Topic 4. Capacity Planning Lecturer: Nazarov Nikita Constantinovich

![Evaluating Capacity Alternatives Cost-Volume Formulas TC=FC+(VCxQ) TR=RxQ P=TR–TC P=(RXQ)–[FC+(VCXQ)] Volume=(SP+FC)/(R-VC) QBEP=FC/(R-VC) Evaluating Capacity Alternatives Cost-Volume Formulas TC=FC+(VCxQ) TR=RxQ P=TR–TC P=(RXQ)–[FC+(VCXQ)] Volume=(SP+FC)/(R-VC) QBEP=FC/(R-VC)](https://present5.com/presentacii-2/20171208\14394-topic_4_2.ppt\14394-topic_4_2_23.jpg)

14394-topic_4_2.ppt

- Количество слайдов: 29

Topic 4. Capacity Planning Lecturer: Nazarov Nikita Constantinovich

Topic 4. Capacity Planning Lecturer: Nazarov Nikita Constantinovich

Structure of topic 1 2 Capacity planning 3 Process Of Capacity Planning 4 The Essence of Capacity Manufacturing and Service Systems

Structure of topic 1 2 Capacity planning 3 Process Of Capacity Planning 4 The Essence of Capacity Manufacturing and Service Systems

Manufacturing System Manufacturing systems produce standardized products in large volumes. finite capacity contribute fixed costs variable costs are added as labour productivity is measurable quantity.

Manufacturing System Manufacturing systems produce standardized products in large volumes. finite capacity contribute fixed costs variable costs are added as labour productivity is measurable quantity.

Service Systems Service systems present more uncertainty with respect to both capacity and costs. services are produced and consumed in the presence of the customer services must be sufficiently flexible to accommodate a highly variable demand many services involves professional or intellectual services judgments that are not easily standardized. difficult to accumulate costs and measure the productivity of the services.

Service Systems Service systems present more uncertainty with respect to both capacity and costs. services are produced and consumed in the presence of the customer services must be sufficiently flexible to accommodate a highly variable demand many services involves professional or intellectual services judgments that are not easily standardized. difficult to accumulate costs and measure the productivity of the services.

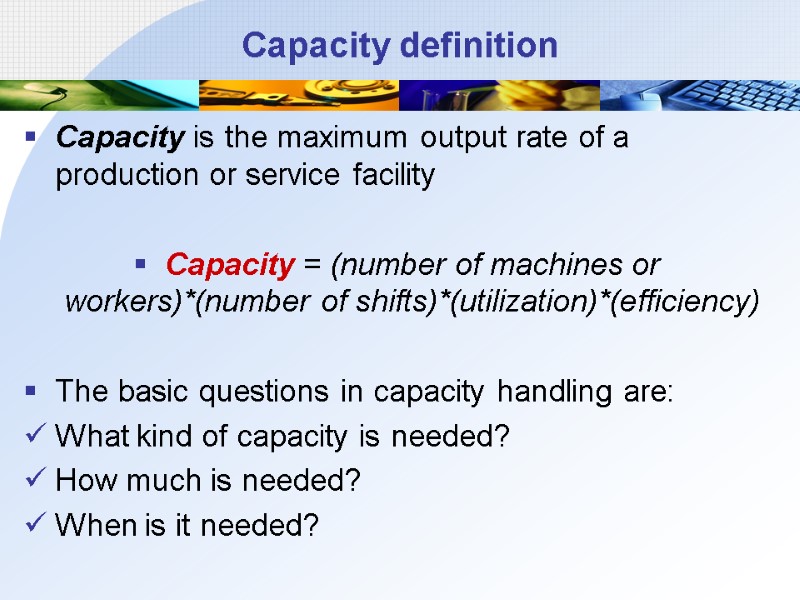

Capacity definition Capacity is the maximum output rate of a production or service facility Capacity = (number of machines or workers)*(number of shifts)*(utilization)*(efficiency) The basic questions in capacity handling are: What kind of capacity is needed? How much is needed? When is it needed?

Capacity definition Capacity is the maximum output rate of a production or service facility Capacity = (number of machines or workers)*(number of shifts)*(utilization)*(efficiency) The basic questions in capacity handling are: What kind of capacity is needed? How much is needed? When is it needed?

