4b72035db5cfac1b74771e2285b2783c.ppt

- Количество слайдов: 19

목차 v 4. 5 Solid Fast-Ion Conductors v 4. 5. 1 Cubic stabilized zirconia (CSZ) v 4. 5. 2 The β-alumina v 4. 6 Humidity and Gas Sensors v 4. 6. 1 humidity sensors v 4. 6. 2 Gas sensors

4. 5 Solid fast-ion conductors 1 v Inoic transport comprises the movement of ions into vacant sites over substantial energy barrier that result in very low mobilities v Fast-ion conductors, optimal ionic conductors, superionic conductors v there clearly must be a supply of sites into which the mobile ion can move. lattice vacancies , features of lattice structure such as tunnels, underpopulated planes within which specific ions can move which a low activation energy v Important factors of movement : size and charge of mobile ions , size of the spaces within a lattice. v Small singly charged cations(Li+, La+) are mobile in a number of environments, in contrast with more highly charged and smaller cations. this is the polarization of the anions by the smaller more highly charged cations. This interaction constitutes a high-energy barrier to the movement of cations(chap 2. 6. 3). However, there are factors other than geometry and size that have important effects

4. 5 Solid fast-ion conductors 2 v ex)on a rigid sphere model, the interstices between the anions(radius r. A) in a face-centred cubic lattice would only allow penetration by a cation(0. 15 r. A). however, in the case of I- ions(radius 220 pm), interstices offer an aperture of only 34 pm radius, the transport of Li+ (r 3=55 pm) is significant and the room temperature ionic Conductivity of Li. I is 5× 10 -5 Sm-1 v This can be attributed to a number of factors 1. ions are not rigid spheres. 2. Simple concepts relating to the interaction of massive bodies are not applicable In detail to the interactions of ions. 3. Thermal energy will lead to random enlargements of the interstices and to the creation of anion and cation vacancies facilitating the passage of ions v Li. I melts at 450℃ so that at room temperature it is only 430 K below its melting point and the concentration of vacant sites will be high.

4. 5 Solid fast-ion conductors 3 v Rb. Ag 4 I 5 , a fast-ion conductor (in polycrystalline form) has an ionic conductivity due to Ag+ ions of 21 Sm-1 at 25 ℃ v even though silver has a large radius(r 6=115 pm), the Rb. Ag 4 I 5 structure is such as to offer apertures approaching this diameter for the Ag+ ions v Ionically conducting ceramic oxides are not as conductive as iodides and sulphides with their larger anions. v However, the oxygen conductor-zironia and the sodium-conductor and β’and β”-alumina are sufficiently conductive, particularly at elevated temperature to have been adopted for a number of applications. v In particular they can form the electrolytes in electrolytic cells which can be used both to measure the concentration of specific elements and as a means of storing electrical power.

4. 5 Solid fast-ion conductors 4 v e. m. f. E of cell which has a source of ions at a high concentration (activity a 1) on one side of an electrolyte and at a low concentration (activity a 2) on the other side is given by ΔGOT = -z. FE ΔGOT : standard free-energy change of the cell reaction at temperature F : Faraday constant(9. 649× 104 Cmol-1) v z : charge number of the ion In terms of the activity differences the change in free energy is ΔGOT =-RTln(a 1/a 2) • R: gas constant(8. 314 JK-1 mol-1) • a 1/a 2: by the ratio of gas pressures at the active electrodes on each side of the electrolyte or by the rate of the concentrations of ions in solution. v To obtain efficient conversion between chemical and electrical energy, the resistance of the electrolyte must be low, which is assisted by operation at high temperatures.

