Lecture: Supply Chain Supply-Chain Management Measuring Supply-Chain Performance

8998-supply_chain.ppt

- Количество слайдов: 49

Lecture: Supply Chain

Lecture: Supply Chain

Supply-Chain Management Measuring Supply-Chain Performance Supply Chain Decisions Cycle and Push-Pull View of Supply Chains Bullwhip Effect Outsourcing Value Density Mass Customization OBJECTIVES 10-2

Supply-Chain Management Measuring Supply-Chain Performance Supply Chain Decisions Cycle and Push-Pull View of Supply Chains Bullwhip Effect Outsourcing Value Density Mass Customization OBJECTIVES 10-2

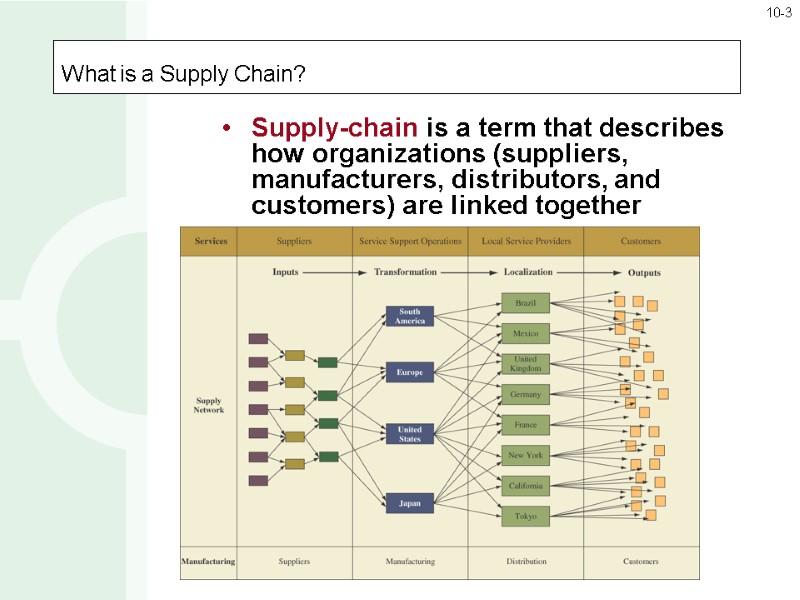

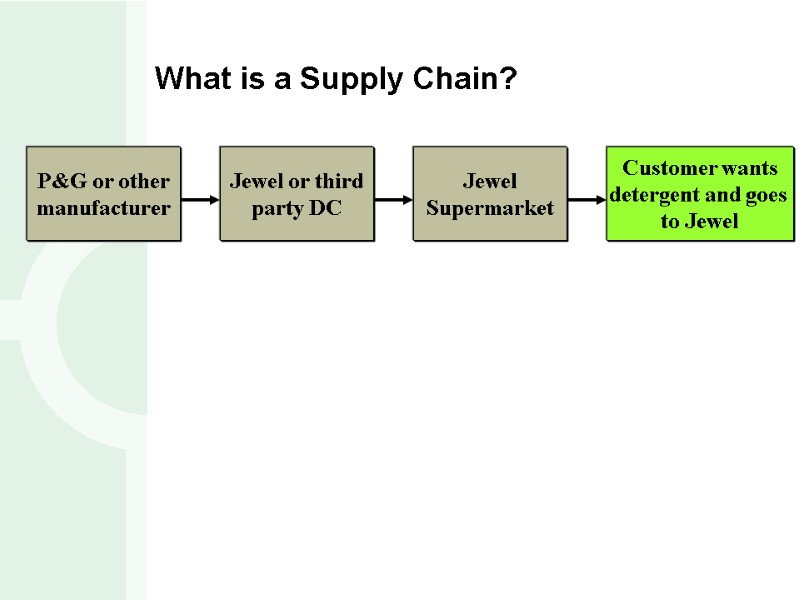

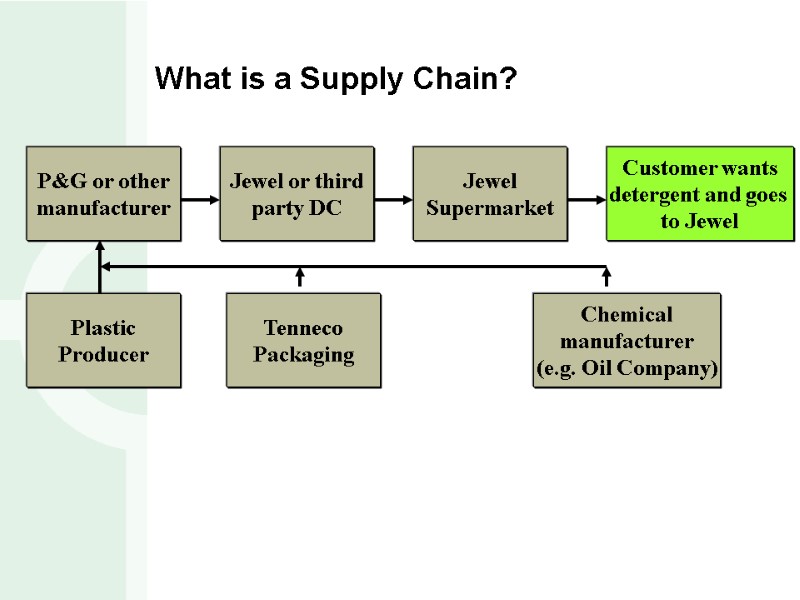

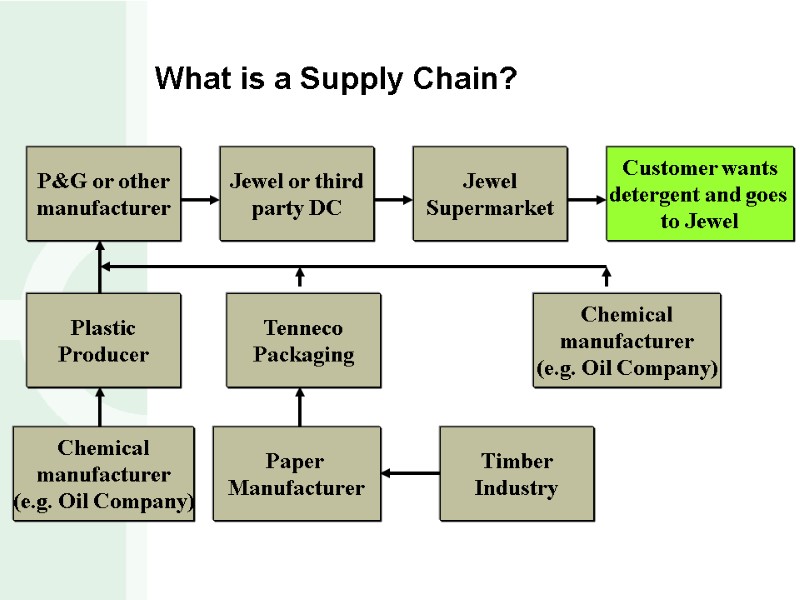

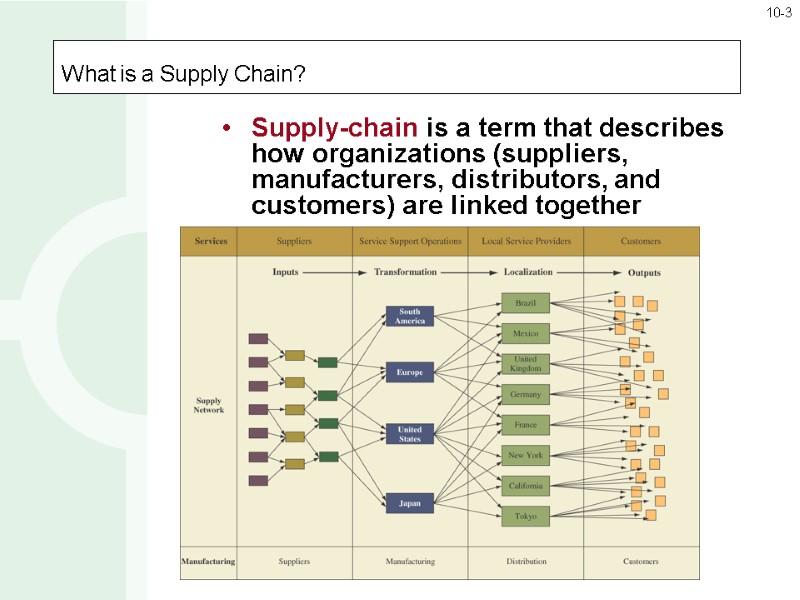

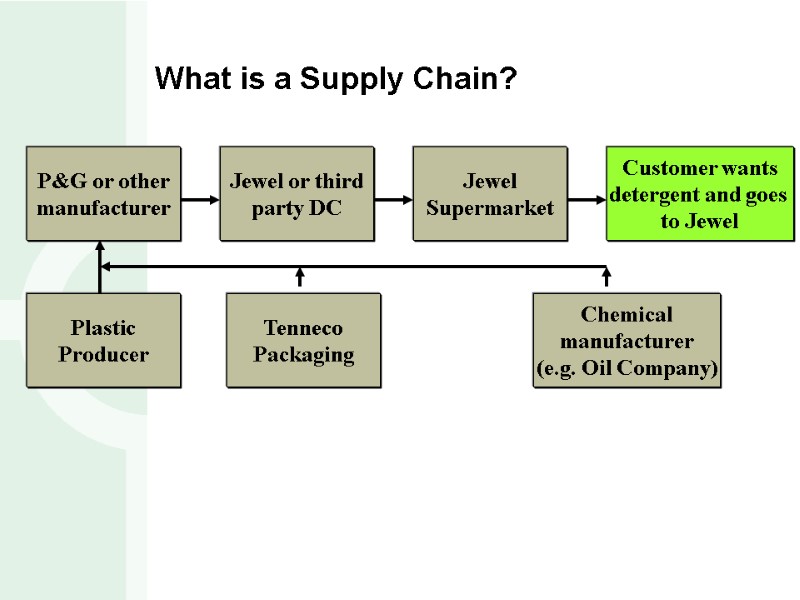

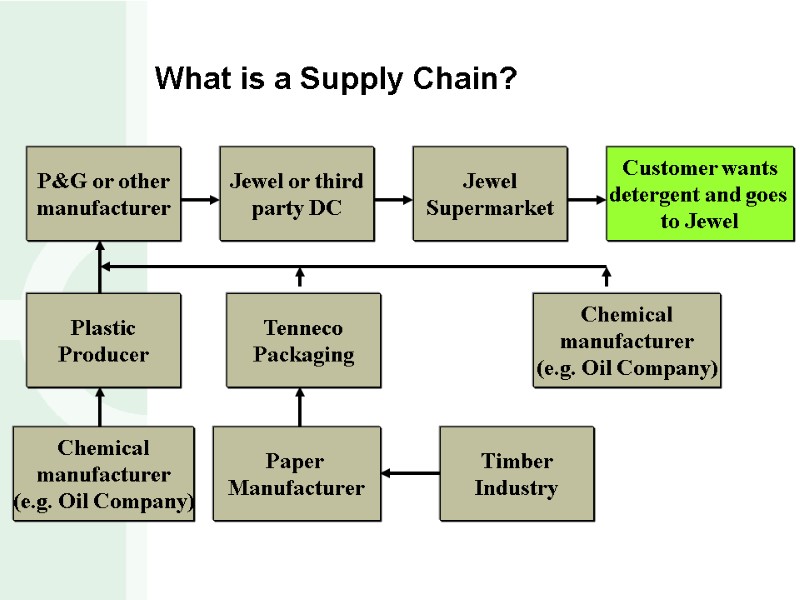