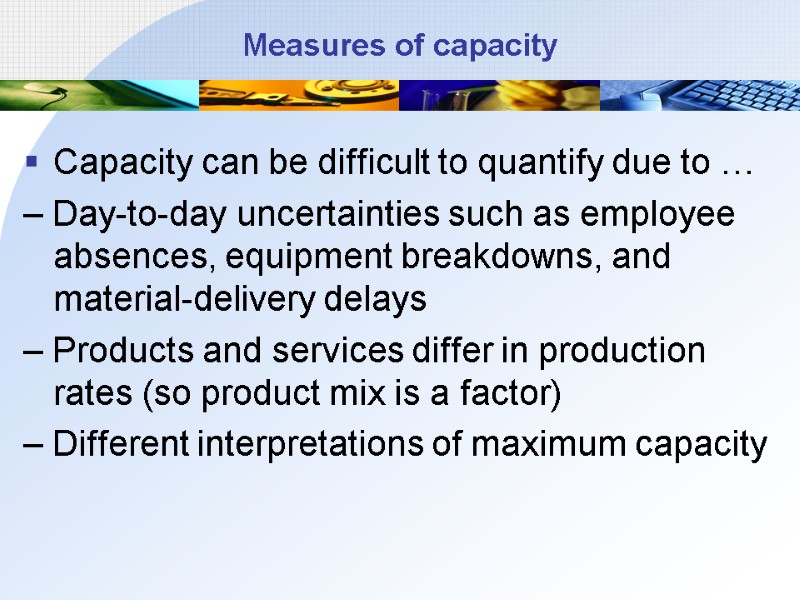

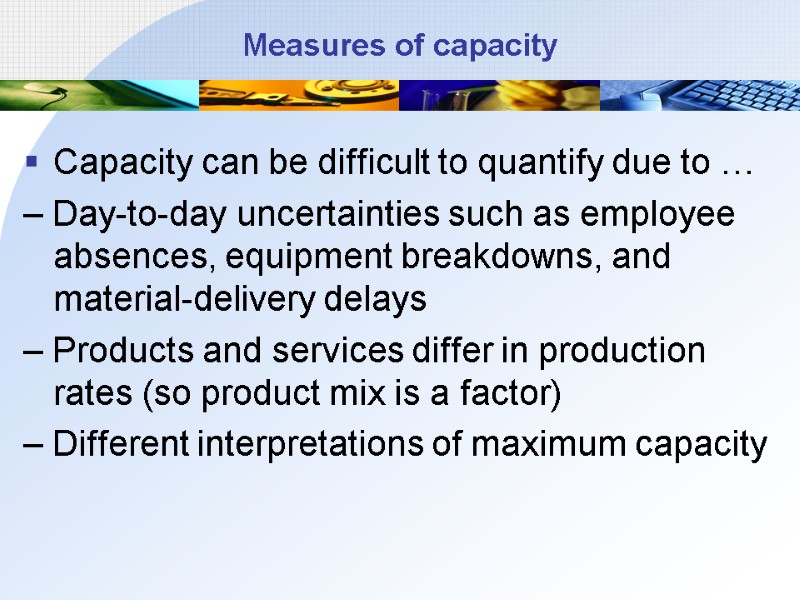

Measures of capacity Capacity can be difficult to quantify due to … – Day-to-day uncertainties such as employee absences, equipment breakdowns, and material-delivery delays – Products and services differ in production rates (so product mix is a factor) – Different interpretations of maximum capacity

Measures of capacity Capacity can be difficult to quantify due to … – Day-to-day uncertainties such as employee absences, equipment breakdowns, and material-delivery delays – Products and services differ in production rates (so product mix is a factor) – Different interpretations of maximum capacity