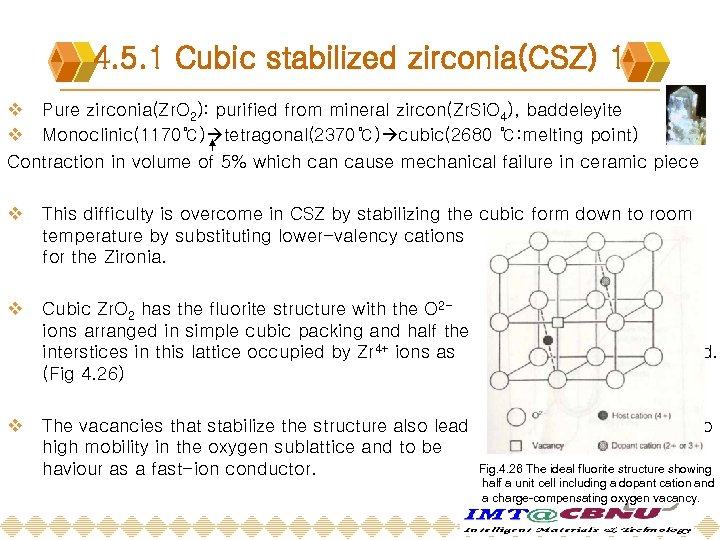

4. 5. 1 Cubic stabilized zirconia(CSZ) 1 v Pure zirconia(Zr. O 2): purified from mineral zircon(Zr. Si. O 4), baddeleyite v Monoclinic(1170℃) tetragonal(2370℃) cubic(2680 ℃: melting point) Contraction in volume of 5% which can cause mechanical failure in ceramic piece v This difficulty is overcome in CSZ by stabilizing the cubic form down to room temperature by substituting lower-valency cations for the Zironia. v Cubic Zr. O 2 has the fluorite structure with the O 2 ions arranged in simple cubic packing and half the interstices in this lattice occupied by Zr 4+ ions as (Fig 4. 26) v The vacancies that stabilize the structure also lead high mobility in the oxygen sublattice and to be haviour as a fast-ion conductor. indicated. to Fig. 4. 26 The ideal fluorite structure showing half a unit cell including a dopant cation and a charge-compensating oxygen vacancy.

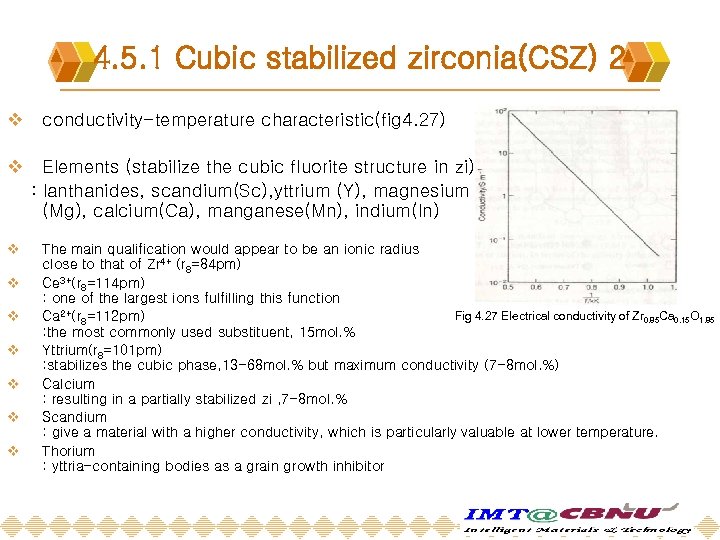

4. 5. 1 Cubic stabilized zirconia(CSZ) 2 v v v v v conductivity-temperature characteristic(fig 4. 27) Elements (stabilize the cubic fluorite structure in zi) : lanthanides, scandium(Sc), yttrium (Y), magnesium (Mg), calcium(Ca), manganese(Mn), indium(In) The main qualification would appear to be an ionic radius close to that of Zr 4+ (r 8=84 pm) Ce 3+(r 8=114 pm) : one of the largest ions fulfilling this function Fig 4. 27 Electrical conductivity of Zr 0. 85 Ca 0. 15 O 1. 85 Ca 2+(r 8=112 pm) : the most commonly used substituent, 15 mol. % Yttrium(r 8=101 pm) : stabilizes the cubic phase, 13 -68 mol. % but maximum conductivity (7 -8 mol. %) Calcium : resulting in a partially stabilized zi , 7 -8 mol. % Scandium : give a material with a higher conductivity, which is particularly valuable at lower temperature. Thorium : yttria-containing bodies as a grain growth inhibitor

