13b3a49a1cdf56df6dbce88c3b7b4f4c.ppt

- Количество слайдов: 28

Workshop Exchange around motion control at radiation facilities _______ Status and plans in motion control at SOLEIL _______ Dominique Corruble May 11 th, 2011 Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 1

Workshop Exchange around motion control at radiation facilities _______ Status and plans in motion control at SOLEIL _______ Dominique Corruble May 11 th, 2011 Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 1

Summary. . 1) SOLEIL context and organization Soleil in few figures Computing division and ECA group 2) Motion control status Hardware architecture and products Software architecture and microcodes embedded Results 3) Plans Current developments New requirements and Revolution Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 2

Summary. . 1) SOLEIL context and organization Soleil in few figures Computing division and ECA group 2) Motion control status Hardware architecture and products Software architecture and microcodes embedded Results 3) Plans Current developments New requirements and Revolution Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 2

. . 1) SOLEIL context and organization Soleil in few figures Computing division and ECA group 2) Motion control status Hardware architecture and products Software architecture and microcodes embedded Results 3) Plans Current developments New requirements and Revolution Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 3

. . 1) SOLEIL context and organization Soleil in few figures Computing division and ECA group 2) Motion control status Hardware architecture and products Software architecture and microcodes embedded Results 3) Plans Current developments New requirements and Revolution Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 3

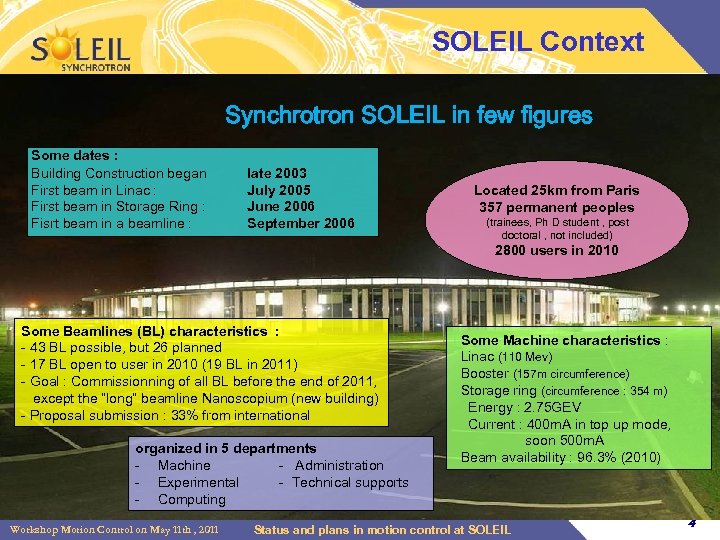

SOLEIL Context Synchrotron SOLEIL in few figures Some dates : Building Construction began First beam in Linac : First beam in Storage Ring : Fisrt beam in a beamline : late 2003 July 2005 June 2006 September 2006 Located 25 km from Paris 357 permanent peoples (trainees, Ph D student , post doctoral , not included) 2800 users in 2010 Some Beamlines (BL) characteristics : - 43 BL possible, but 26 planned - 17 BL open to user in 2010 (19 BL in 2011) - Goal : Commissionning of all BL before the end of 2011, except the “long” beamline Nanoscopium (new building) - Proposal submission : 33% from international organized in 5 departments - Machine - Administration - Experimental - Technical supports - Computing Workshop Motion Control on May 11 th , 2011 Some Machine characteristics : Linac (110 Mev) Booster (157 m circumference) Storage ring (circumference : 354 m) Energy : 2. 75 GEV Current : 400 m. A in top up mode, soon 500 m. A Beam availability : 96. 3% (2010) Status and plans in motion control at SOLEIL 4

SOLEIL Context Synchrotron SOLEIL in few figures Some dates : Building Construction began First beam in Linac : First beam in Storage Ring : Fisrt beam in a beamline : late 2003 July 2005 June 2006 September 2006 Located 25 km from Paris 357 permanent peoples (trainees, Ph D student , post doctoral , not included) 2800 users in 2010 Some Beamlines (BL) characteristics : - 43 BL possible, but 26 planned - 17 BL open to user in 2010 (19 BL in 2011) - Goal : Commissionning of all BL before the end of 2011, except the “long” beamline Nanoscopium (new building) - Proposal submission : 33% from international organized in 5 departments - Machine - Administration - Experimental - Technical supports - Computing Workshop Motion Control on May 11 th , 2011 Some Machine characteristics : Linac (110 Mev) Booster (157 m circumference) Storage ring (circumference : 354 m) Energy : 2. 75 GEV Current : 400 m. A in top up mode, soon 500 m. A Beam availability : 96. 3% (2010) Status and plans in motion control at SOLEIL 4