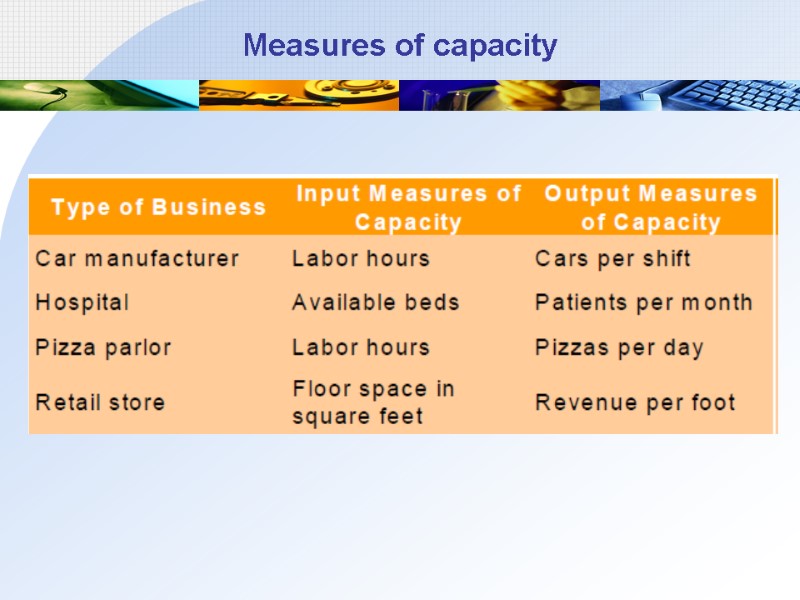

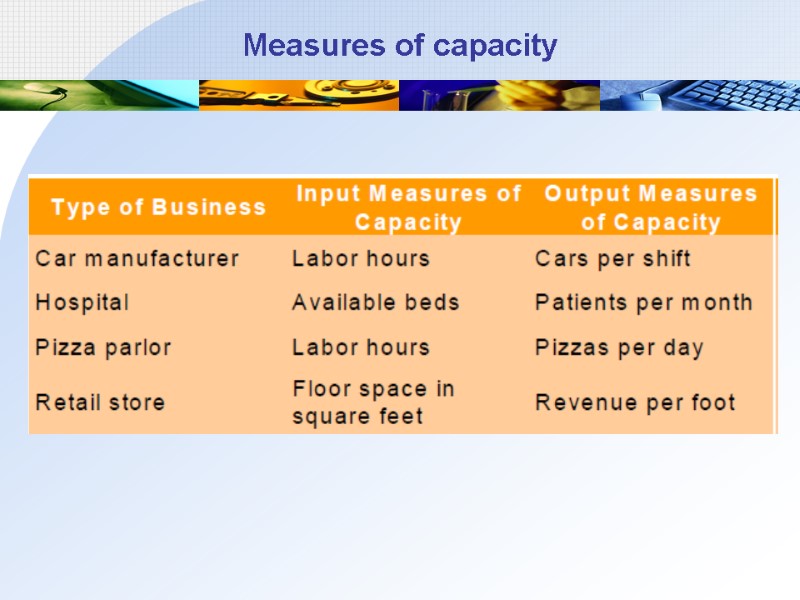

Measures of capacity

Measures of capacity

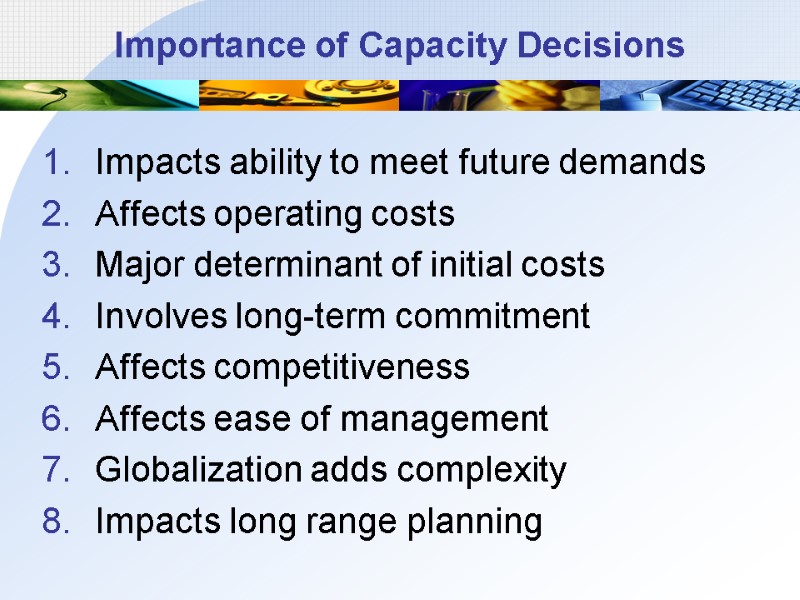

Importance of Capacity Decisions Impacts ability to meet future demands Affects operating costs Major determinant of initial costs Involves long-term commitment Affects competitiveness Affects ease of management Globalization adds complexity Impacts long range planning

Importance of Capacity Decisions Impacts ability to meet future demands Affects operating costs Major determinant of initial costs Involves long-term commitment Affects competitiveness Affects ease of management Globalization adds complexity Impacts long range planning