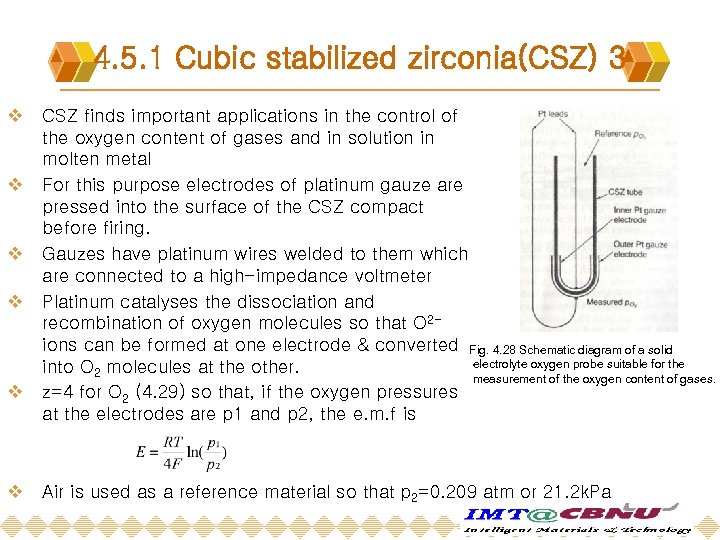

4. 5. 1 Cubic stabilized zirconia(CSZ) 3 v v v CSZ finds important applications in the control of the oxygen content of gases and in solution in molten metal For this purpose electrodes of platinum gauze are pressed into the surface of the CSZ compact before firing. Gauzes have platinum wires welded to them which are connected to a high-impedance voltmeter Platinum catalyses the dissociation and recombination of oxygen molecules so that O 2 ions can be formed at one electrode & converted Fig. 4. 28 Schematic diagram of a solid electrolyte oxygen probe suitable for the into O 2 molecules at the other. measurement of the oxygen content of gases. z=4 for O 2 (4. 29) so that, if the oxygen pressures at the electrodes are p 1 and p 2, the e. m. f is Air is used as a reference material so that p 2=0. 209 atm or 21. 2 k. Pa

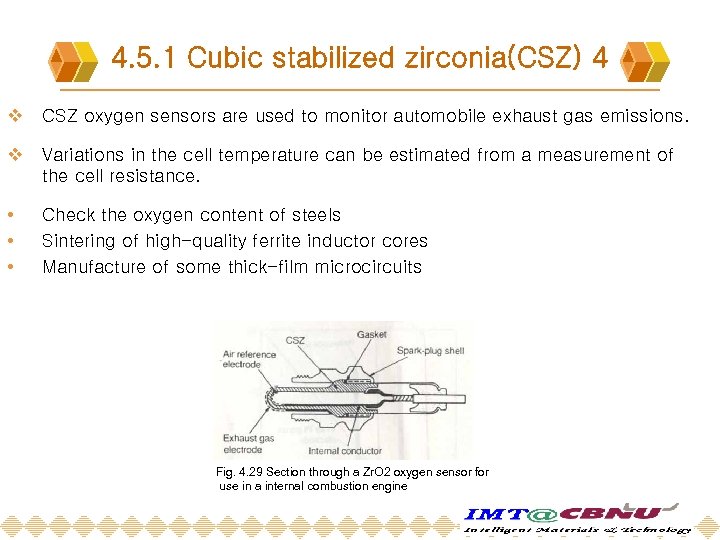

4. 5. 1 Cubic stabilized zirconia(CSZ) 4 v CSZ oxygen sensors are used to monitor automobile exhaust gas emissions. v Variations in the cell temperature can be estimated from a measurement of the cell resistance. • • • Check the oxygen content of steels Sintering of high-quality ferrite inductor cores Manufacture of some thick-film microcircuits Fig. 4. 29 Section through a Zr. O 2 oxygen sensor for use in a internal combustion engine