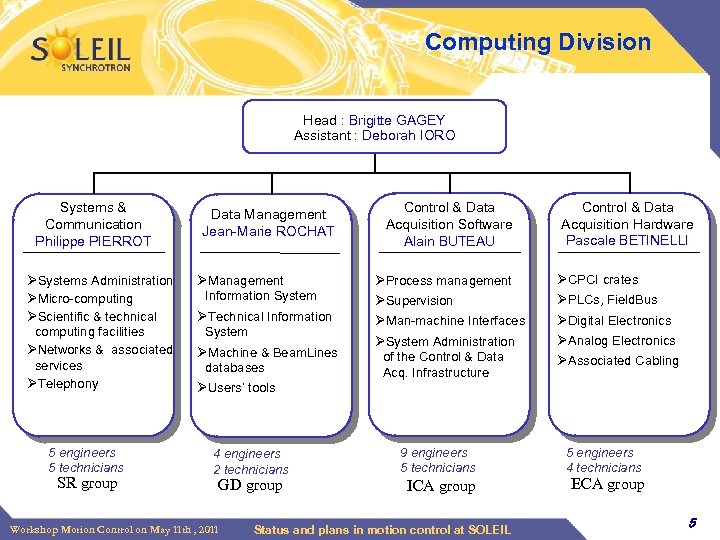

Computing Division Head : Brigitte GAGEY Assistant : Deborah IORO Systems & Communication Philippe PIERROT ØSystems Administration ØMicro-computing ØScientific & technical computing facilities ØNetworks & associated services ØTelephony 5 engineers 5 technicians SR group Data Management Jean-Marie ROCHAT Control & Data Acquisition Software Alain BUTEAU Control & Data Acquisition Hardware Pascale BETINELLI ØManagement Information System ØProcess management ØCPCI crates ØSupervision ØPLCs, Field. Bus ØTechnical Information System ØMan-machine Interfaces ØDigital Electronics ØSystem Administration of the Control & Data Acq. Infrastructure ØAnalog Electronics ØMachine & Beam. Lines databases ØAssociated Cabling ØUsers’ tools 4 engineers 2 technicians GD group Workshop Motion Control on May 11 th , 2011 9 engineers 5 technicians ICA group Status and plans in motion control at SOLEIL 5 engineers 4 technicians ECA group 5

Computing Division Head : Brigitte GAGEY Assistant : Deborah IORO Systems & Communication Philippe PIERROT ØSystems Administration ØMicro-computing ØScientific & technical computing facilities ØNetworks & associated services ØTelephony 5 engineers 5 technicians SR group Data Management Jean-Marie ROCHAT Control & Data Acquisition Software Alain BUTEAU Control & Data Acquisition Hardware Pascale BETINELLI ØManagement Information System ØProcess management ØCPCI crates ØSupervision ØPLCs, Field. Bus ØTechnical Information System ØMan-machine Interfaces ØDigital Electronics ØSystem Administration of the Control & Data Acq. Infrastructure ØAnalog Electronics ØMachine & Beam. Lines databases ØAssociated Cabling ØUsers’ tools 4 engineers 2 technicians GD group Workshop Motion Control on May 11 th , 2011 9 engineers 5 technicians ICA group Status and plans in motion control at SOLEIL 5 engineers 4 technicians ECA group 5

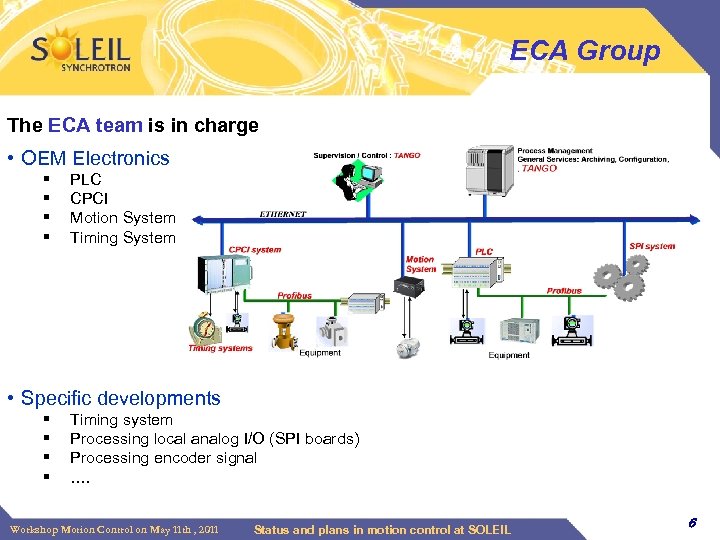

ECA Group The ECA team is in charge • OEM Electronics § § PLC CPCI Motion System Timing System • Specific developments § § Timing system Processing local analog I/O (SPI boards) Processing encoder signal …. Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 6

ECA Group The ECA team is in charge • OEM Electronics § § PLC CPCI Motion System Timing System • Specific developments § § Timing system Processing local analog I/O (SPI boards) Processing encoder signal …. Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 6

. . 1) SOLEIL context and organization Soleil in few figures Computing division and ECA group 2) Motion control status Hardware architecture and products Software architecture and microcodes embedded Results 3) Plans Current developments New requirements and Revolution Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 7

. . 1) SOLEIL context and organization Soleil in few figures Computing division and ECA group 2) Motion control status Hardware architecture and products Software architecture and microcodes embedded Results 3) Plans Current developments New requirements and Revolution Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 7

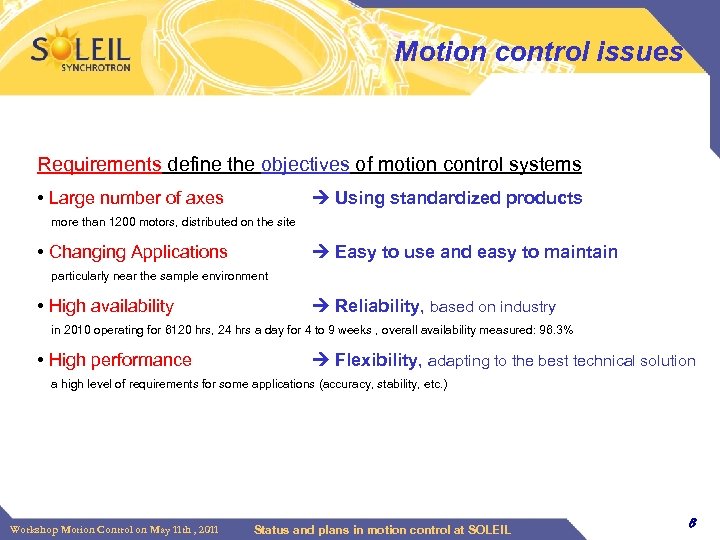

Motion control issues . Requirements define the objectives of motion control systems • Large number of axes Using standardized products more than 1200 motors, distributed on the site • Changing Applications Easy to use and easy to maintain particularly near the sample environment • High availability Reliability, based on industry in 2010 operating for 6120 hrs, 24 hrs a day for 4 to 9 weeks , overall availability measured: 96. 3% • High performance Flexibility, adapting to the best technical solution a high level of requirements for some applications (accuracy, stability, etc. ) Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 8