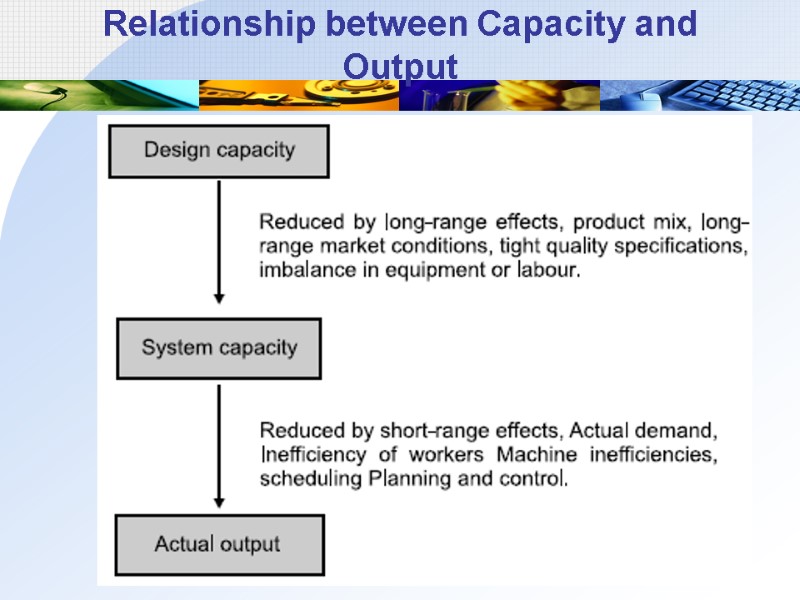

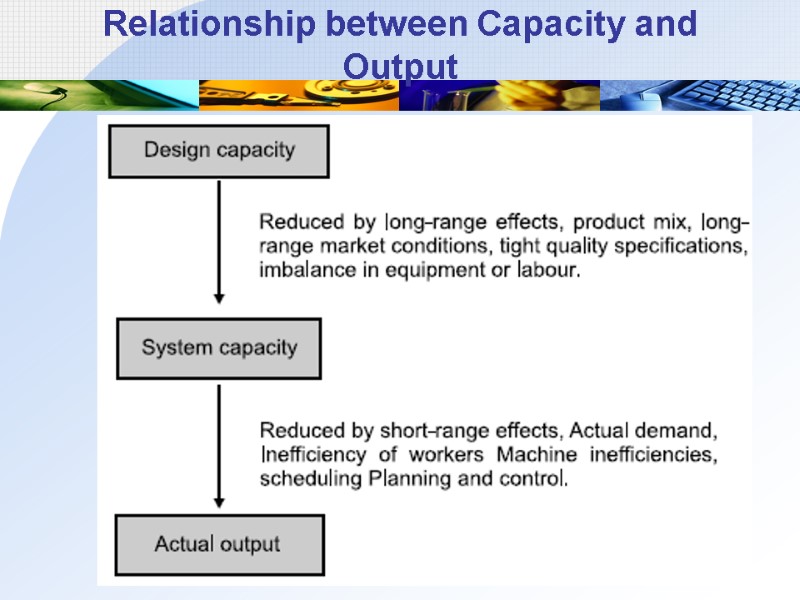

Relationship between Capacity and Output

Relationship between Capacity and Output

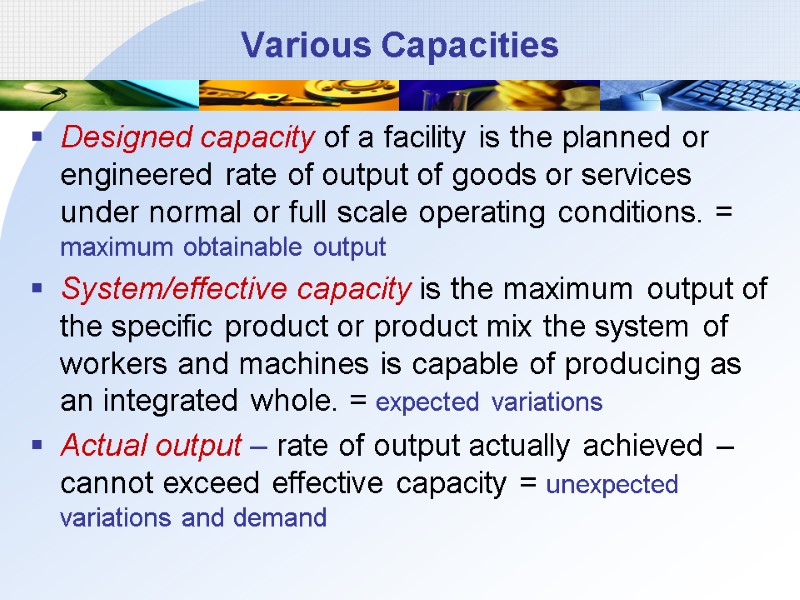

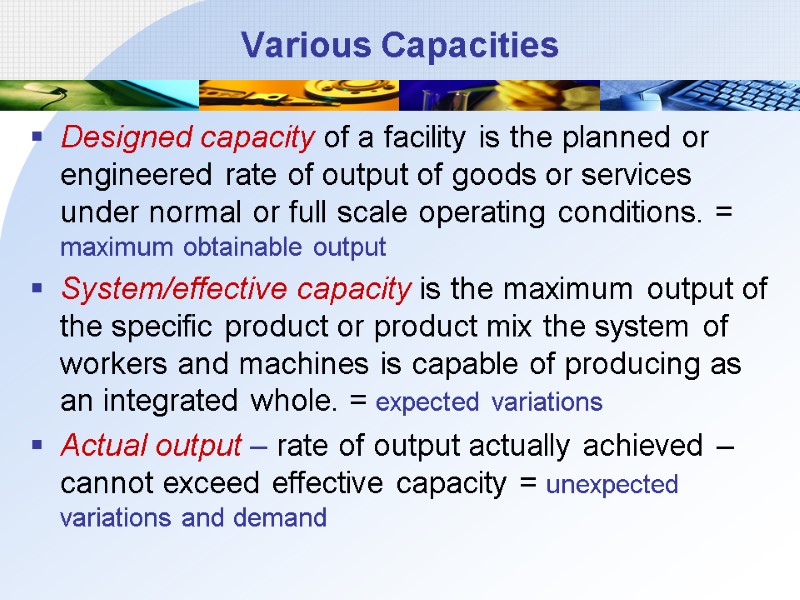

Various Capacities Designed capacity of a facility is the planned or engineered rate of output of goods or services under normal or full scale operating conditions. = maximum obtainable output System/effective capacity is the maximum output of the specific product or product mix the system of workers and machines is capable of producing as an integrated whole. = expected variations Actual output – rate of output actually achieved – cannot exceed effective capacity = unexpected variations and demand

Various Capacities Designed capacity of a facility is the planned or engineered rate of output of goods or services under normal or full scale operating conditions. = maximum obtainable output System/effective capacity is the maximum output of the specific product or product mix the system of workers and machines is capable of producing as an integrated whole. = expected variations Actual output – rate of output actually achieved – cannot exceed effective capacity = unexpected variations and demand

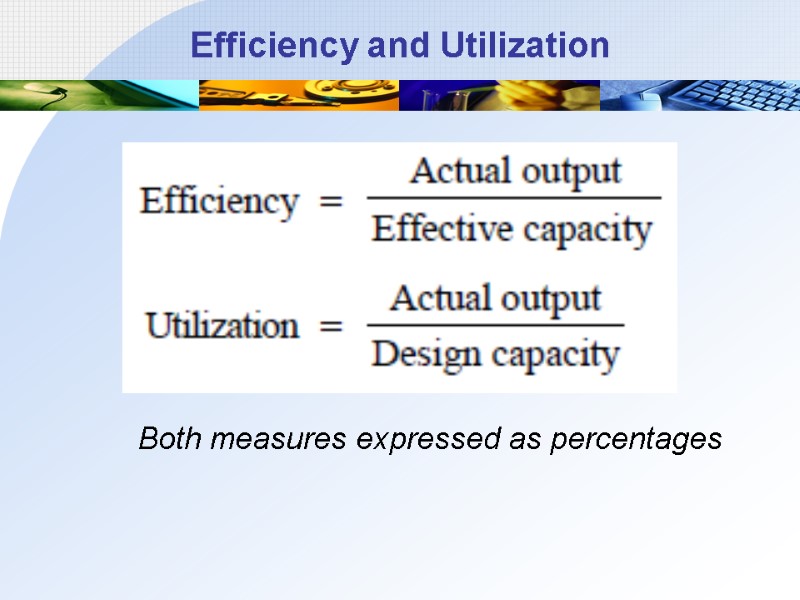

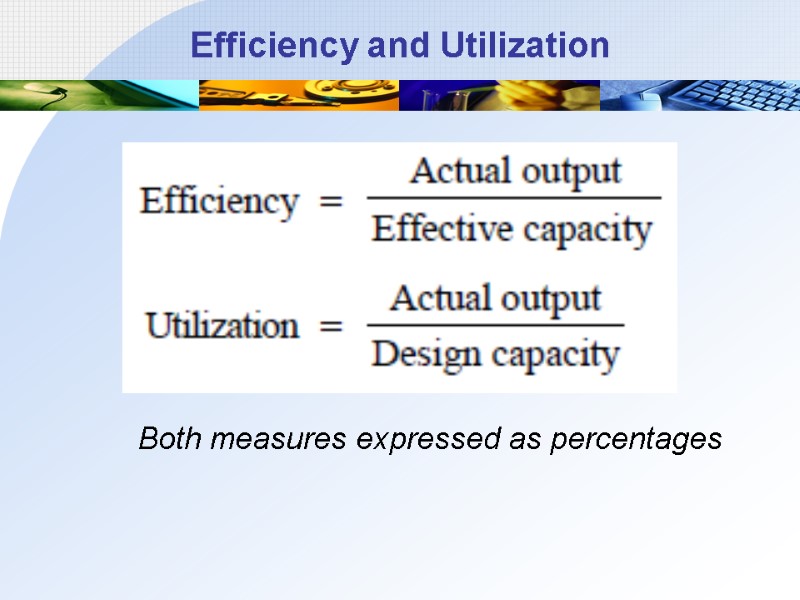

Efficiency and Utilization Both measures expressed as percentages

Efficiency and Utilization Both measures expressed as percentages

Determinants of Effective Capacity Facilities Product and service factors Process factors Human factors Operational factors Supply chain factors External factors

Determinants of Effective Capacity Facilities Product and service factors Process factors Human factors Operational factors Supply chain factors External factors

Capacity Management Goal The objective of capacity management (i.e. planning and control of capacity) is to match the level of operations to the level of demand.