Supply-chain is a term that describes how organizations (suppliers, manufacturers, distributors, and customers) are linked together What is a Supply Chain? 10-3

Supply-chain is a term that describes how organizations (suppliers, manufacturers, distributors, and customers) are linked together What is a Supply Chain? 10-3

What is Supply Chain Management? Supply-chain management is a total system approach to managing the entire flow of information, materials, and services from raw-material suppliers through factories and warehouses to the end customer 10-4

What is Supply Chain Management? Supply-chain management is a total system approach to managing the entire flow of information, materials, and services from raw-material suppliers through factories and warehouses to the end customer 10-4

What is a Supply Chain? Customer wants detergent and goes to Jewel Jewel Supermarket Jewel or third party DC P&G or other manufacturer

What is a Supply Chain? Customer wants detergent and goes to Jewel Jewel Supermarket Jewel or third party DC P&G or other manufacturer

What is a Supply Chain? Customer wants detergent and goes to Jewel Jewel Supermarket Jewel or third party DC P&G or other manufacturer Plastic Producer Tenneco Packaging Chemical manufacturer (e.g. Oil Company)

What is a Supply Chain? Customer wants detergent and goes to Jewel Jewel Supermarket Jewel or third party DC P&G or other manufacturer Plastic Producer Tenneco Packaging Chemical manufacturer (e.g. Oil Company)

What is a Supply Chain? Customer wants detergent and goes to Jewel Jewel Supermarket Jewel or third party DC P&G or other manufacturer Plastic Producer Chemical manufacturer (e.g. Oil Company) Tenneco Packaging Paper Manufacturer Timber Industry Chemical manufacturer (e.g. Oil Company)