Motion control issues . Requirements define the objectives of motion control systems • Large number of axes Using standardized products more than 1200 motors, distributed on the site • Changing Applications Easy to use and easy to maintain particularly near the sample environment • High availability Reliability, based on industry in 2010 operating for 6120 hrs, 24 hrs a day for 4 to 9 weeks , overall availability measured: 96. 3% • High performance Flexibility, adapting to the best technical solution a high level of requirements for some applications (accuracy, stability, etc. ) Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 8

Standardization: first results • Stepper motor 4 phases, bipolar Adapted to main static positioning needs Open technology Reliable and easy to configure • Encoder incremental TTL, or absolute SSI or analog Industrial open standard • Control. Box Stand-alone rack independent from power unit integration of motion controller Multiaxis and easy to use, from a major company • Driver. Box power unit • Standardized Cables . . Workshop Motion Control on May 11 th , 2011 Rack for reliable power board based on industrial products Connectors and cables are clearly defined industrial products. Status and plans in motion control at SOLEIL 9

Standardization: first results • Stepper motor 4 phases, bipolar Adapted to main static positioning needs Open technology Reliable and easy to configure • Encoder incremental TTL, or absolute SSI or analog Industrial open standard • Control. Box Stand-alone rack independent from power unit integration of motion controller Multiaxis and easy to use, from a major company • Driver. Box power unit • Standardized Cables . . Workshop Motion Control on May 11 th , 2011 Rack for reliable power board based on industrial products Connectors and cables are clearly defined industrial products. Status and plans in motion control at SOLEIL 9

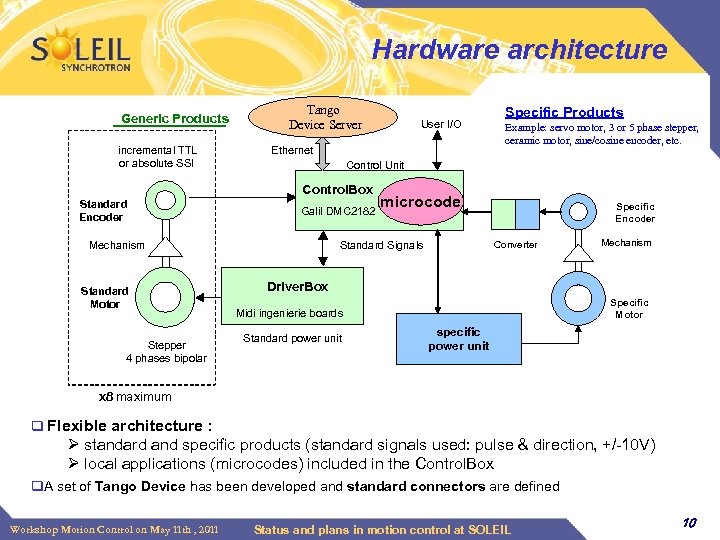

Hardware architecture Generic Products incremental TTL or absolute SSI Tango Device Server Ethernet Galil DMC 2182 Mechanism Standard Motor Stepper 4 phases bipolar Specific Products Example: servo motor, 3 or 5 phase stepper, ceramic motor, sine/cosine encoder, etc. Control Unit Control. Box Standard Encoder User I/O . . Local microcode applications Standard Signals Specific Encoder Converter Mechanism Driver. Box Specific Motor Midi ingenierie boards Standard power unit specific power unit x 8 maximum q Flexible architecture : Ø standard and specific products (standard signals used: pulse & direction, +/-10 V) Ø local applications (microcodes) included in the Control. Box q. A set of Tango Device has been developed and standard connectors are defined Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 10

Hardware architecture Generic Products incremental TTL or absolute SSI Tango Device Server Ethernet Galil DMC 2182 Mechanism Standard Motor Stepper 4 phases bipolar Specific Products Example: servo motor, 3 or 5 phase stepper, ceramic motor, sine/cosine encoder, etc. Control Unit Control. Box Standard Encoder User I/O . . Local microcode applications Standard Signals Specific Encoder Converter Mechanism Driver. Box Specific Motor Midi ingenierie boards Standard power unit specific power unit x 8 maximum q Flexible architecture : Ø standard and specific products (standard signals used: pulse & direction, +/-10 V) Ø local applications (microcodes) included in the Control. Box q. A set of Tango Device has been developed and standard connectors are defined Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 10

