers June 2002 2001 9 19 90 1 st production run with modified process July 10 22 81 Aug. 11 12 76 Sept. 12 22 79 13 25 90 14 1 91 15 24 91 16 25 90 2003 Jan Oct. experimental lot very high yield since process modified to reduce inter-level dielectric thickness looks like problem solved 184 wafers (excluding lots 1, 2 & 4 - 8) , ~ 53, 000 good chips November, 2003 UK CMS Collaboration Meeting 10

Wafer Test Yields Summary – to date lot # wafers yield [%] 0 9 81 engineering run Jan 1 24 ~30 2 21 ~10 1 st two production lots showed problems – manufacturer found defects in silicide layer – these wafers replaced March 3 25 79 better yield May 4 25 28 5 23 42 low yields again – major investigation launched involving manufacturer, CERN, other HEP teams with yield problems 6 25 ~0 one-off: Failure Analysis showed lots of shorted tracks 7 23 37 April 8 24 58 on-going investigations show strong evidence that problem caused by too thick dielectric between metal layers June 2002 2001 9 19 90 1 st production run with modified process July 10 22 81 Aug. 11 12 76 Sept. 12 22 79 13 25 90 14 1 91 15 24 91 16 25 90 2003 Jan Oct. experimental lot very high yield since process modified to reduce inter-level dielectric thickness looks like problem solved 184 wafers (excluding lots 1, 2 & 4 - 8) , ~ 53, 000 good chips November, 2003 UK CMS Collaboration Meeting 10

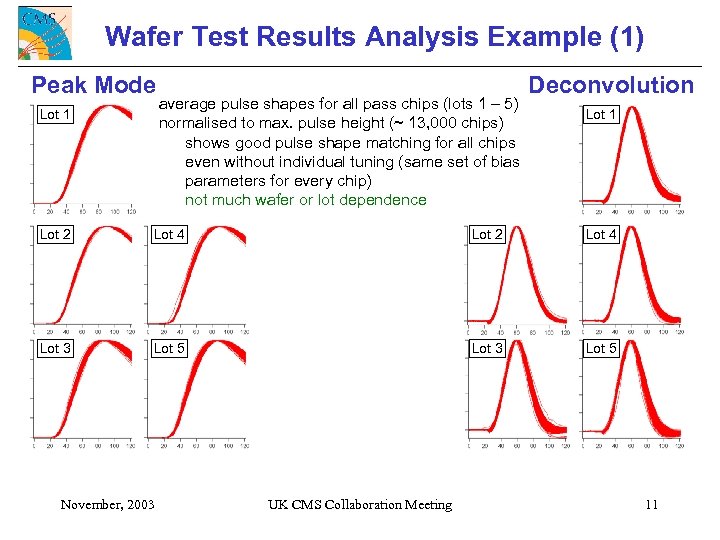

Wafer Test Results Analysis Example (1) Peak Mode Lot 1 average pulse shapes for all pass chips (lots 1 – 5) normalised to max. pulse height (~ 13, 000 chips) shows good pulse shape matching for all chips even without individual tuning (same set of bias parameters for every chip) not much wafer or lot dependence Deconvolution Lot 1 Lot 2 Lot 4 Lot 3 Lot 5 November, 2003 UK CMS Collaboration Meeting 11

Wafer Test Results Analysis Example (1) Peak Mode Lot 1 average pulse shapes for all pass chips (lots 1 – 5) normalised to max. pulse height (~ 13, 000 chips) shows good pulse shape matching for all chips even without individual tuning (same set of bias parameters for every chip) not much wafer or lot dependence Deconvolution Lot 1 Lot 2 Lot 4 Lot 3 Lot 5 November, 2003 UK CMS Collaboration Meeting 11

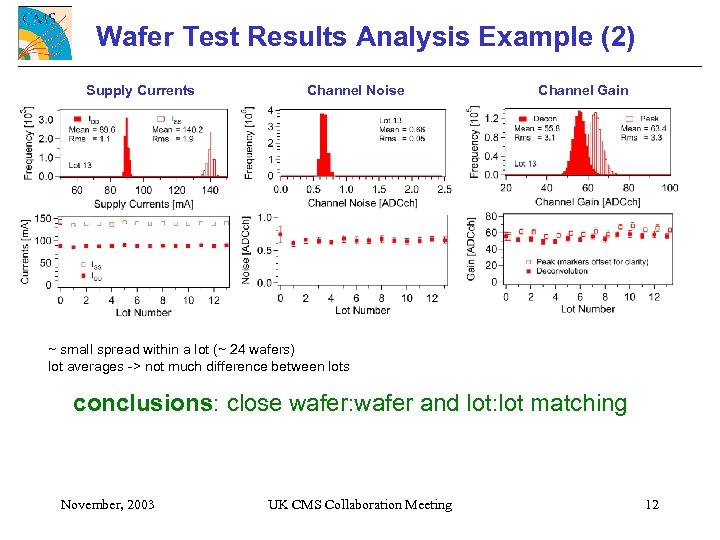

Wafer Test Results Analysis Example (2) Supply Currents Channel Noise Channel Gain ~ small spread within a lot (~ 24 wafers) lot averages -> not much difference between lots conclusions: close wafer: wafer and lot: lot matching November, 2003 UK CMS Collaboration Meeting 12

Wafer Test Results Analysis Example (2) Supply Currents Channel Noise Channel Gain ~ small spread within a lot (~ 24 wafers) lot averages -> not much difference between lots conclusions: close wafer: wafer and lot: lot matching November, 2003 UK CMS Collaboration Meeting 12