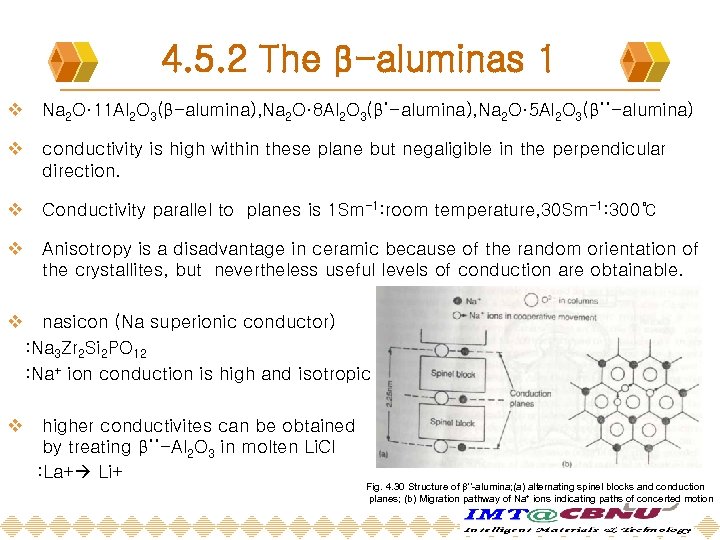

4. 5. 2 The β-aluminas 1 v Na 2 O· 11 Al 2 O 3(β-alumina), Na 2 O· 8 Al 2 O 3(β’-alumina), Na 2 O· 5 Al 2 O 3(β’’-alumina) v conductivity is high within these plane but negaligible in the perpendicular direction. v Conductivity parallel to planes is 1 Sm-1: room temperature, 30 Sm-1: 300℃ v Anisotropy is a disadvantage in ceramic because of the random orientation of the crystallites, but nevertheless useful levels of conduction are obtainable. v nasicon (Na superionic conductor) : Na 3 Zr 2 Si 2 PO 12 : Na+ ion conduction is high and isotropic v higher conductivites can be obtained by treating β’’-Al 2 O 3 in molten Li. Cl : La+ Li+ Fig. 4. 30 Structure of β’’-alumina; (a) alternating spinel blocks and conduction planes; (b) Migration pathway of Na+ ions indicating paths of concerted motion

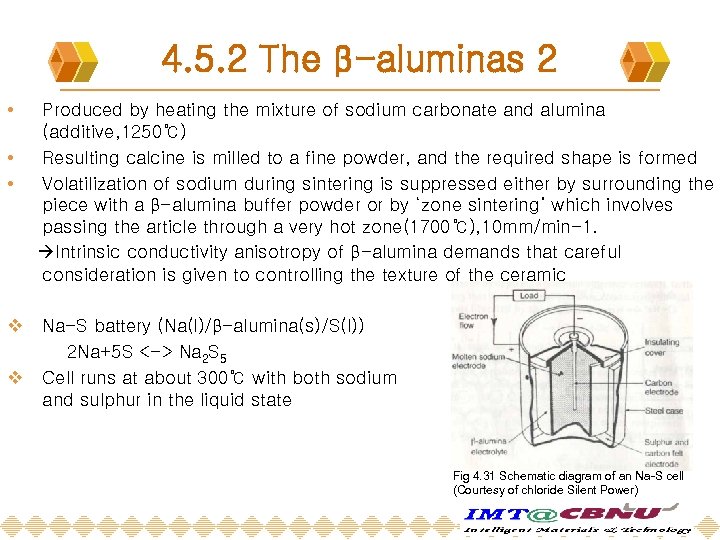

4. 5. 2 The β-aluminas 2 • • • v v Produced by heating the mixture of sodium carbonate and alumina (additive, 1250℃) Resulting calcine is milled to a fine powder, and the required shape is formed Volatilization of sodium during sintering is suppressed either by surrounding the piece with a β-alumina buffer powder or by ‘zone sintering’ which involves passing the article through a very hot zone(1700℃), 10 mm/min-1. Intrinsic conductivity anisotropy of β-alumina demands that careful consideration is given to controlling the texture of the ceramic Na-S battery (Na(l)/β-alumina(s)/S(l)) 2 Na+5 S <-> Na 2 S 5 Cell runs at about 300℃ with both sodium and sulphur in the liquid state Fig 4. 31 Schematic diagram of an Na-S cell (Courtesy of chloride Silent Power)