What is a Supply Chain? Customer wants detergent and goes to Jewel Jewel Supermarket Jewel or third party DC P&G or other manufacturer Plastic Producer Chemical manufacturer (e.g. Oil Company) Tenneco Packaging Paper Manufacturer Timber Industry Chemical manufacturer (e.g. Oil Company)

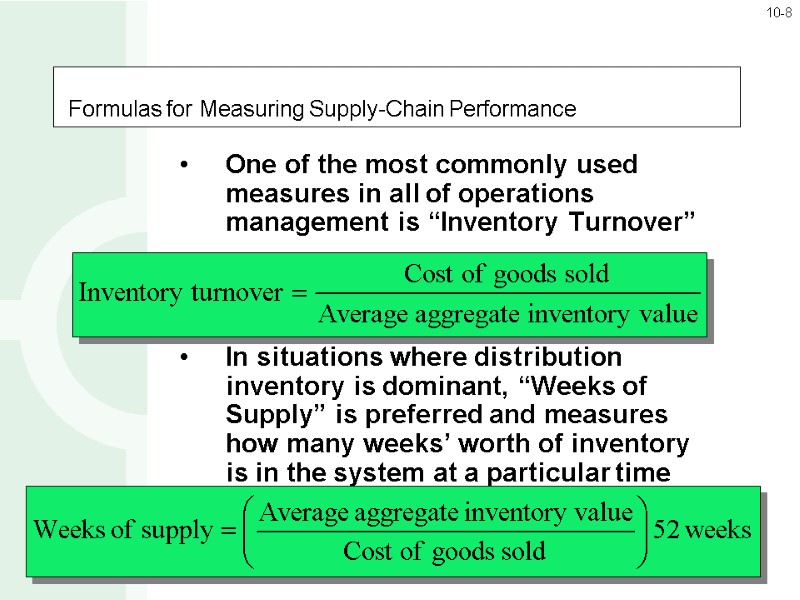

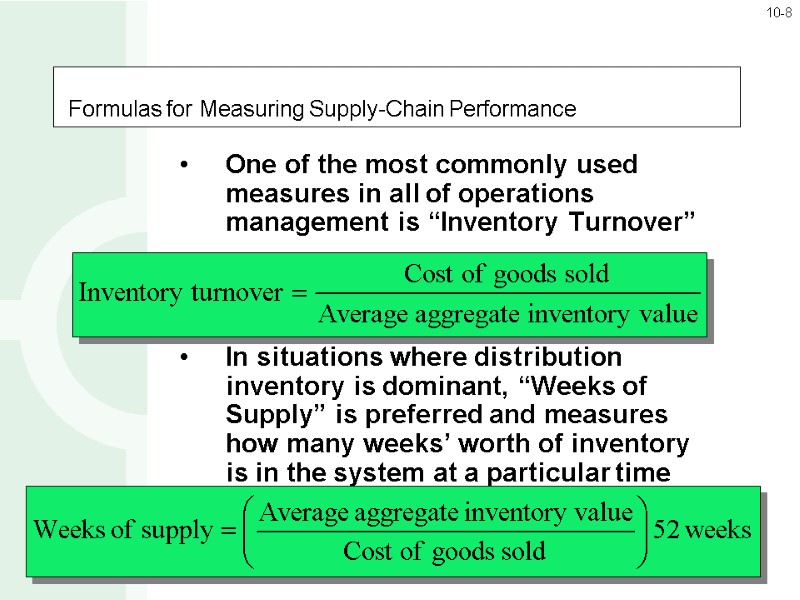

Formulas for Measuring Supply-Chain Performance One of the most commonly used measures in all of operations management is “Inventory Turnover” In situations where distribution inventory is dominant, “Weeks of Supply” is preferred and measures how many weeks’ worth of inventory is in the system at a particular time 10-8

Formulas for Measuring Supply-Chain Performance One of the most commonly used measures in all of operations management is “Inventory Turnover” In situations where distribution inventory is dominant, “Weeks of Supply” is preferred and measures how many weeks’ worth of inventory is in the system at a particular time 10-8