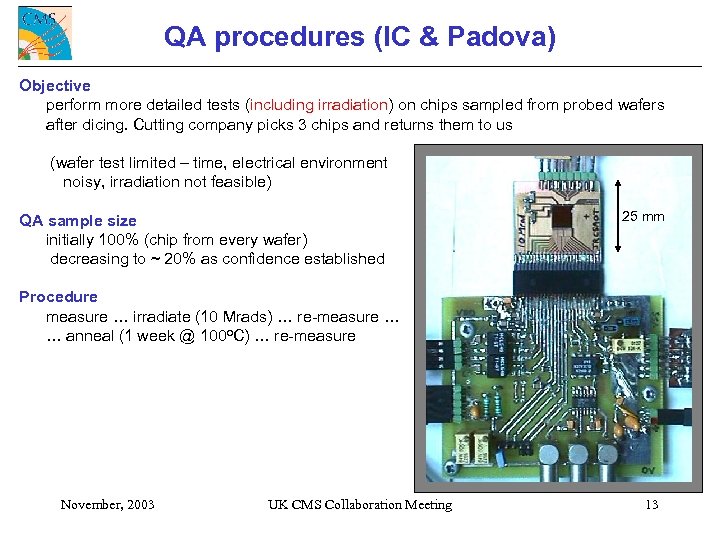

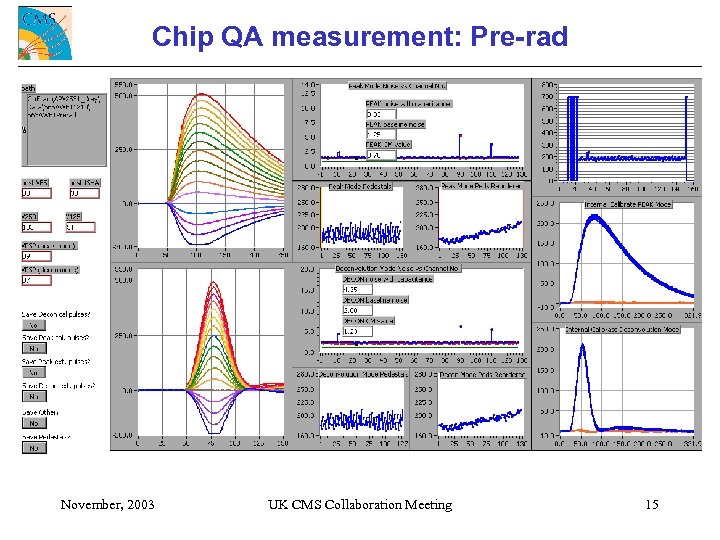

QA procedures (IC & Padova) Objective perform more detailed tests (including irradiation) on chips sampled from probed wafers after dicing. Cutting company picks 3 chips and returns them to us (wafer test limited – time, electrical environment noisy, irradiation not feasible) QA sample size initially 100% (chip from every wafer) decreasing to ~ 20% as confidence established 25 mm Procedure measure … irradiate (10 Mrads) … re-measure … … anneal (1 week @ 100 o. C) … re-measure November, 2003 UK CMS Collaboration Meeting 13

QA procedures (IC & Padova) Objective perform more detailed tests (including irradiation) on chips sampled from probed wafers after dicing. Cutting company picks 3 chips and returns them to us (wafer test limited – time, electrical environment noisy, irradiation not feasible) QA sample size initially 100% (chip from every wafer) decreasing to ~ 20% as confidence established 25 mm Procedure measure … irradiate (10 Mrads) … re-measure … … anneal (1 week @ 100 o. C) … re-measure November, 2003 UK CMS Collaboration Meeting 13

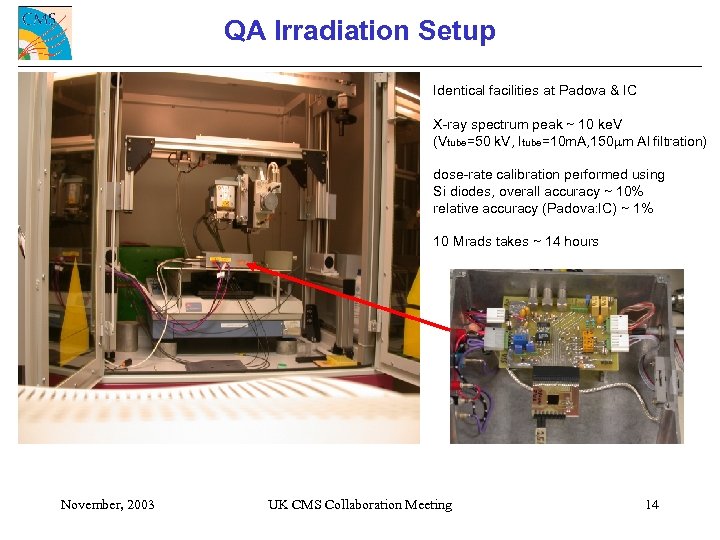

QA Irradiation Setup Identical facilities at Padova & IC X-ray spectrum peak ~ 10 ke. V (Vtube=50 k. V, Itube=10 m. A, 150 mm Al filtration) dose-rate calibration performed using Si diodes, overall accuracy ~ 10% relative accuracy (Padova: IC) ~ 1% 10 Mrads takes ~ 14 hours November, 2003 UK CMS Collaboration Meeting 14

QA Irradiation Setup Identical facilities at Padova & IC X-ray spectrum peak ~ 10 ke. V (Vtube=50 k. V, Itube=10 m. A, 150 mm Al filtration) dose-rate calibration performed using Si diodes, overall accuracy ~ 10% relative accuracy (Padova: IC) ~ 1% 10 Mrads takes ~ 14 hours November, 2003 UK CMS Collaboration Meeting 14

Chip QA measurement: Pre-rad November, 2003 UK CMS Collaboration Meeting 15

Chip QA measurement: Pre-rad November, 2003 UK CMS Collaboration Meeting 15

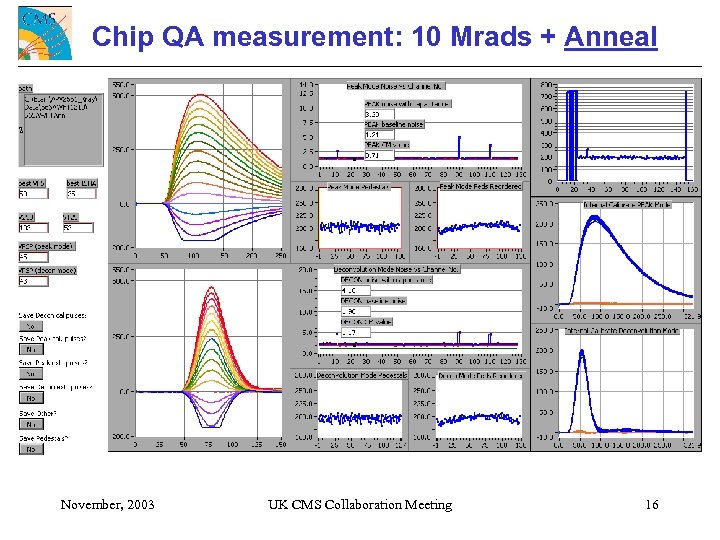

Chip QA measurement: 10 Mrads + Anneal November, 2003 UK CMS Collaboration Meeting 16