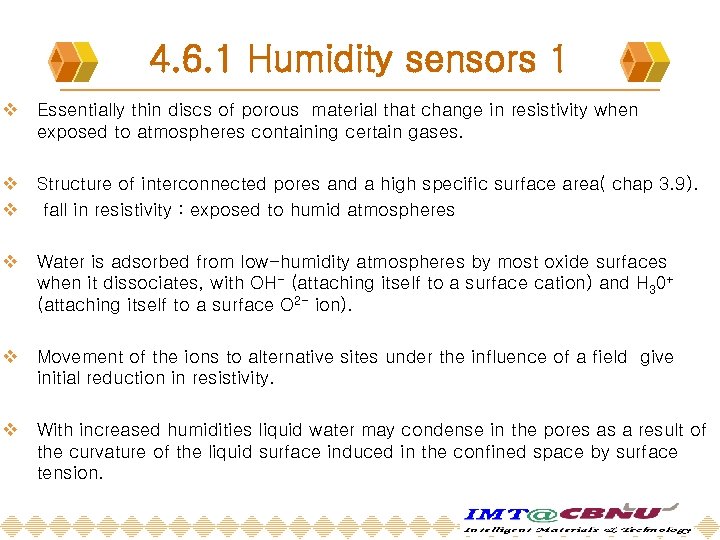

4. 6. 1 Humidity sensors 1 v Essentially thin discs of porous material that change in resistivity when exposed to atmospheres containing certain gases. v v Structure of interconnected pores and a high specific surface area( chap 3. 9). fall in resistivity : exposed to humid atmospheres v Water is adsorbed from low-humidity atmospheres by most oxide surfaces when it dissociates, with OH- (attaching itself to a surface cation) and H 30+ (attaching itself to a surface O 2 - ion). v Movement of the ions to alternative sites under the influence of a field give initial reduction in resistivity. v With increased humidities liquid water may condense in the pores as a result of the curvature of the liquid surface induced in the confined space by surface tension.

4. 6. 1 Humidity sensors 2 v v formation of liquid : pore diameter, surface tension , contact angle between the solid, liquid and gas phases. contact angle = zero, the vapour pressure (p) in equilibrium with a concave liquid meniscus relative to the vapour pressure (p 0) in equilibrium with a flat surface is given by γ: surface tension Vm: molar volume of the liquid R: gas constant T: temperature r: radius of curvature of the meniscus. v humidity (h) = 100 p/p 0 , diameter (d) of a pore in which water will condense is given by d=2 r, the relation between d and h is v To speed of response a humidity element , element must be thin in section and may contain a system of larger pores to reduce the length of the finer pore pathways into which gas must penetrate. Electrodes covering major surfaces must be porous. The response of the surfaces of the element to moisture must remain constant teat the sensor to a temperature of ~500℃ so that the surface is restored to a reproducible state. v

4. 6. 1 Humidity sensors 3 v Sensing element comprises a solid solution of Ti. O 2 in Mg. Cr 2 O 4 with a minor phase of Mg. Ti 2 O 5. v It is formed by mixing the constituent oxides, pressing them into compacts 0. 25 mm thick at the relatively low pressure of about 70 MPa(about 104 p. s. i) v Firing for several hours at about 1350 o. C to yield a sintered body (35% porosity). v Electrodes are Ru. O 2 with the minimum amount of added glaze for adhesion so that the layer is porous. v Mg. Cr 2 O 4 is a normal spinel with Mg 2+ (tetrahedral site), Cr 3+ (octahedral site). 30 mol. %Ti. O 2 can be incorporated without losing the spinel structure. v Ti 4+ and Mg 2+ ions occupy beighbouring octahedral sites and the excess charge is compensated by the formation of Cr 2+ ions which occupy tetrahedral sites. v It is a p-type semiconductor, in contrast with its behaviour as a gas sensor discussed below.