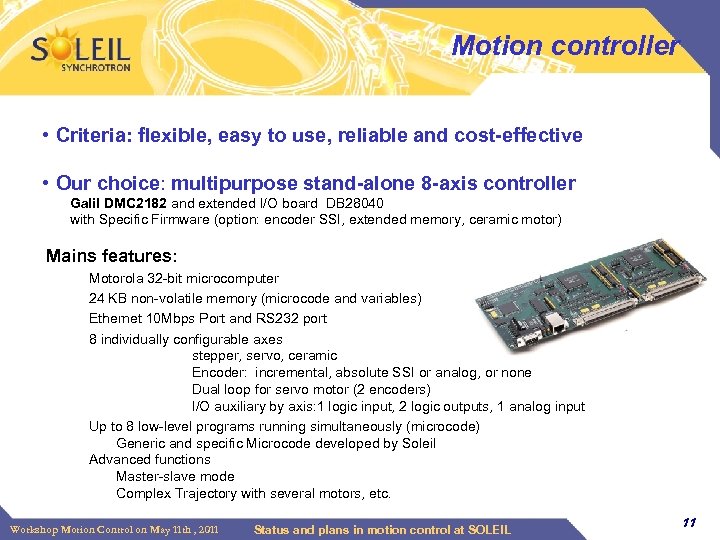

Motion controller . • Criteria: flexible, easy to use, reliable and cost-effective • Our choice: multipurpose stand-alone 8 -axis controller Galil DMC 2182 and extended I/O board DB 28040 with Specific Firmware (option: encoder SSI, extended memory, ceramic motor) Mains features: Motorola 32 -bit microcomputer 24 KB non-volatile memory (microcode and variables) Ethernet 10 Mbps Port and RS 232 port 8 individually configurable axes stepper, servo, ceramic Encoder: incremental, absolute SSI or analog, or none Dual loop for servo motor (2 encoders) I/O auxiliary by axis: 1 logic input, 2 logic outputs, 1 analog input Up to 8 low-level programs running simultaneously (microcode) Generic and specific Microcode developed by Soleil Advanced functions Master-slave mode Complex Trajectory with several motors, etc. Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 11

Motion controller . • Criteria: flexible, easy to use, reliable and cost-effective • Our choice: multipurpose stand-alone 8 -axis controller Galil DMC 2182 and extended I/O board DB 28040 with Specific Firmware (option: encoder SSI, extended memory, ceramic motor) Mains features: Motorola 32 -bit microcomputer 24 KB non-volatile memory (microcode and variables) Ethernet 10 Mbps Port and RS 232 port 8 individually configurable axes stepper, servo, ceramic Encoder: incremental, absolute SSI or analog, or none Dual loop for servo motor (2 encoders) I/O auxiliary by axis: 1 logic input, 2 logic outputs, 1 analog input Up to 8 low-level programs running simultaneously (microcode) Generic and specific Microcode developed by Soleil Advanced functions Master-slave mode Complex Trajectory with several motors, etc. Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 11

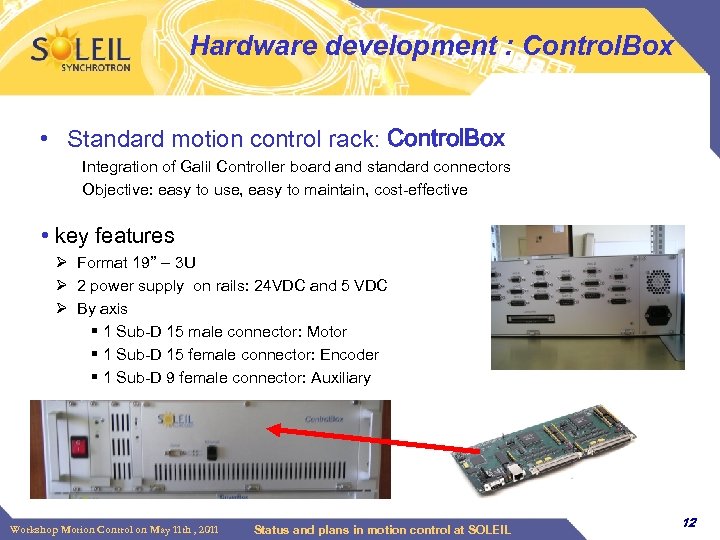

Hardware development : Control. Box . • Standard motion control rack: Control. Box Integration of Galil Controller board and standard connectors Objective: easy to use, easy to maintain, cost-effective • key features Ø Format 19’’ – 3 U Ø 2 power supply on rails: 24 VDC and 5 VDC Ø By axis § 1 Sub-D 15 male connector: Motor § 1 Sub-D 15 female connector: Encoder § 1 Sub-D 9 female connector: Auxiliary Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 12

Hardware development : Control. Box . • Standard motion control rack: Control. Box Integration of Galil Controller board and standard connectors Objective: easy to use, easy to maintain, cost-effective • key features Ø Format 19’’ – 3 U Ø 2 power supply on rails: 24 VDC and 5 VDC Ø By axis § 1 Sub-D 15 male connector: Motor § 1 Sub-D 15 female connector: Encoder § 1 Sub-D 9 female connector: Auxiliary Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 12

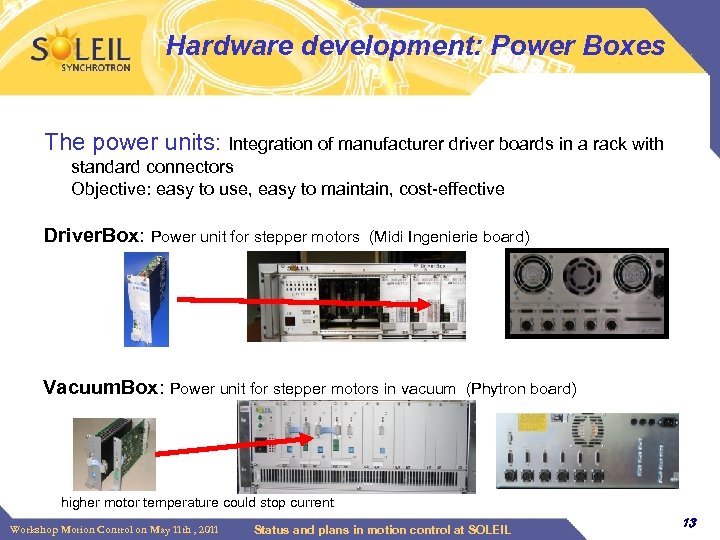

Hardware development: Power Boxes . The power units: Integration of manufacturer driver boards in a rack with standard connectors Objective: easy to use, easy to maintain, cost-effective Driver. Box: Power unit for stepper motors (Midi Ingenierie board) Vacuum. Box: Power unit for stepper motors in vacuum (Phytron board) higher motor temperature could stop current Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 13

Hardware development: Power Boxes . The power units: Integration of manufacturer driver boards in a rack with standard connectors Objective: easy to use, easy to maintain, cost-effective Driver. Box: Power unit for stepper motors (Midi Ingenierie board) Vacuum. Box: Power unit for stepper motors in vacuum (Phytron board) higher motor temperature could stop current Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 13