Chip QA measurement: 10 Mrads + Anneal November, 2003 UK CMS Collaboration Meeting 16

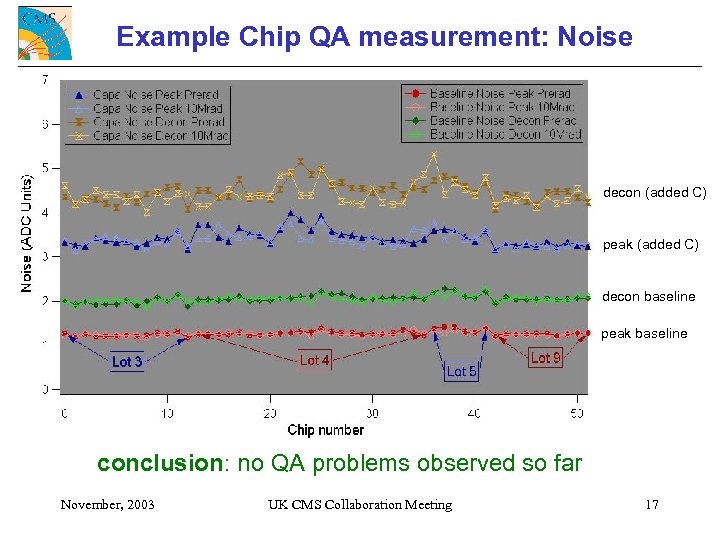

Example Chip QA measurement: Noise decon (added C) peak (added C) decon baseline peak baseline conclusion: no QA problems observed so far November, 2003 UK CMS Collaboration Meeting 17

Example Chip QA measurement: Noise decon (added C) peak (added C) decon baseline peak baseline conclusion: no QA problems observed so far November, 2003 UK CMS Collaboration Meeting 17

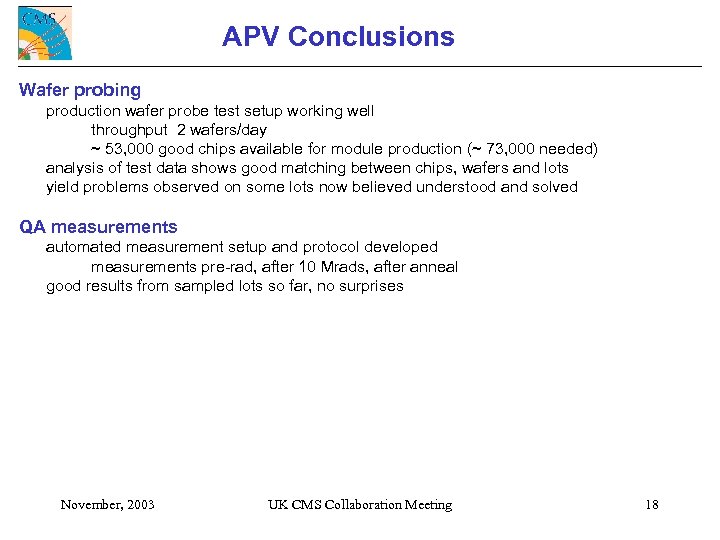

APV Conclusions Wafer probing production wafer probe test setup working well throughput 2 wafers/day ~ 53, 000 good chips available for module production (~ 73, 000 needed) analysis of test data shows good matching between chips, wafers and lots yield problems observed on some lots now believed understood and solved QA measurements automated measurement setup and protocol developed measurements pre-rad, after 10 Mrads, after anneal good results from sampled lots so far, no surprises November, 2003 UK CMS Collaboration Meeting 18

APV Conclusions Wafer probing production wafer probe test setup working well throughput 2 wafers/day ~ 53, 000 good chips available for module production (~ 73, 000 needed) analysis of test data shows good matching between chips, wafers and lots yield problems observed on some lots now believed understood and solved QA measurements automated measurement setup and protocol developed measurements pre-rad, after 10 Mrads, after anneal good results from sampled lots so far, no surprises November, 2003 UK CMS Collaboration Meeting 18

The MGPA ECAL readout chip MGPA for CMS New 0. 25 mm VFE chip for ECAL Multi–Gain Pre-Amplifier - 0. 25 mm CMOS chip for CMS ECAL Prototype results as presented at recent LECC conference Minor modifications to prototype -> new version just submitted for engineering run 9 th Workshop on Electronics for LHC Experiments, Amsterdam, 2003 November, 2003 UK CMS Collaboration Meeting 19

The MGPA ECAL readout chip MGPA for CMS New 0. 25 mm VFE chip for ECAL Multi–Gain Pre-Amplifier - 0. 25 mm CMOS chip for CMS ECAL Prototype results as presented at recent LECC conference Minor modifications to prototype -> new version just submitted for engineering run 9 th Workshop on Electronics for LHC Experiments, Amsterdam, 2003 November, 2003 UK CMS Collaboration Meeting 19