Capacity Management Goal The objective of capacity management (i.e. planning and control of capacity) is to match the level of operations to the level of demand.

Capacity Planning Capacity planning is the process used to determine how much capacity is needed (and when) in order to manufacture greater product or begin production of a new product.

Capacity Planning Capacity planning is the process used to determine how much capacity is needed (and when) in order to manufacture greater product or begin production of a new product.

Three Steps for Capacity Planning Determine Service Level Requirements Analyze Current Capacity Planning for the future

Three Steps for Capacity Planning Determine Service Level Requirements Analyze Current Capacity Planning for the future

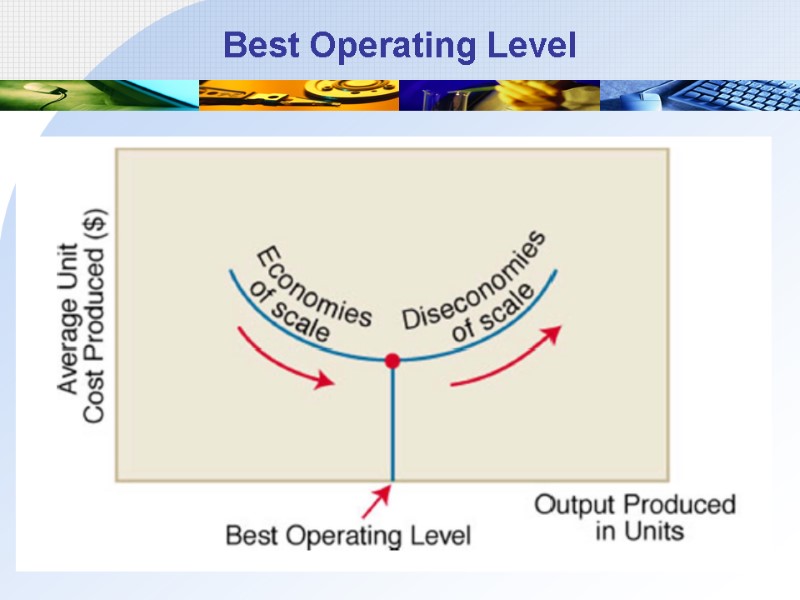

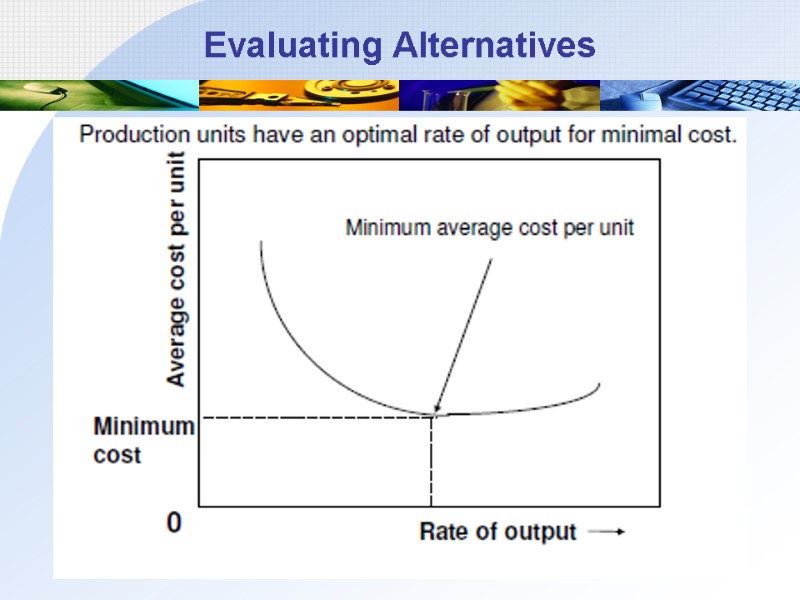

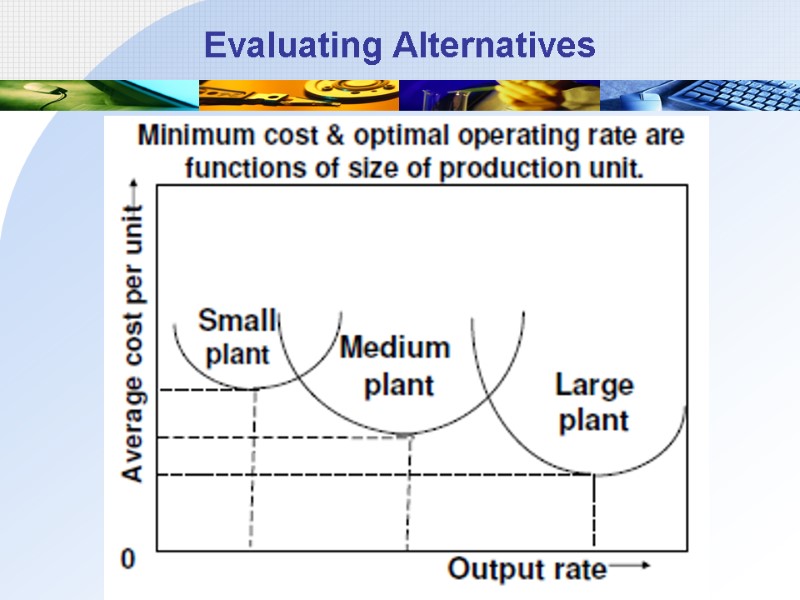

How Much Capacity Is Best? The Best Operating Level is the output than results in the lowest average unit cost Economies of Scale: – Where the cost per unit of output drops as volume of output increases – Spread the fixed costs of buildings & equipment over multiple units, allow bulk purchasing & handling of material Diseconomies of Scale: – Where the cost per unit rises as volume increases – Often caused by congestion (overwhelming the process with too much work-in-process) and scheduling complexity