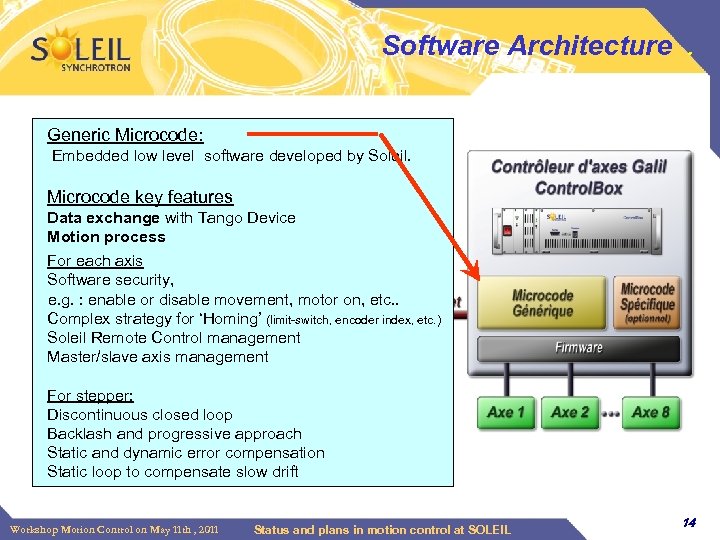

Software Architecture. Generic Microcode: Embedded low level software developed by Soleil. Microcode key features Data exchange with Tango Device Motion process For each axis Software security, e. g. : enable or disable movement, motor on, etc. . Complex strategy for ‘Homing’ (limit-switch, encoder index, etc. ) Soleil Remote Control management Master/slave axis management For stepper: Discontinuous closed loop Backlash and progressive approach Static and dynamic error compensation Static loop to compensate slow drift Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 14

Software Architecture. Generic Microcode: Embedded low level software developed by Soleil. Microcode key features Data exchange with Tango Device Motion process For each axis Software security, e. g. : enable or disable movement, motor on, etc. . Complex strategy for ‘Homing’ (limit-switch, encoder index, etc. ) Soleil Remote Control management Master/slave axis management For stepper: Discontinuous closed loop Backlash and progressive approach Static and dynamic error compensation Static loop to compensate slow drift Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 14

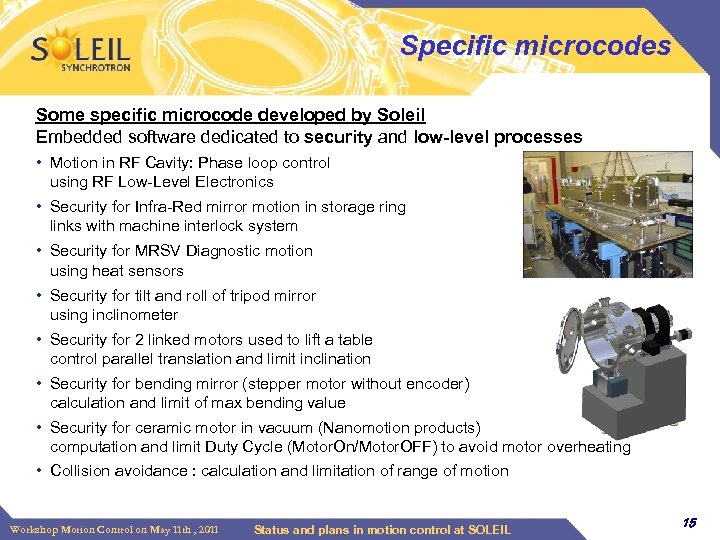

Specific microcodes . Some specific microcode developed by Soleil Embedded software dedicated to security and low-level processes • Motion in RF Cavity: Phase loop control using RF Low-Level Electronics • Security for Infra-Red mirror motion in storage ring links with machine interlock system • Security for MRSV Diagnostic motion using heat sensors • Security for tilt and roll of tripod mirror using inclinometer • Security for 2 linked motors used to lift a table control parallel translation and limit inclination • Security for bending mirror (stepper motor without encoder) calculation and limit of max bending value • Security for ceramic motor in vacuum (Nanomotion products) computation and limit Duty Cycle (Motor. On/Motor. OFF) to avoid motor overheating • Collision avoidance : calculation and limitation of range of motion Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 15

Specific microcodes . Some specific microcode developed by Soleil Embedded software dedicated to security and low-level processes • Motion in RF Cavity: Phase loop control using RF Low-Level Electronics • Security for Infra-Red mirror motion in storage ring links with machine interlock system • Security for MRSV Diagnostic motion using heat sensors • Security for tilt and roll of tripod mirror using inclinometer • Security for 2 linked motors used to lift a table control parallel translation and limit inclination • Security for bending mirror (stepper motor without encoder) calculation and limit of max bending value • Security for ceramic motor in vacuum (Nanomotion products) computation and limit Duty Cycle (Motor. On/Motor. OFF) to avoid motor overheating • Collision avoidance : calculation and limitation of range of motion Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 15