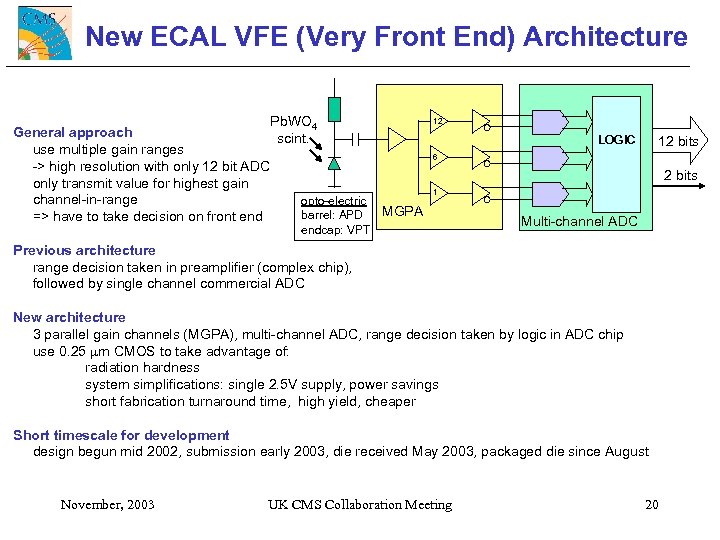

New ECAL VFE (Very Front End) Architecture Pb. WO 4 General approach scint. use multiple gain ranges -> high resolution with only 12 bit ADC only transmit value for highest gain channel-in-range opto-electric barrel: APD => have to take decision on front end 12 LOGIC 12 bits 6 2 bits 1 MGPA endcap: VPT Multi-channel ADC Previous architecture range decision taken in preamplifier (complex chip), followed by single channel commercial ADC New architecture 3 parallel gain channels (MGPA), multi-channel ADC, range decision taken by logic in ADC chip use 0. 25 mm CMOS to take advantage of: radiation hardness system simplifications: single 2. 5 V supply, power savings short fabrication turnaround time, high yield, cheaper Short timescale for development design begun mid 2002, submission early 2003, die received May 2003, packaged die since August November, 2003 UK CMS Collaboration Meeting 20

New ECAL VFE (Very Front End) Architecture Pb. WO 4 General approach scint. use multiple gain ranges -> high resolution with only 12 bit ADC only transmit value for highest gain channel-in-range opto-electric barrel: APD => have to take decision on front end 12 LOGIC 12 bits 6 2 bits 1 MGPA endcap: VPT Multi-channel ADC Previous architecture range decision taken in preamplifier (complex chip), followed by single channel commercial ADC New architecture 3 parallel gain channels (MGPA), multi-channel ADC, range decision taken by logic in ADC chip use 0. 25 mm CMOS to take advantage of: radiation hardness system simplifications: single 2. 5 V supply, power savings short fabrication turnaround time, high yield, cheaper Short timescale for development design begun mid 2002, submission early 2003, die received May 2003, packaged die since August November, 2003 UK CMS Collaboration Meeting 20

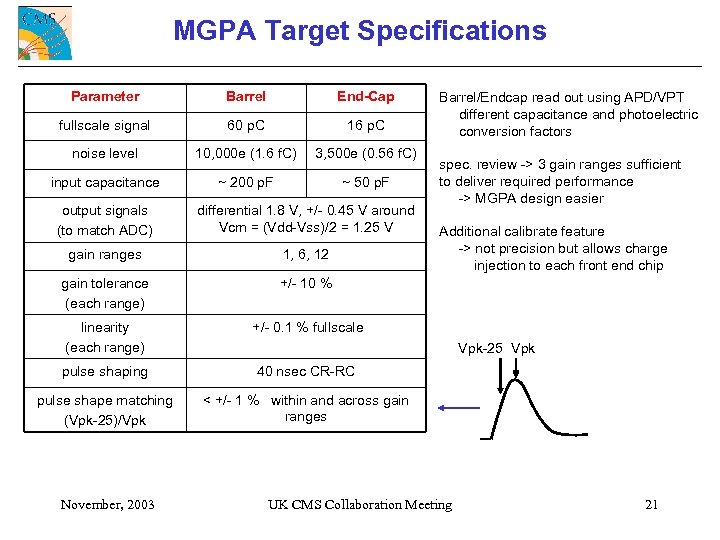

MGPA Target Specifications Parameter Barrel End-Cap fullscale signal 60 p. C 16 p. C noise level 10, 000 e (1. 6 f. C) 3, 500 e (0. 56 f. C) input capacitance ~ 200 p. F ~ 50 p. F output signals (to match ADC) differential 1. 8 V, +/- 0. 45 V around Vcm = (Vdd-Vss)/2 = 1. 25 V gain ranges 1, 6, 12 gain tolerance (each range) +/- 0. 1 % fullscale pulse shaping 40 nsec CR-RC pulse shape matching (Vpk-25)/Vpk spec. review -> 3 gain ranges sufficient to deliver required performance -> MGPA design easier +/- 10 % linearity (each range) Barrel/Endcap read out using APD/VPT different capacitance and photoelectric conversion factors < +/- 1 % within and across gain ranges November, 2003 Additional calibrate feature -> not precision but allows charge injection to each front end chip Vpk-25 Vpk UK CMS Collaboration Meeting 21

MGPA Target Specifications Parameter Barrel End-Cap fullscale signal 60 p. C 16 p. C noise level 10, 000 e (1. 6 f. C) 3, 500 e (0. 56 f. C) input capacitance ~ 200 p. F ~ 50 p. F output signals (to match ADC) differential 1. 8 V, +/- 0. 45 V around Vcm = (Vdd-Vss)/2 = 1. 25 V gain ranges 1, 6, 12 gain tolerance (each range) +/- 0. 1 % fullscale pulse shaping 40 nsec CR-RC pulse shape matching (Vpk-25)/Vpk spec. review -> 3 gain ranges sufficient to deliver required performance -> MGPA design easier +/- 10 % linearity (each range) Barrel/Endcap read out using APD/VPT different capacitance and photoelectric conversion factors < +/- 1 % within and across gain ranges November, 2003 Additional calibrate feature -> not precision but allows charge injection to each front end chip Vpk-25 Vpk UK CMS Collaboration Meeting 21