How Much Capacity Is Best? The Best Operating Level is the output than results in the lowest average unit cost Economies of Scale: – Where the cost per unit of output drops as volume of output increases – Spread the fixed costs of buildings & equipment over multiple units, allow bulk purchasing & handling of material Diseconomies of Scale: – Where the cost per unit rises as volume increases – Often caused by congestion (overwhelming the process with too much work-in-process) and scheduling complexity

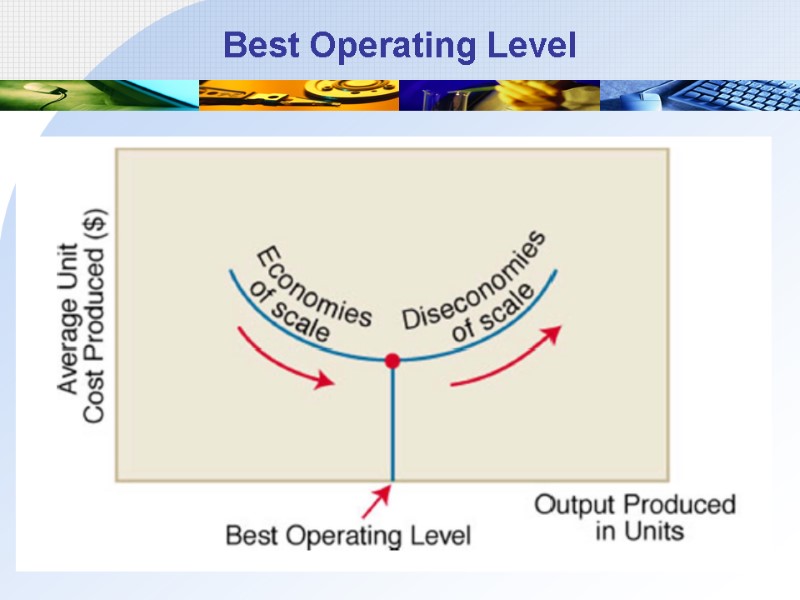

Best Operating Level

Best Operating Level

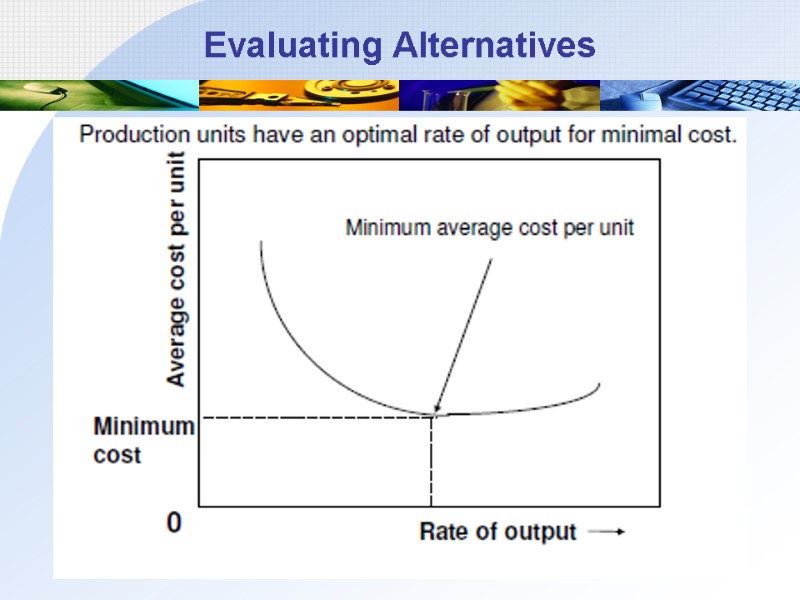

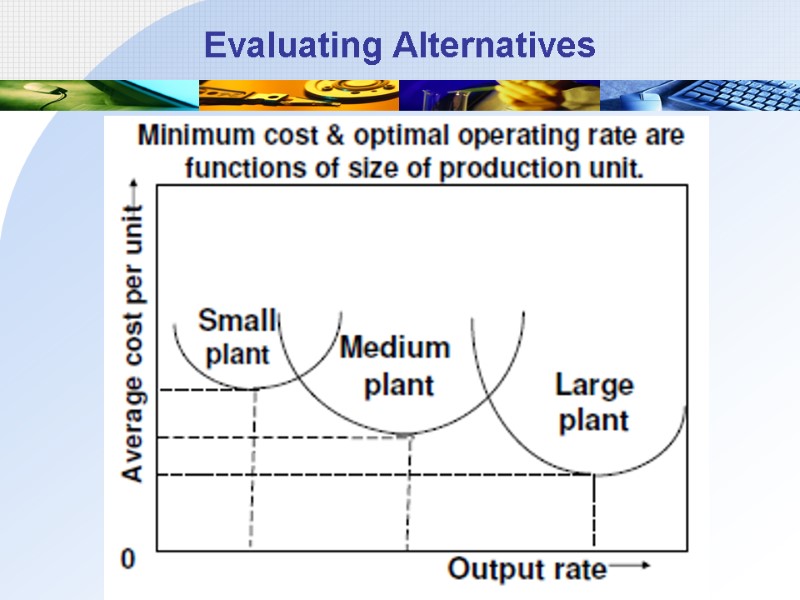

Evaluating Alternatives

Evaluating Alternatives

Evaluating Alternatives

Evaluating Alternatives

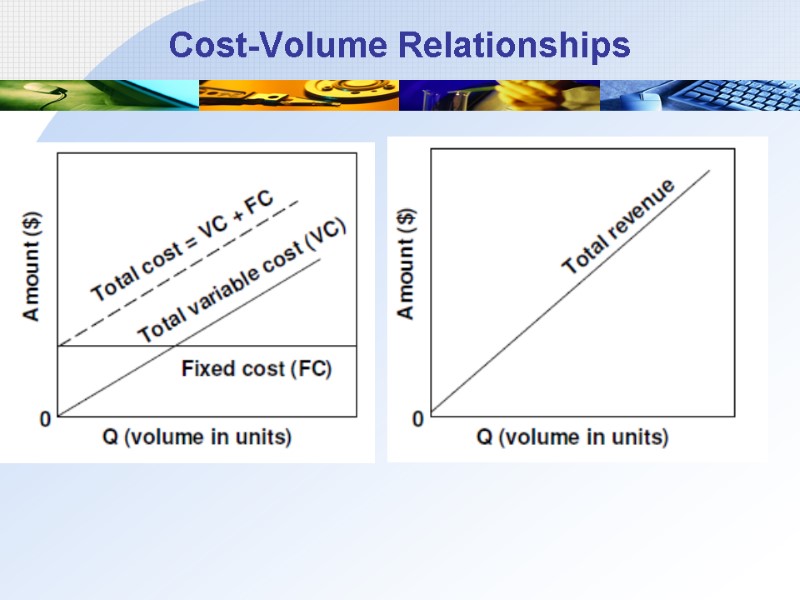

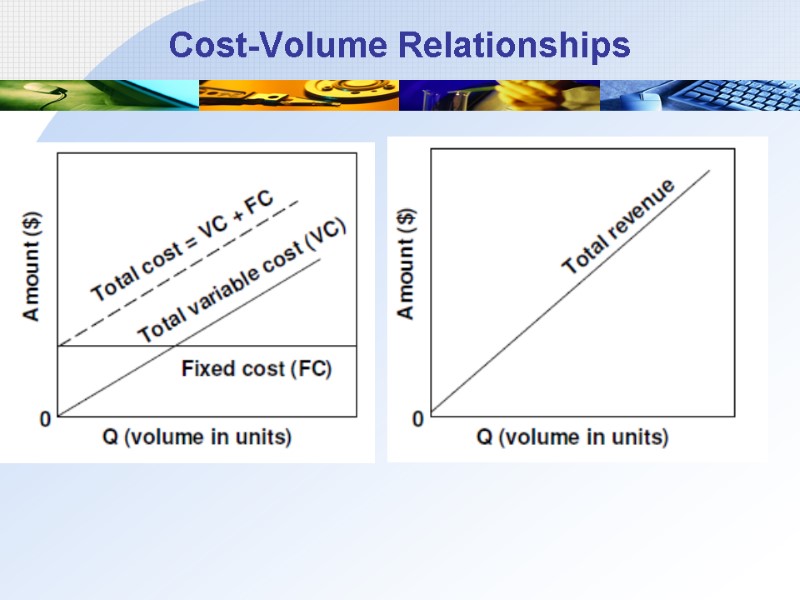

Cost-Volume Relationships

Cost-Volume Relationships

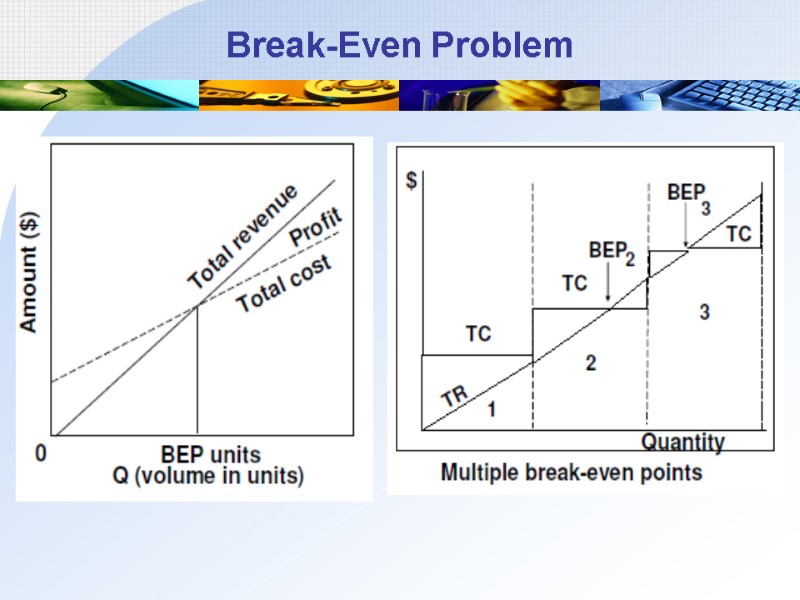

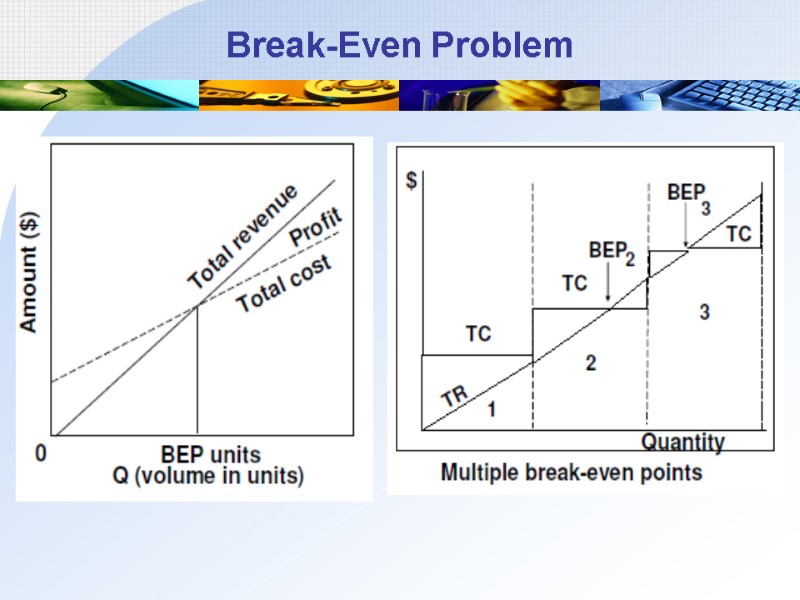

Break-Even Problem

Break-Even Problem

Assumptions of Cost-Volume Analysis One product is involved Everything produced can be sold Variable cost per unit is the same regardless of volume Fixed costs do not change with volume Revenue per unit constant with volume Revenue per unit exceeds variable cost per unit

Assumptions of Cost-Volume Analysis One product is involved Everything produced can be sold Variable cost per unit is the same regardless of volume Fixed costs do not change with volume Revenue per unit constant with volume Revenue per unit exceeds variable cost per unit

![>Evaluating Capacity Alternatives Cost-Volume Formulas TC=FC+(VCxQ) TR=RxQ P=TR–TC P=(RXQ)–[FC+(VCXQ)] Volume=(SP+FC)/(R-VC) QBEP=FC/(R-VC) >Evaluating Capacity Alternatives Cost-Volume Formulas TC=FC+(VCxQ) TR=RxQ P=TR–TC P=(RXQ)–[FC+(VCXQ)] Volume=(SP+FC)/(R-VC) QBEP=FC/(R-VC)](https://present5.com/presentacii-2/20171208\14394-topic_4_2.ppt\14394-topic_4_2_23.jpg) Evaluating Capacity Alternatives Cost-Volume Formulas TC=FC+(VCxQ) TR=RxQ P=TR–TC P=(RXQ)–[FC+(VCXQ)] Volume=(SP+FC)/(R-VC) QBEP=FC/(R-VC)

Evaluating Capacity Alternatives Cost-Volume Formulas TC=FC+(VCxQ) TR=RxQ P=TR–TC P=(RXQ)–[FC+(VCXQ)] Volume=(SP+FC)/(R-VC) QBEP=FC/(R-VC)