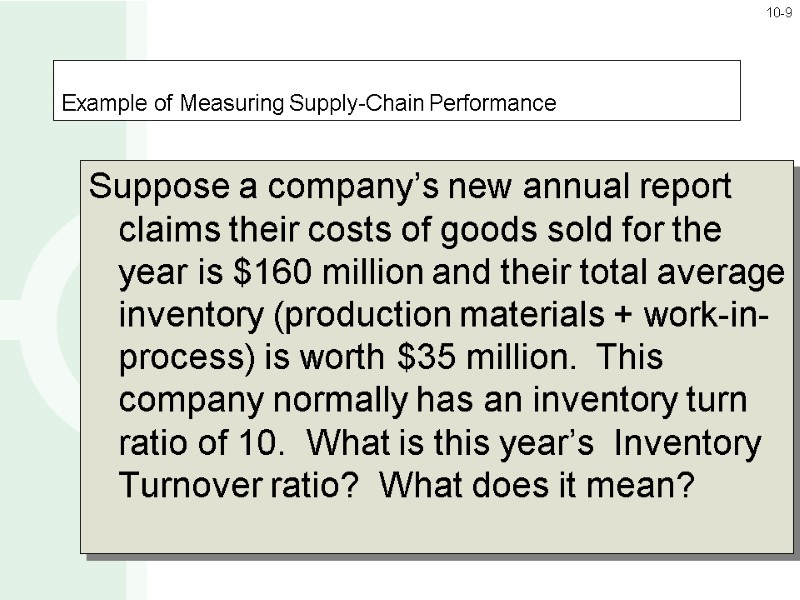

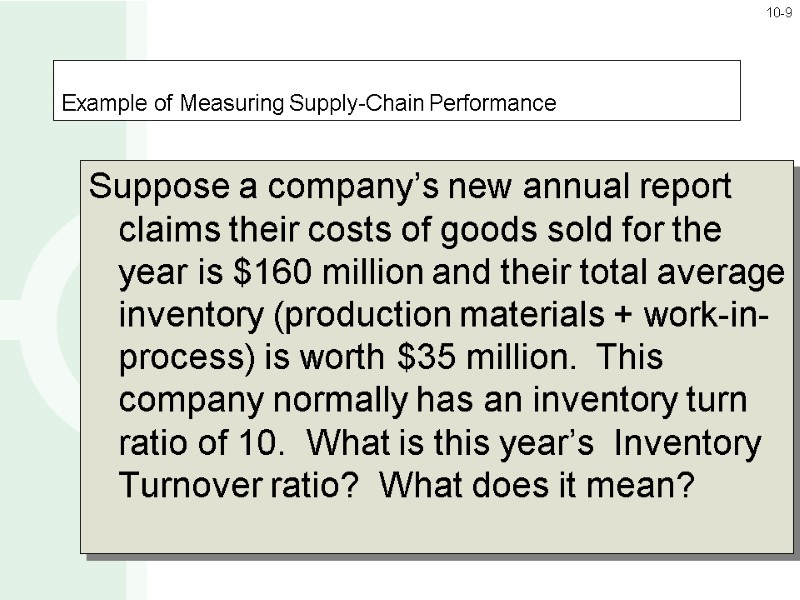

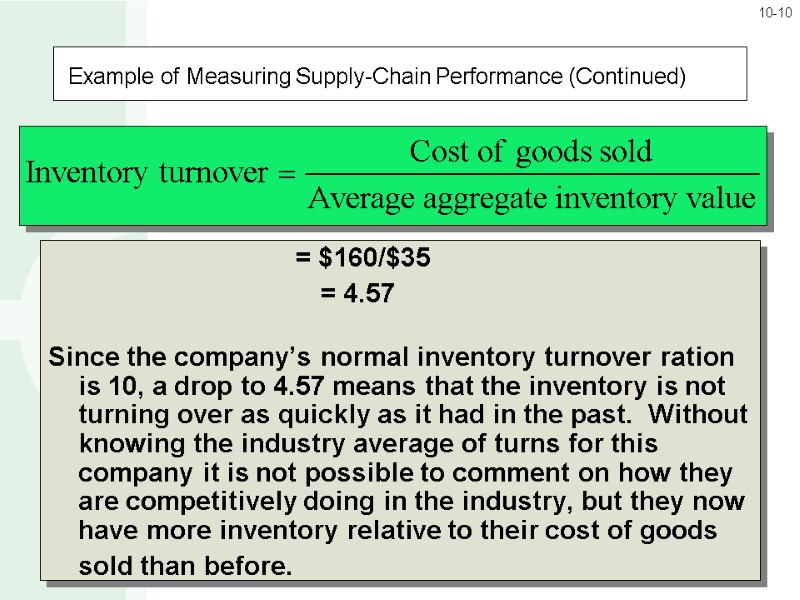

Example of Measuring Supply-Chain Performance Suppose a company’s new annual report claims their costs of goods sold for the year is $160 million and their total average inventory (production materials + work-in-process) is worth $35 million. This company normally has an inventory turn ratio of 10. What is this year’s Inventory Turnover ratio? What does it mean? 10-9