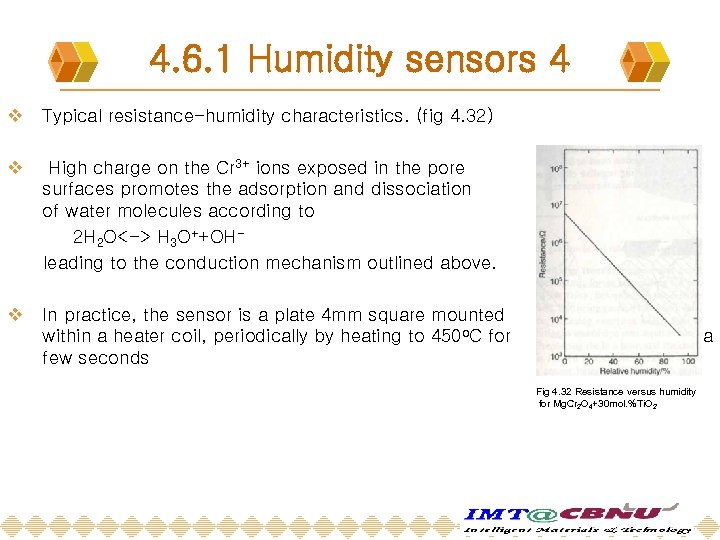

4. 6. 1 Humidity sensors 4 v Typical resistance-humidity characteristics. (fig 4. 32) v High charge on the Cr 3+ ions exposed in the pore surfaces promotes the adsorption and dissociation of water molecules according to 2 H 2 O<-> H 3 O++OHleading to the conduction mechanism outlined above. v In practice, the sensor is a plate 4 mm square mounted within a heater coil, periodically by heating to 450 o. C for few seconds a Fig 4. 32 Resistance versus humidity for Mg. Cr 2 O 4+30 mol. %Ti. O 2

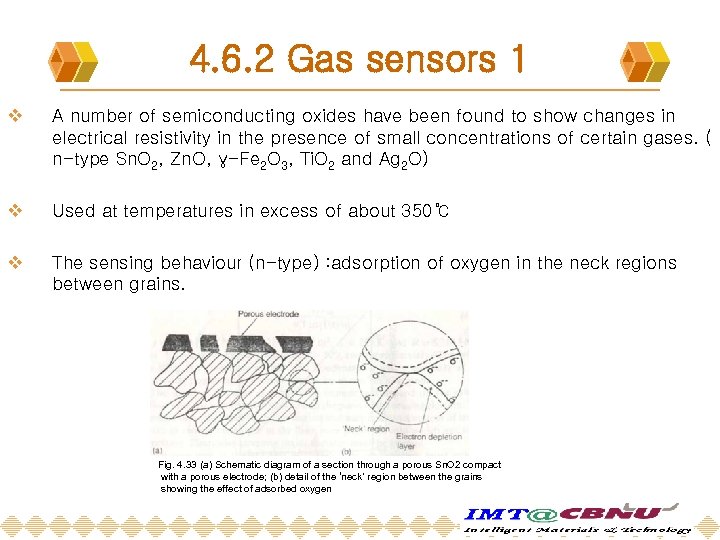

4. 6. 2 Gas sensors 1 v A number of semiconducting oxides have been found to show changes in electrical resistivity in the presence of small concentrations of certain gases. ( n-type Sn. O 2, Zn. O, γ-Fe 2 O 3, Ti. O 2 and Ag 2 O) v Used at temperatures in excess of about 350℃ v The sensing behaviour (n-type) : adsorption of oxygen in the neck regions between grains. Fig. 4. 33 (a) Schematic diagram of a section through a porous Sn. O 2 compact with a porous electrode; (b) detail of the ‘neck’ region between the grains showing the effect of adsorbed oxygen