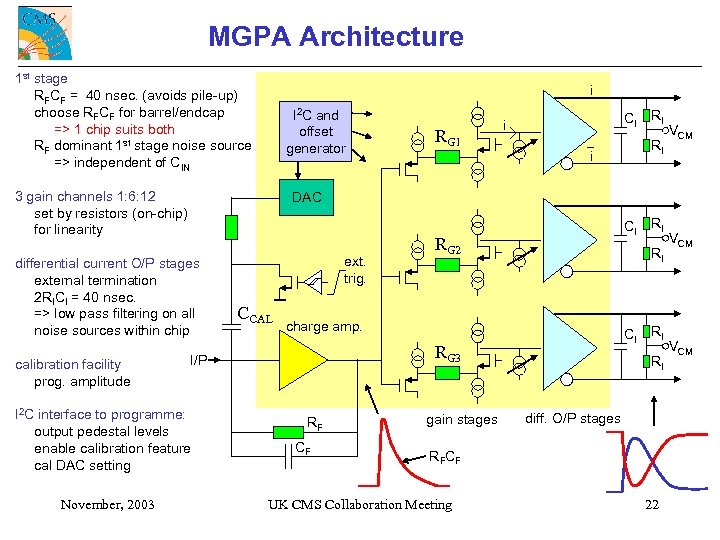

MGPA Architecture 1 st stage RFCF = 40 nsec. (avoids pile-up) choose RFCF for barrel/endcap => 1 chip suits both RF dominant 1 st stage noise source => independent of CIN i I 2 C and offset generator 3 gain channels 1: 6: 12 set by resistors (on-chip) for linearity ext. trig. CCAL RI CI RI RG 2 RI charge amp. CI RI RG 3 I/P I 2 C interface to programme: output pedestal levels enable calibration feature cal DAC setting November, 2003 i VCM DAC differential current O/P stages external termination 2 RICI = 40 nsec. => low pass filtering on all noise sources within chip calibration facility prog. amplitude RG 1 CI RI i RF CF gain stages RI diff. O/P stages RFCF UK CMS Collaboration Meeting 22 VCM

MGPA Architecture 1 st stage RFCF = 40 nsec. (avoids pile-up) choose RFCF for barrel/endcap => 1 chip suits both RF dominant 1 st stage noise source => independent of CIN i I 2 C and offset generator 3 gain channels 1: 6: 12 set by resistors (on-chip) for linearity ext. trig. CCAL RI CI RI RG 2 RI charge amp. CI RI RG 3 I/P I 2 C interface to programme: output pedestal levels enable calibration feature cal DAC setting November, 2003 i VCM DAC differential current O/P stages external termination 2 RICI = 40 nsec. => low pass filtering on all noise sources within chip calibration facility prog. amplitude RG 1 CI RI i RF CF gain stages RI diff. O/P stages RFCF UK CMS Collaboration Meeting 22 VCM

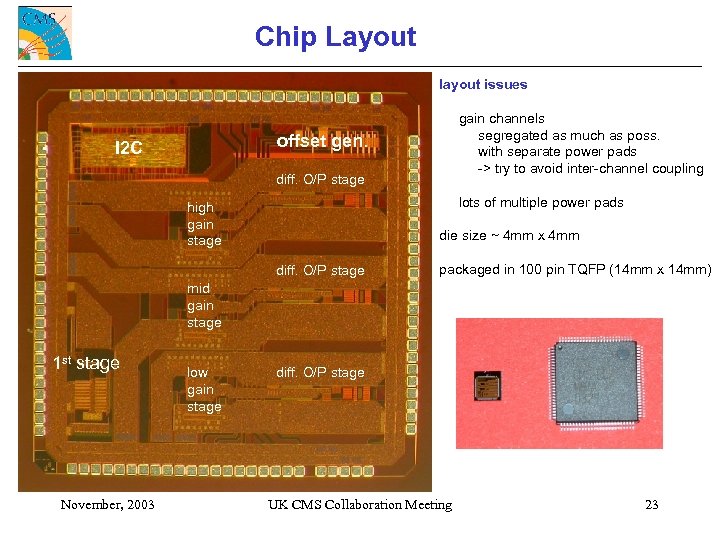

Chip Layout layout issues gain channels segregated as much as poss. with separate power pads -> try to avoid inter-channel coupling offset gen. I 2 C diff. O/P stage lots of multiple power pads high gain stage die size ~ 4 mm x 4 mm diff. O/P stage packaged in 100 pin TQFP (14 mm x 14 mm) mid gain stage 1 st stage November, 2003 low gain stage diff. O/P stage UK CMS Collaboration Meeting 23

Chip Layout layout issues gain channels segregated as much as poss. with separate power pads -> try to avoid inter-channel coupling offset gen. I 2 C diff. O/P stage lots of multiple power pads high gain stage die size ~ 4 mm x 4 mm diff. O/P stage packaged in 100 pin TQFP (14 mm x 14 mm) mid gain stage 1 st stage November, 2003 low gain stage diff. O/P stage UK CMS Collaboration Meeting 23

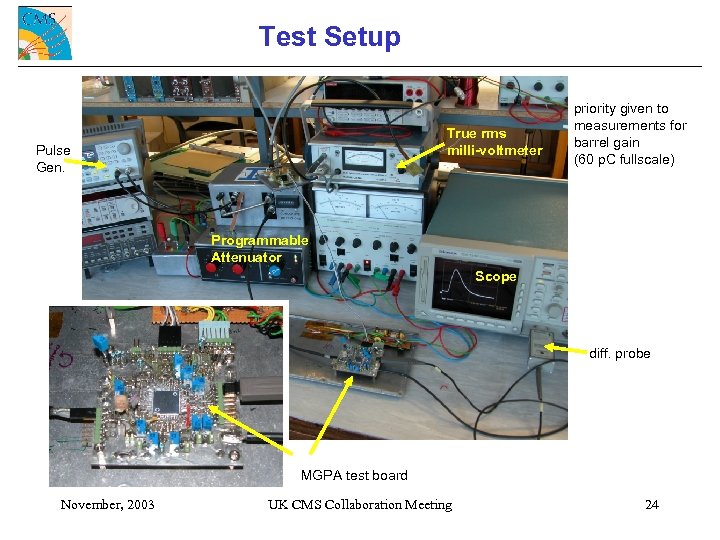

Test Setup True rms milli-voltmeter Pulse Gen. priority given to measurements for barrel gain (60 p. C fullscale) Programmable Attenuator Scope diff. probe MGPA test board November, 2003 UK CMS Collaboration Meeting 24

Test Setup True rms milli-voltmeter Pulse Gen. priority given to measurements for barrel gain (60 p. C fullscale) Programmable Attenuator Scope diff. probe MGPA test board November, 2003 UK CMS Collaboration Meeting 24