Example of Measuring Supply-Chain Performance Suppose a company’s new annual report claims their costs of goods sold for the year is $160 million and their total average inventory (production materials + work-in-process) is worth $35 million. This company normally has an inventory turn ratio of 10. What is this year’s Inventory Turnover ratio? What does it mean? 10-9

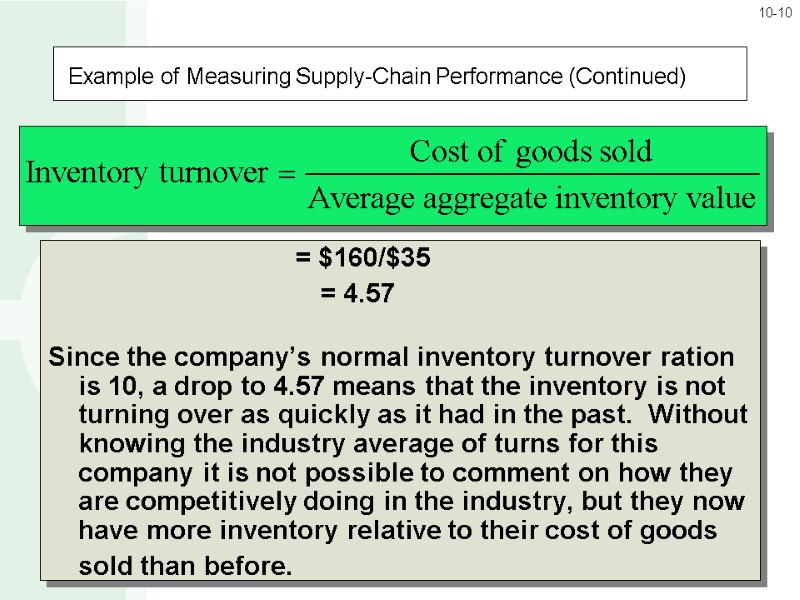

Example of Measuring Supply-Chain Performance (Continued) = $160/$35 = 4.57 Since the company’s normal inventory turnover ration is 10, a drop to 4.57 means that the inventory is not turning over as quickly as it had in the past. Without knowing the industry average of turns for this company it is not possible to comment on how they are competitively doing in the industry, but they now have more inventory relative to their cost of goods sold than before. 10-10

Example of Measuring Supply-Chain Performance (Continued) = $160/$35 = 4.57 Since the company’s normal inventory turnover ration is 10, a drop to 4.57 means that the inventory is not turning over as quickly as it had in the past. Without knowing the industry average of turns for this company it is not possible to comment on how they are competitively doing in the industry, but they now have more inventory relative to their cost of goods sold than before. 10-10

Decision Phases of a Supply Chain Supply chain strategy or design Supply chain planning Supply chain operation

Decision Phases of a Supply Chain Supply chain strategy or design Supply chain planning Supply chain operation

Supply Chain Strategy or Design Decisions about the structure of the supply chain and what processes each stage will perform What are some strategic supply chain decisions? Locations and capacities of facilities Products to be made or stored at various locations Modes of transportation Information systems Chain design must support strategic objectives Design decisions are long-term and expensive to reverse – must address market uncertainty

Supply Chain Strategy or Design Decisions about the structure of the supply chain and what processes each stage will perform What are some strategic supply chain decisions? Locations and capacities of facilities Products to be made or stored at various locations Modes of transportation Information systems Chain design must support strategic objectives Design decisions are long-term and expensive to reverse – must address market uncertainty

Supply Chain Planning Definition of a set of policies that govern short-term operations Fixed by the supply configuration from previous phase Starts with a forecast of demand in the coming year

Supply Chain Planning Definition of a set of policies that govern short-term operations Fixed by the supply configuration from previous phase Starts with a forecast of demand in the coming year

Supply Chain Planning What are some planning decisions? Which markets will be supplied from which locations Planned buildup of inventories Subcontracting, backup locations Inventory policies Timing and size of market promotions Must consider in planning decisions demand uncertainty, exchange rates, competition over the time horizon

Supply Chain Planning What are some planning decisions? Which markets will be supplied from which locations Planned buildup of inventories Subcontracting, backup locations Inventory policies Timing and size of market promotions Must consider in planning decisions demand uncertainty, exchange rates, competition over the time horizon