Process of Capacity Planning Capacity planning is concerned with defining the long-term and the short-term capacity needs of an organisation and determining how those needs will be satisfied. Capacity requirements can be evaluated from two perspectives—long-term capacity strategies and short-term capacity strategies.

Process of Capacity Planning Capacity planning is concerned with defining the long-term and the short-term capacity needs of an organisation and determining how those needs will be satisfied. Capacity requirements can be evaluated from two perspectives—long-term capacity strategies and short-term capacity strategies.

Long-term capacity strategies Long-term capacity requirements are: are more difficult to determine are dependent on marketing plans, product development and life-cycle of the product. is concerned with accommodating major changes that affect overall level of the output in long-term.

Long-term capacity strategies Long-term capacity requirements are: are more difficult to determine are dependent on marketing plans, product development and life-cycle of the product. is concerned with accommodating major changes that affect overall level of the output in long-term.

Long-range Capacity Decisions Multiple products: Company’s produce more than one product using the same facilities in order to increase the profit. Phasing in capacity: In high technology industries, and in industries where technology developments are very fast, the rate of obsolescence is high. The products should be brought into the market quickly. Phasing out capacity: The outdated manufacturing facilities cause excessive plant closures and down time.

Long-range Capacity Decisions Multiple products: Company’s produce more than one product using the same facilities in order to increase the profit. Phasing in capacity: In high technology industries, and in industries where technology developments are very fast, the rate of obsolescence is high. The products should be brought into the market quickly. Phasing out capacity: The outdated manufacturing facilities cause excessive plant closures and down time.