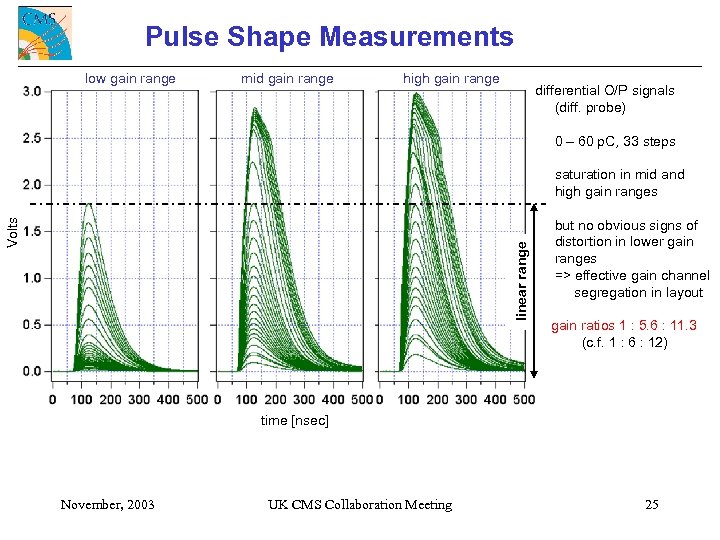

Pulse Shape Measurements low gain range mid gain range high gain range differential O/P signals (diff. probe) 0 – 60 p. C, 33 steps linear range Volts saturation in mid and high gain ranges but no obvious signs of distortion in lower gain ranges => effective gain channel segregation in layout gain ratios 1 : 5. 6 : 11. 3 (c. f. 1 : 6 : 12) time [nsec] November, 2003 UK CMS Collaboration Meeting 25

Pulse Shape Measurements low gain range mid gain range high gain range differential O/P signals (diff. probe) 0 – 60 p. C, 33 steps linear range Volts saturation in mid and high gain ranges but no obvious signs of distortion in lower gain ranges => effective gain channel segregation in layout gain ratios 1 : 5. 6 : 11. 3 (c. f. 1 : 6 : 12) time [nsec] November, 2003 UK CMS Collaboration Meeting 25

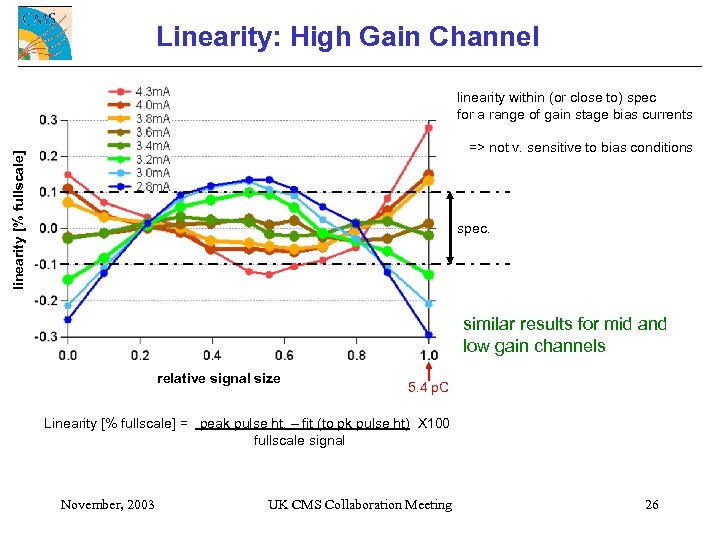

Linearity: High Gain Channel linearity within (or close to) spec for a range of gain stage bias currents linearity [% fullscale] => not v. sensitive to bias conditions spec. similar results for mid and low gain channels relative signal size 5. 4 p. C Linearity [% fullscale] = peak pulse ht. – fit (to pk pulse ht) X 100 fullscale signal November, 2003 UK CMS Collaboration Meeting 26

Linearity: High Gain Channel linearity within (or close to) spec for a range of gain stage bias currents linearity [% fullscale] => not v. sensitive to bias conditions spec. similar results for mid and low gain channels relative signal size 5. 4 p. C Linearity [% fullscale] = peak pulse ht. – fit (to pk pulse ht) X 100 fullscale signal November, 2003 UK CMS Collaboration Meeting 26

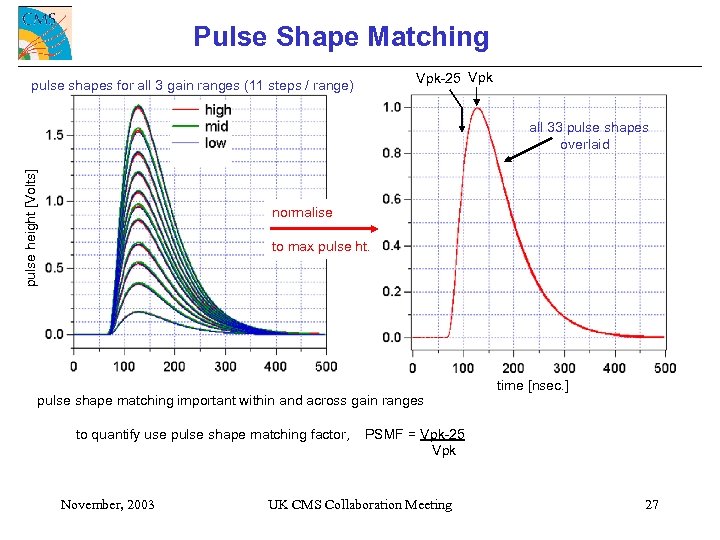

Pulse Shape Matching Vpk-25 Vpk pulse shapes for all 3 gain ranges (11 steps / range) pulse height [Volts] all 33 pulse shapes overlaid normalise to max pulse ht. pulse shape matching important within and across gain ranges to quantify use pulse shape matching factor, November, 2003 time [nsec. ] PSMF = Vpk-25 Vpk UK CMS Collaboration Meeting 27

Pulse Shape Matching Vpk-25 Vpk pulse shapes for all 3 gain ranges (11 steps / range) pulse height [Volts] all 33 pulse shapes overlaid normalise to max pulse ht. pulse shape matching important within and across gain ranges to quantify use pulse shape matching factor, November, 2003 time [nsec. ] PSMF = Vpk-25 Vpk UK CMS Collaboration Meeting 27