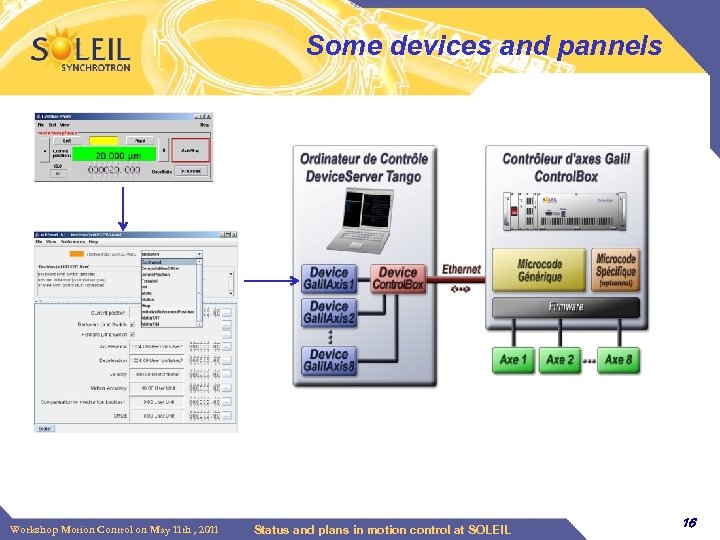

Some devices and pannels Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 16

Some devices and pannels Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 16

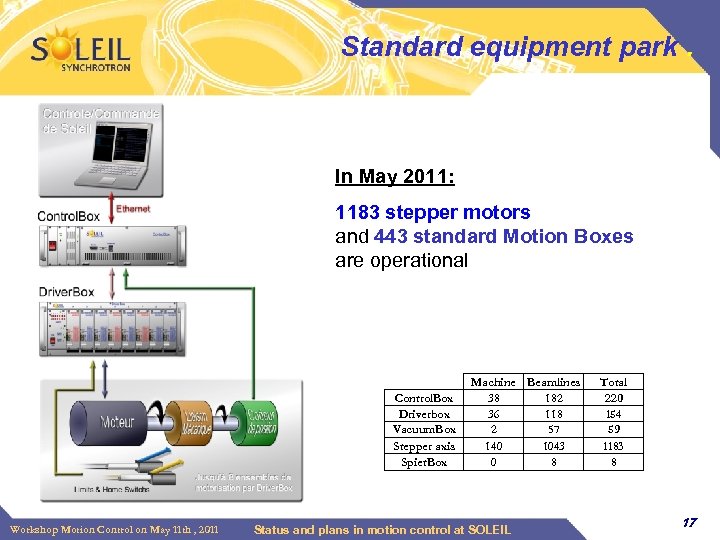

Standard equipment park. In May 2011: 1183 stepper motors and 443 standard Motion Boxes are operational Control. Box Driverbox Vacuum. Box Stepper axis Spiet. Box Workshop Motion Control on May 11 th , 2011 Machine Beamlines 38 182 36 118 2 57 140 1043 0 8 Status and plans in motion control at SOLEIL Total 220 154 59 1183 8 17

Standard equipment park. In May 2011: 1183 stepper motors and 443 standard Motion Boxes are operational Control. Box Driverbox Vacuum. Box Stepper axis Spiet. Box Workshop Motion Control on May 11 th , 2011 Machine Beamlines 38 182 36 118 2 57 140 1043 0 8 Status and plans in motion control at SOLEIL Total 220 154 59 1183 8 17

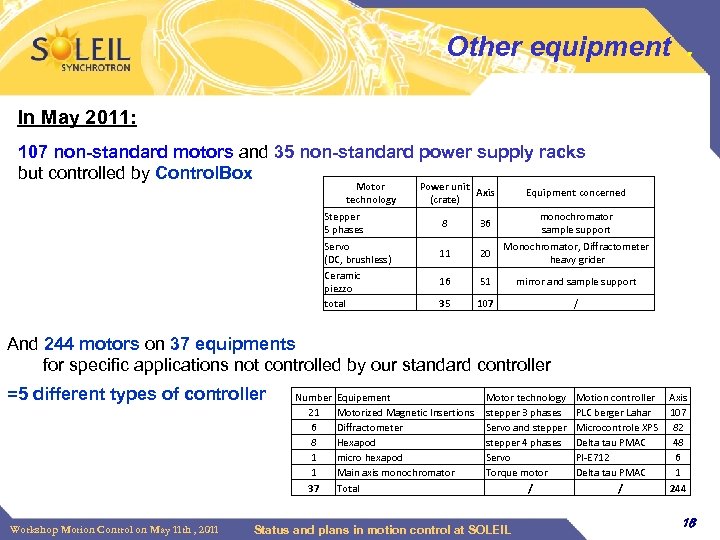

Other equipment. In May 2011: 107 non-standard motors and 35 non-standard power supply racks but controlled by Control. Box Motor technology Stepper 5 phases Servo (DC, brushless) Ceramic piezzo total Power unit Axis (crate) Equipment concerned 8 36 monochromator sample support 11 20 Monochromator, Diffractometer heavy grider 16 51 mirror and sample support 35 107 / And 244 motors on 37 equipments for specific applications not controlled by our standard controller =5 different types of controller Workshop Motion Control on May 11 th , 2011 Number 21 6 8 1 1 37 Equipement Motorized Magnetic Insertions Diffractometer Hexapod micro hexapod Main axis monochromator Total Motor technology stepper 3 phases Servo and stepper 4 phases Servo Torque motor / Status and plans in motion control at SOLEIL Motion controller PLC berger Lahar Microcontrole XPS Delta tau PMAC PI-E 712 Delta tau PMAC / Axis 107 82 48 6 1 244 18

Other equipment. In May 2011: 107 non-standard motors and 35 non-standard power supply racks but controlled by Control. Box Motor technology Stepper 5 phases Servo (DC, brushless) Ceramic piezzo total Power unit Axis (crate) Equipment concerned 8 36 monochromator sample support 11 20 Monochromator, Diffractometer heavy grider 16 51 mirror and sample support 35 107 / And 244 motors on 37 equipments for specific applications not controlled by our standard controller =5 different types of controller Workshop Motion Control on May 11 th , 2011 Number 21 6 8 1 1 37 Equipement Motorized Magnetic Insertions Diffractometer Hexapod micro hexapod Main axis monochromator Total Motor technology stepper 3 phases Servo and stepper 4 phases Servo Torque motor / Status and plans in motion control at SOLEIL Motion controller PLC berger Lahar Microcontrole XPS Delta tau PMAC PI-E 712 Delta tau PMAC / Axis 107 82 48 6 1 244 18