Short-term capacity strategies Managers looking ahead up to 12 months Fundamental capacity is fixed. Many short-term adjustments for increasing or decreasing capacity are possible Capital-intensive processes depend on physical facilities, plant and equipment. Short-term capacity can be modified by operating these facilities more or less intensively than normal

Short-term capacity strategies Managers looking ahead up to 12 months Fundamental capacity is fixed. Many short-term adjustments for increasing or decreasing capacity are possible Capital-intensive processes depend on physical facilities, plant and equipment. Short-term capacity can be modified by operating these facilities more or less intensively than normal

Types of Short-term Capacity Strategies Inventories: Stock finished goods during slack periods to meet the demand during peak period. Backlog: During peak periods, the willing customers are requested to wait and their orders are fulfilled after a peak demand period. Employment level (hiring or firing): Hire additional employees during peak demand period and layoff employees as demand decreases. Employee training: Develop multi skilled employees through training so that they can be rotated among different jobs. The multi skilling helps as an alternative to hiring employees. Subcontracting: During peak periods, hire the capacity of other firms temporarily to make the component parts or products. Process design: Change job contents by redesigning the job.

Types of Short-term Capacity Strategies Inventories: Stock finished goods during slack periods to meet the demand during peak period. Backlog: During peak periods, the willing customers are requested to wait and their orders are fulfilled after a peak demand period. Employment level (hiring or firing): Hire additional employees during peak demand period and layoff employees as demand decreases. Employee training: Develop multi skilled employees through training so that they can be rotated among different jobs. The multi skilling helps as an alternative to hiring employees. Subcontracting: During peak periods, hire the capacity of other firms temporarily to make the component parts or products. Process design: Change job contents by redesigning the job.

Thank You !

Thank You !