![pulse shape matching [%] Pulse Shape Matching spec. pulse shape matching close to spec. pulse shape matching [%] Pulse Shape Matching spec. pulse shape matching close to spec.](https://present5.com/presentation/5bc62d8fda524f52f272f615a0d276a5/image-28.jpg) pulse shape matching [%] Pulse Shape Matching spec. pulse shape matching close to spec. (+/- 1%) relative signal size [1=fullscale] Pulse shape matching [%] = (PSMF – Average PSMF) x 100 Average PSMF (Average PSMF = average over all pulse shapes and all 3 gain ranges) November, 2003 UK CMS Collaboration Meeting 28

pulse shape matching [%] Pulse Shape Matching spec. pulse shape matching close to spec. (+/- 1%) relative signal size [1=fullscale] Pulse shape matching [%] = (PSMF – Average PSMF) x 100 Average PSMF (Average PSMF = average over all pulse shapes and all 3 gain ranges) November, 2003 UK CMS Collaboration Meeting 28

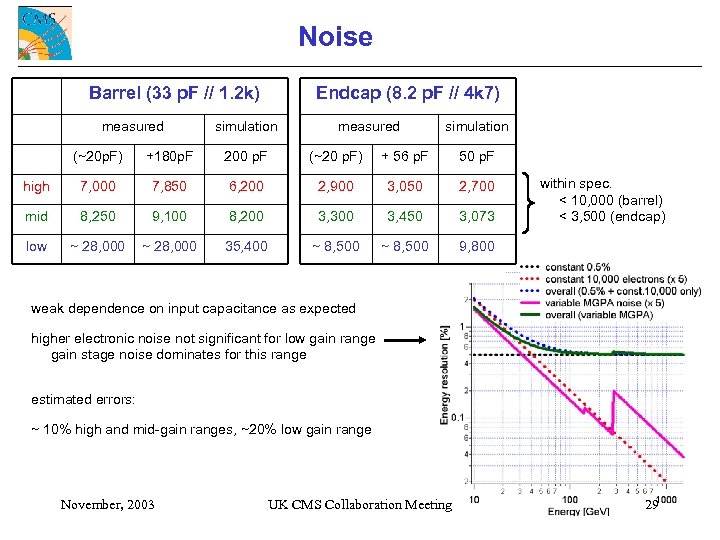

Noise Barrel (33 p. F // 1. 2 k) measured Endcap (8. 2 p. F // 4 k 7) simulation measured simulation (~20 p. F) +180 p. F 200 p. F (~20 p. F) + 56 p. F 50 p. F high 7, 000 7, 850 6, 200 2, 900 3, 050 2, 700 mid 8, 250 9, 100 8, 200 3, 300 3, 450 3, 073 low ~ 28, 000 35, 400 ~ 8, 500 9, 800 within spec. < 10, 000 (barrel) < 3, 500 (endcap) weak dependence on input capacitance as expected higher electronic noise not significant for low gain range gain stage noise dominates for this range estimated errors: ~ 10% high and mid-gain ranges, ~20% low gain range November, 2003 UK CMS Collaboration Meeting 29

Noise Barrel (33 p. F // 1. 2 k) measured Endcap (8. 2 p. F // 4 k 7) simulation measured simulation (~20 p. F) +180 p. F 200 p. F (~20 p. F) + 56 p. F 50 p. F high 7, 000 7, 850 6, 200 2, 900 3, 050 2, 700 mid 8, 250 9, 100 8, 200 3, 300 3, 450 3, 073 low ~ 28, 000 35, 400 ~ 8, 500 9, 800 within spec. < 10, 000 (barrel) < 3, 500 (endcap) weak dependence on input capacitance as expected higher electronic noise not significant for low gain range gain stage noise dominates for this range estimated errors: ~ 10% high and mid-gain ranges, ~20% low gain range November, 2003 UK CMS Collaboration Meeting 29

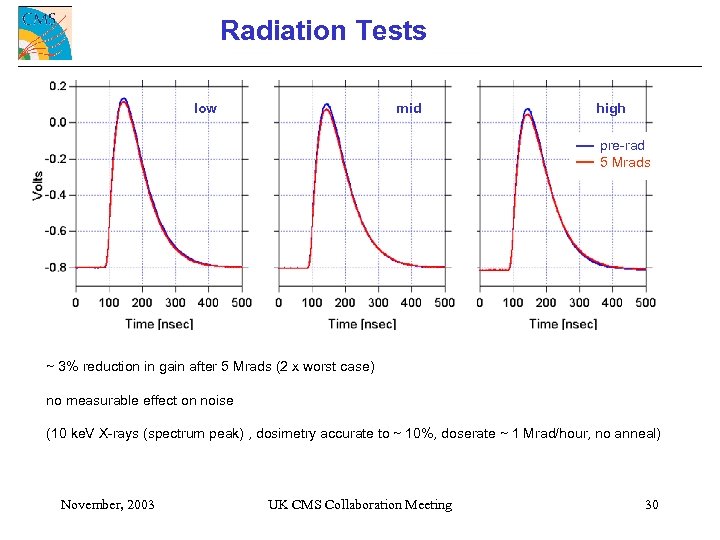

Radiation Tests low mid high pre-rad 5 Mrads ~ 3% reduction in gain after 5 Mrads (2 x worst case) no measurable effect on noise (10 ke. V X-rays (spectrum peak) , dosimetry accurate to ~ 10%, doserate ~ 1 Mrad/hour, no anneal) November, 2003 UK CMS Collaboration Meeting 30

Radiation Tests low mid high pre-rad 5 Mrads ~ 3% reduction in gain after 5 Mrads (2 x worst case) no measurable effect on noise (10 ke. V X-rays (spectrum peak) , dosimetry accurate to ~ 10%, doserate ~ 1 Mrad/hour, no anneal) November, 2003 UK CMS Collaboration Meeting 30