Supply Chain Operation Time horizon is weekly or daily Decisions regarding individual customer orders Supply chain configuration is fixed and operating policies are determined Goal is to implement the operating policies as effectively as possible – some examples? Allocate orders to inventory or production, set order due dates, generate pick lists at a warehouse, allocate an order to a particular shipment, set delivery schedules, place replenishment orders Much less uncertainty (short time horizon)

Supply Chain Operation Time horizon is weekly or daily Decisions regarding individual customer orders Supply chain configuration is fixed and operating policies are determined Goal is to implement the operating policies as effectively as possible – some examples? Allocate orders to inventory or production, set order due dates, generate pick lists at a warehouse, allocate an order to a particular shipment, set delivery schedules, place replenishment orders Much less uncertainty (short time horizon)

Process View of a Supply Chain Cycle view: processes in a supply chain are divided into a series of cycles, each performed at the interfaces between two successive supply chain stages Push/pull view: processes in a supply chain are divided into two categories: Executed in response to a customer order (pull) Executed in anticipation of a customer order (push)

Process View of a Supply Chain Cycle view: processes in a supply chain are divided into a series of cycles, each performed at the interfaces between two successive supply chain stages Push/pull view: processes in a supply chain are divided into two categories: Executed in response to a customer order (pull) Executed in anticipation of a customer order (push)

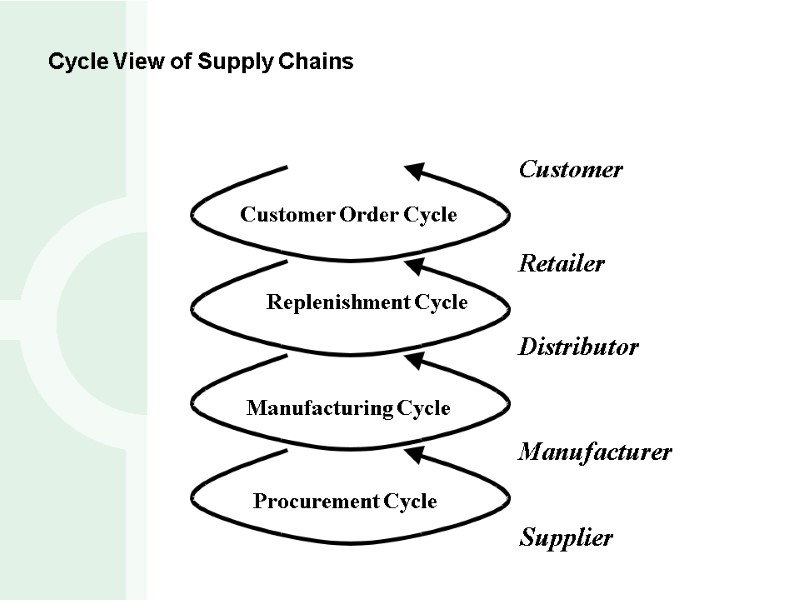

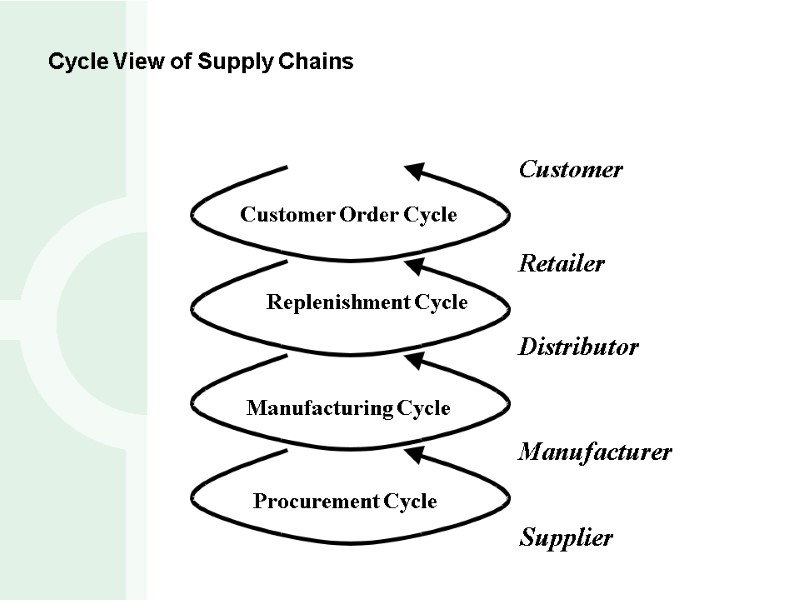

Cycle View of Supply Chains Customer Order Cycle Replenishment Cycle Manufacturing Cycle Procurement Cycle Customer Retailer Distributor Manufacturer Supplier