Results . At the present time, the initial objectives have been achieved and the motion systems work Ø Costs are controlled and no delay in providing working systems Ø Reliable hardware: Few items of equipment returned to supplier Galil auxiliary I/O board and Power 5 VDC of Control. Box are more sensitive but rate is tolerable (5%) ØEfficient and reliable software: very few interventions during operation 2 completely different versions for satisfactory results. Ethernet communication stability problem resolved Ø Performances are sufficient today for almost all applications Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 19

Results . At the present time, the initial objectives have been achieved and the motion systems work Ø Costs are controlled and no delay in providing working systems Ø Reliable hardware: Few items of equipment returned to supplier Galil auxiliary I/O board and Power 5 VDC of Control. Box are more sensitive but rate is tolerable (5%) ØEfficient and reliable software: very few interventions during operation 2 completely different versions for satisfactory results. Ethernet communication stability problem resolved Ø Performances are sufficient today for almost all applications Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 19

. . 1) SOLEIL context and organization Soleil in few figures Computing division and ECA group 2) Motion control status Hardware architecture and products Software architecture and microcodes embedded Results 3) Plans Current developments New requirements and Revolution Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 20

. . 1) SOLEIL context and organization Soleil in few figures Computing division and ECA group 2) Motion control status Hardware architecture and products Software architecture and microcodes embedded Results 3) Plans Current developments New requirements and Revolution Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 20

microcode developments Low level Software • Specific Microcode: Biaxial tensile machine Axis management to control mechanical force and deformation • Specific Microcode: collision avoidance 2 axis Calculation and limitation of range of motion for simple applications, we can develop and implement a specific firmware very shortly. Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 21

microcode developments Low level Software • Specific Microcode: Biaxial tensile machine Axis management to control mechanical force and deformation • Specific Microcode: collision avoidance 2 axis Calculation and limitation of range of motion for simple applications, we can develop and implement a specific firmware very shortly. Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 21

Servo. Box: New power unit for servo motors Rack very similar to Driver. Box Directly compatible with Control. Box Servo. Box contains • Standardized connectors • Power supply: 24 VDC (logic) et 48 VDC (1 KW to motor) • Fans and back plane board • 4 slots for 4 power board Ø Preliminary study and specification written by Soleil 5 rack manufactured and available Power Board SDB 10 based on an Elmo Whistle OEM component Numeric amplifier for DC or brushless motor Rated output current: 10 A (Voltage 48 V) Feed back by resolver or incremental encoder Signals managed: limit switch, thermal sensor, brake Ø Entire design by Soleil (electronics and mechanics) Prototype debugging in progress Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 22

Servo. Box: New power unit for servo motors Rack very similar to Driver. Box Directly compatible with Control. Box Servo. Box contains • Standardized connectors • Power supply: 24 VDC (logic) et 48 VDC (1 KW to motor) • Fans and back plane board • 4 slots for 4 power board Ø Preliminary study and specification written by Soleil 5 rack manufactured and available Power Board SDB 10 based on an Elmo Whistle OEM component Numeric amplifier for DC or brushless motor Rated output current: 10 A (Voltage 48 V) Feed back by resolver or incremental encoder Signals managed: limit switch, thermal sensor, brake Ø Entire design by Soleil (electronics and mechanics) Prototype debugging in progress Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 22

SPI Board Package What is the SPI* board package? – This is a set of electronic boards developed by the ECA group. These boards can be connected together in a daisy-chain manner and communicate with the controller via SPI Bus. Objective – – To obtain a platform allowing us to build the specific solution with simple and open tools. To provide solutions for applications with synchronization requirements (continuous scan). To implement the process at a low level, that is advantageous for us to obtain the best performance. To connect easily to the Soleil control network. This platform enables us to deliver solutions for applications with an analog interface or motion interface (encoder side). * Serial Peripheral Interface Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 23

SPI Board Package What is the SPI* board package? – This is a set of electronic boards developed by the ECA group. These boards can be connected together in a daisy-chain manner and communicate with the controller via SPI Bus. Objective – – To obtain a platform allowing us to build the specific solution with simple and open tools. To provide solutions for applications with synchronization requirements (continuous scan). To implement the process at a low level, that is advantageous for us to obtain the best performance. To connect easily to the Soleil control network. This platform enables us to deliver solutions for applications with an analog interface or motion interface (encoder side). * Serial Peripheral Interface Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 23

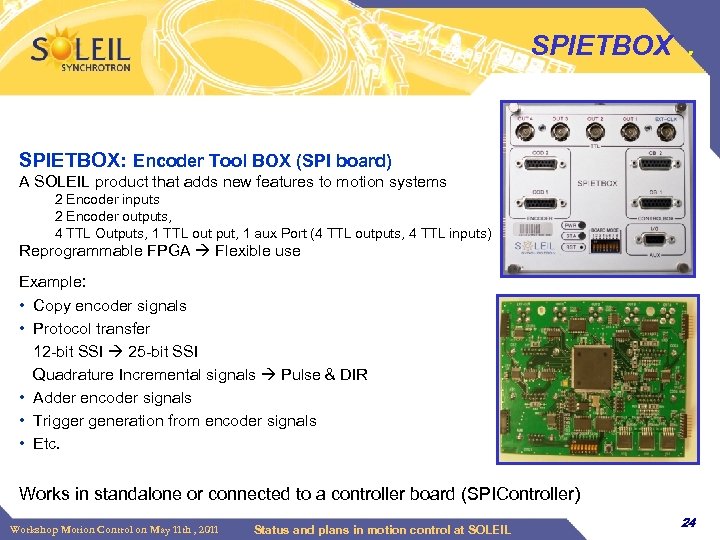

SPIETBOX. SPIETBOX: Encoder Tool BOX (SPI board) A SOLEIL product that adds new features to motion systems 2 Encoder inputs 2 Encoder outputs, 4 TTL Outputs, 1 TTL out put, 1 aux Port (4 TTL outputs, 4 TTL inputs) Reprogrammable FPGA Flexible use Example: • Copy encoder signals • Protocol transfer 12 -bit SSI 25 -bit SSI Quadrature Incremental signals Pulse & DIR • Adder encoder signals • Trigger generation from encoder signals • Etc. Works in standalone or connected to a controller board (SPIController) Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 24