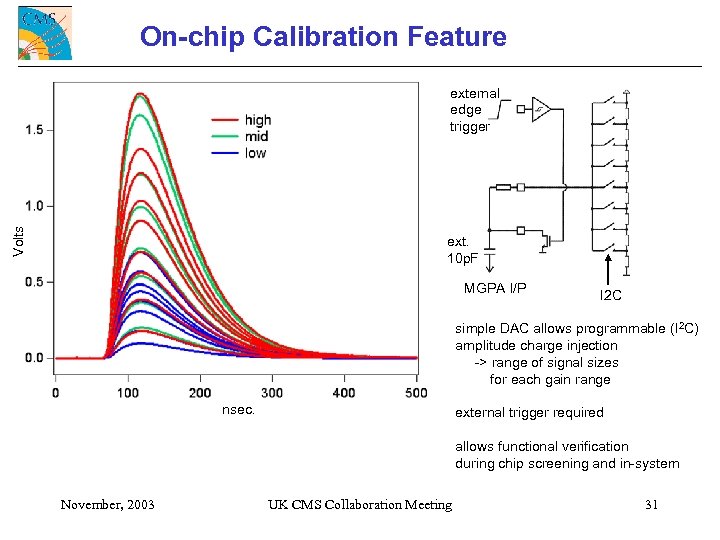

On-chip Calibration Feature Volts external edge trigger ext. 10 p. F MGPA I/P I 2 C simple DAC allows programmable (I 2 C) amplitude charge injection -> range of signal sizes for each gain range nsec. external trigger required allows functional verification during chip screening and in-system November, 2003 UK CMS Collaboration Meeting 31

On-chip Calibration Feature Volts external edge trigger ext. 10 p. F MGPA I/P I 2 C simple DAC allows programmable (I 2 C) amplitude charge injection -> range of signal sizes for each gain range nsec. external trigger required allows functional verification during chip screening and in-system November, 2003 UK CMS Collaboration Meeting 31

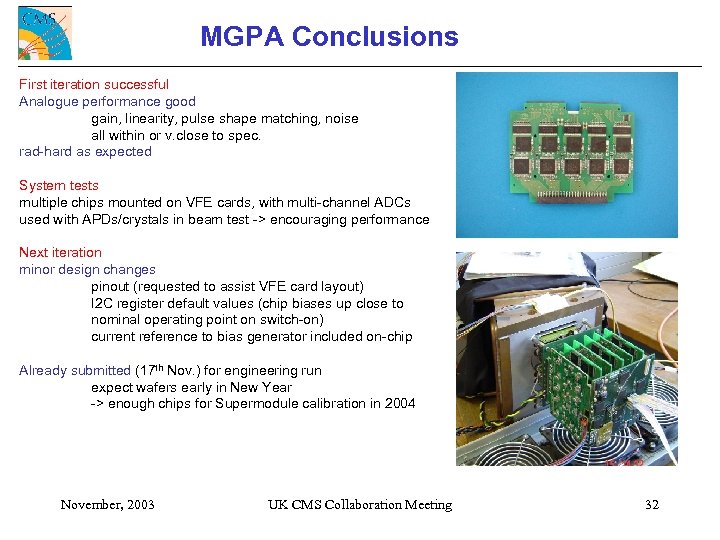

MGPA Conclusions First iteration successful Analogue performance good gain, linearity, pulse shape matching, noise all within or v. close to spec. rad-hard as expected System tests multiple chips mounted on VFE cards, with multi-channel ADCs used with APDs/crystals in beam test -> encouraging performance Next iteration minor design changes pinout (requested to assist VFE card layout) I 2 C register default values (chip biases up close to nominal operating point on switch-on) current reference to bias generator included on-chip Already submitted (17 th Nov. ) for engineering run expect wafers early in New Year -> enough chips for Supermodule calibration in 2004 November, 2003 UK CMS Collaboration Meeting 32

MGPA Conclusions First iteration successful Analogue performance good gain, linearity, pulse shape matching, noise all within or v. close to spec. rad-hard as expected System tests multiple chips mounted on VFE cards, with multi-channel ADCs used with APDs/crystals in beam test -> encouraging performance Next iteration minor design changes pinout (requested to assist VFE card layout) I 2 C register default values (chip biases up close to nominal operating point on switch-on) current reference to bias generator included on-chip Already submitted (17 th Nov. ) for engineering run expect wafers early in New Year -> enough chips for Supermodule calibration in 2004 November, 2003 UK CMS Collaboration Meeting 32

Deep Sub-Micron Future* 0. 25 mm CMOS turned up just in time (~1998) – where would we be without it? in CMS everything (I think) from HCAL in now 0. 25 mm - Pixel, Tracker, ECAL readout and control ASICs 0. 25 mm technology will not be around forever (maybe until 2007? ) 0. 13 mm next logical step (have to follow industry – skip 0. 18 mm) need special relationship with (and goodwill of) technology supplier prototypes -> production NOT a smooth ride (e. g. APV yield experiences) understanding yield issues requires close collaboration with foundry HEP projects need relatively few wafers c. f. foundry capacity 0. 13 mm offers possible improvements in: power reduction: most of tracker material budget electronics related (power cabling, cooling) higher speed and circuit density, more rad-hard, …. also challenges -> R&D required circuit techniques to cope with reduced supply headroom (1. 3 V) radiation effects (ionizing and SEE) generating and characterising digital circuit libraries (and analogue? ) modelling more complicated (more metal layers -> complex parasitic couplings) undisputable statement: LHC (and future HEP) experiments not possible without ASICs *see Sandro Marchioro’s talk at LECC’ 03 LHC electronics workshop November, 2003 UK CMS Collaboration Meeting 33

Deep Sub-Micron Future* 0. 25 mm CMOS turned up just in time (~1998) – where would we be without it? in CMS everything (I think) from HCAL in now 0. 25 mm - Pixel, Tracker, ECAL readout and control ASICs 0. 25 mm technology will not be around forever (maybe until 2007? ) 0. 13 mm next logical step (have to follow industry – skip 0. 18 mm) need special relationship with (and goodwill of) technology supplier prototypes -> production NOT a smooth ride (e. g. APV yield experiences) understanding yield issues requires close collaboration with foundry HEP projects need relatively few wafers c. f. foundry capacity 0. 13 mm offers possible improvements in: power reduction: most of tracker material budget electronics related (power cabling, cooling) higher speed and circuit density, more rad-hard, …. also challenges -> R&D required circuit techniques to cope with reduced supply headroom (1. 3 V) radiation effects (ionizing and SEE) generating and characterising digital circuit libraries (and analogue? ) modelling more complicated (more metal layers -> complex parasitic couplings) undisputable statement: LHC (and future HEP) experiments not possible without ASICs *see Sandro Marchioro’s talk at LECC’ 03 LHC electronics workshop November, 2003 UK CMS Collaboration Meeting 33