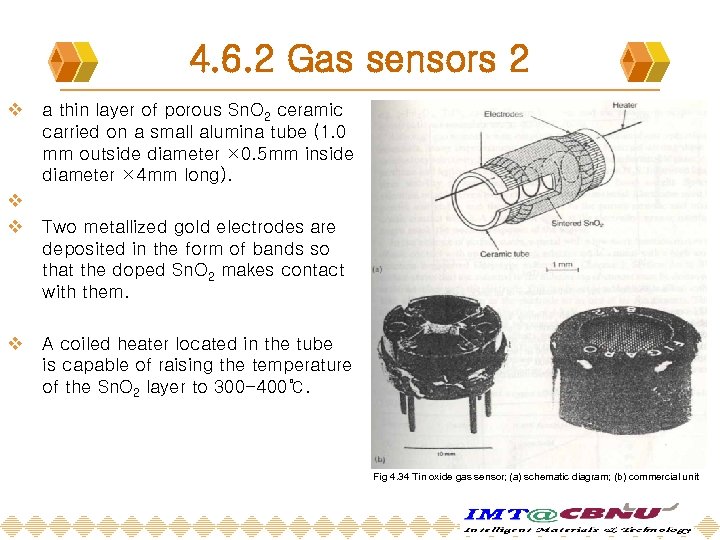

4. 6. 2 Gas sensors 2 v v a thin layer of porous Sn. O 2 ceramic carried on a small alumina tube (1. 0 mm outside diameter × 0. 5 mm inside diameter × 4 mm long). Two metallized gold electrodes are deposited in the form of bands so that the doped Sn. O 2 makes contact with them. A coiled heater located in the tube is capable of raising the temperature of the Sn. O 2 layer to 300 -400℃. Fig 4. 34 Tin oxide gas sensor; (a) schematic diagram; (b) commercial unit

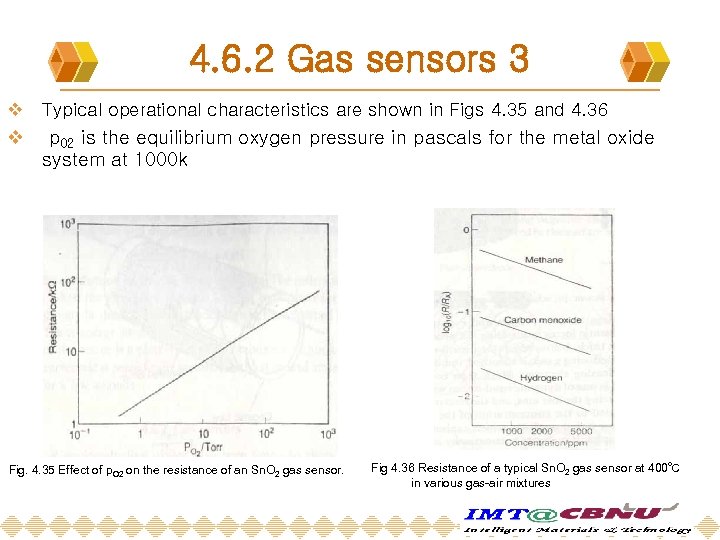

4. 6. 2 Gas sensors 3 v Typical operational characteristics are shown in Figs 4. 35 and 4. 36 v p 02 is the equilibrium oxygen pressure in pascals for the metal oxide system at 1000 k Fig. 4. 35 Effect of p. O 2 on the resistance of an Sn. O 2 gas sensor. Fig 4. 36 Resistance of a typical Sn. O 2 gas sensor at 400℃ in various gas-air mixtures

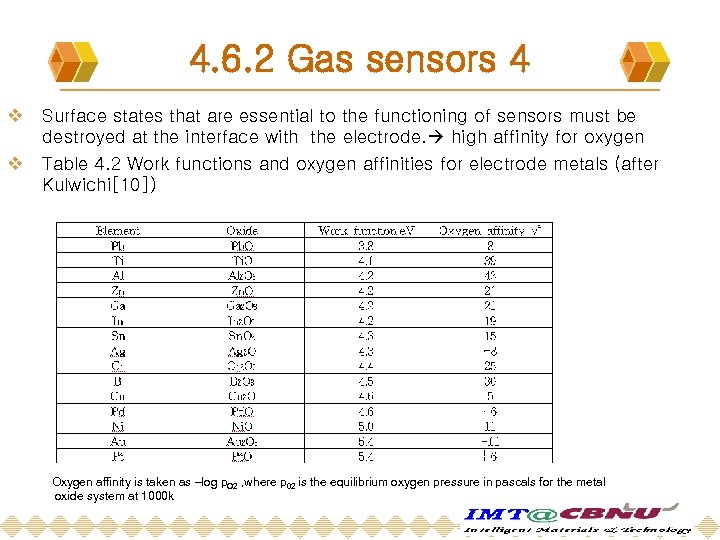

4. 6. 2 Gas sensors 4 v v Surface states that are essential to the functioning of sensors must be destroyed at the interface with the electrode. high affinity for oxygen Table 4. 2 Work functions and oxygen affinities for electrode metals (after Kulwichi[10]) Oxygen affinity is taken as –log p. O 2 , where p 02 is the equilibrium oxygen pressure in pascals for the metal oxide system at 1000 k

4b72035db5cfac1b74771e2285b2783c.ppt