SPIETBOX. SPIETBOX: Encoder Tool BOX (SPI board) A SOLEIL product that adds new features to motion systems 2 Encoder inputs 2 Encoder outputs, 4 TTL Outputs, 1 TTL out put, 1 aux Port (4 TTL outputs, 4 TTL inputs) Reprogrammable FPGA Flexible use Example: • Copy encoder signals • Protocol transfer 12 -bit SSI 25 -bit SSI Quadrature Incremental signals Pulse & DIR • Adder encoder signals • Trigger generation from encoder signals • Etc. Works in standalone or connected to a controller board (SPIController) Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 24

New requirements Control HEXAPOD - Stewart Platform 6 axis Generate and control complex trajectories Integration of direct and reverse kinematic equations into standard motion controller and devices. To be able to replace controller being used with a standard solution Nanopositioning Be able to position an axis at few nanometers and keep this position by compensating externals disturbances. A new loop with external sensor (eg interferometer) Synchronization Be able to synchronize several axis and several sensors to make continous scan over comples trajectories. Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 25

New requirements Control HEXAPOD - Stewart Platform 6 axis Generate and control complex trajectories Integration of direct and reverse kinematic equations into standard motion controller and devices. To be able to replace controller being used with a standard solution Nanopositioning Be able to position an axis at few nanometers and keep this position by compensating externals disturbances. A new loop with external sensor (eg interferometer) Synchronization Be able to synchronize several axis and several sensors to make continous scan over comples trajectories. Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 25

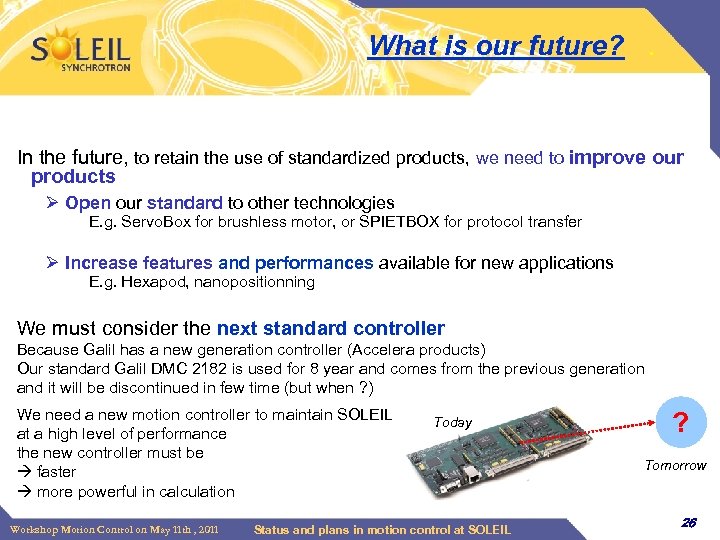

What is our future? . In the future, to retain the use of standardized products, we need to improve our products Ø Open our standard to other technologies E. g. Servo. Box for brushless motor, or SPIETBOX for protocol transfer Ø Increase features and performances available for new applications E. g. Hexapod, nanopositionning We must consider the next standard controller Because Galil has a new generation controller (Accelera products) Our standard Galil DMC 2182 is used for 8 year and comes from the previous generation and it will be discontinued in few time (but when ? ) We need a new motion controller to maintain SOLEIL at a high level of performance the new controller must be faster more powerful in calculation Workshop Motion Control on May 11 th , 2011 Today Status and plans in motion control at SOLEIL ? Tomorrow 26

What is our future? . In the future, to retain the use of standardized products, we need to improve our products Ø Open our standard to other technologies E. g. Servo. Box for brushless motor, or SPIETBOX for protocol transfer Ø Increase features and performances available for new applications E. g. Hexapod, nanopositionning We must consider the next standard controller Because Galil has a new generation controller (Accelera products) Our standard Galil DMC 2182 is used for 8 year and comes from the previous generation and it will be discontinued in few time (but when ? ) We need a new motion controller to maintain SOLEIL at a high level of performance the new controller must be faster more powerful in calculation Workshop Motion Control on May 11 th , 2011 Today Status and plans in motion control at SOLEIL ? Tomorrow 26

Revolution SOLEIL starts an upgrade of its motion controller MAX IV needs to define an up-to-date motion system architecture and to select a controller. SOLEIL and MAX IV have similar requirements - reliable, - performing - flexible & similar guidelines the main idea is “costs & time effective “ that means - no or few in-house development - standardization of hardware - modular solution - ready to use and complete solution So we start a technical collaboration to work together on this REVOLUTION REconsider V arious contr. OLler for yo. Ur mo. TION Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 27

Revolution SOLEIL starts an upgrade of its motion controller MAX IV needs to define an up-to-date motion system architecture and to select a controller. SOLEIL and MAX IV have similar requirements - reliable, - performing - flexible & similar guidelines the main idea is “costs & time effective “ that means - no or few in-house development - standardization of hardware - modular solution - ready to use and complete solution So we start a technical collaboration to work together on this REVOLUTION REconsider V arious contr. OLler for yo. Ur mo. TION Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 27

Questions . Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 28

Questions . Workshop Motion Control on May 11 th , 2011 Status and plans in motion control at SOLEIL 28