Cycle View of Supply Chains Customer Order Cycle Replenishment Cycle Manufacturing Cycle Procurement Cycle Customer Retailer Distributor Manufacturer Supplier

Cycle View of a Supply Chain Each cycle occurs at the interface between two successive stages Customer order cycle (customer-retailer) Replenishment cycle (retailer-distributor) Manufacturing cycle (distributor-manufacturer) Procurement cycle (manufacturer-supplier) Cycle view clearly defines processes involved and the owners of each process. Specifies the roles and responsibilities of each member and the desired outcome of each process.

Cycle View of a Supply Chain Each cycle occurs at the interface between two successive stages Customer order cycle (customer-retailer) Replenishment cycle (retailer-distributor) Manufacturing cycle (distributor-manufacturer) Procurement cycle (manufacturer-supplier) Cycle view clearly defines processes involved and the owners of each process. Specifies the roles and responsibilities of each member and the desired outcome of each process.

Customer Order Cycle Involves all processes directly involved in receiving and filling the customer’s order Customer arrival Customer order entry Customer order fulfillment Customer order receiving

Customer Order Cycle Involves all processes directly involved in receiving and filling the customer’s order Customer arrival Customer order entry Customer order fulfillment Customer order receiving

Replenishment Cycle All processes involved in replenishing retailer inventories (retailer is now the customer) Retail order trigger Retail order entry Retail order fulfillment Retail order receiving

Replenishment Cycle All processes involved in replenishing retailer inventories (retailer is now the customer) Retail order trigger Retail order entry Retail order fulfillment Retail order receiving

Manufacturing Cycle All processes involved in replenishing distributor (or retailer) inventory Order arrival from the distributor, retailer, or customer Production scheduling Manufacturing and shipping Receiving at the distributor, retailer, or customer

Manufacturing Cycle All processes involved in replenishing distributor (or retailer) inventory Order arrival from the distributor, retailer, or customer Production scheduling Manufacturing and shipping Receiving at the distributor, retailer, or customer

Procurement Cycle All processes necessary to ensure that materials are available for manufacturing to occur according to schedule Manufacturer orders components from suppliers to replenish component inventories However, component orders can be determined precisely from production schedules (different from retailer/distributor orders that are based on uncertain customer demand) Important that suppliers be linked to the manufacturer’s production schedule

Procurement Cycle All processes necessary to ensure that materials are available for manufacturing to occur according to schedule Manufacturer orders components from suppliers to replenish component inventories However, component orders can be determined precisely from production schedules (different from retailer/distributor orders that are based on uncertain customer demand) Important that suppliers be linked to the manufacturer’s production schedule

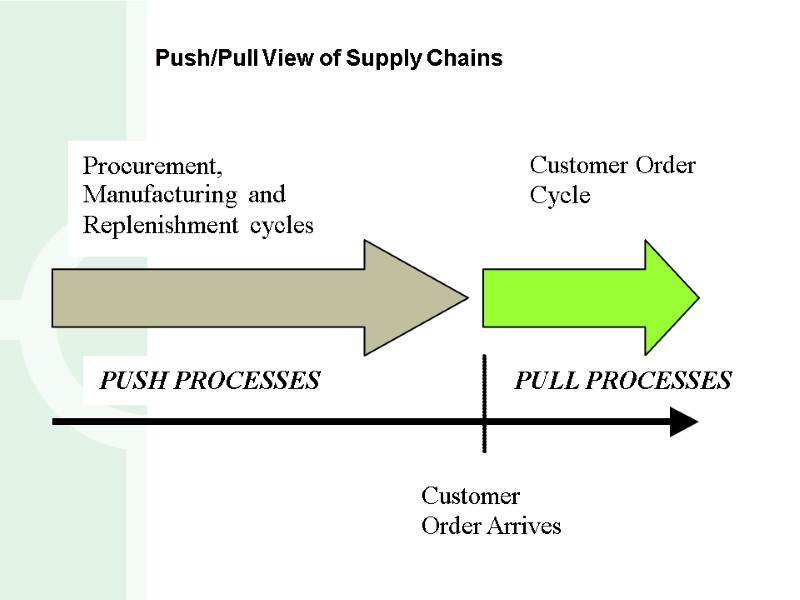

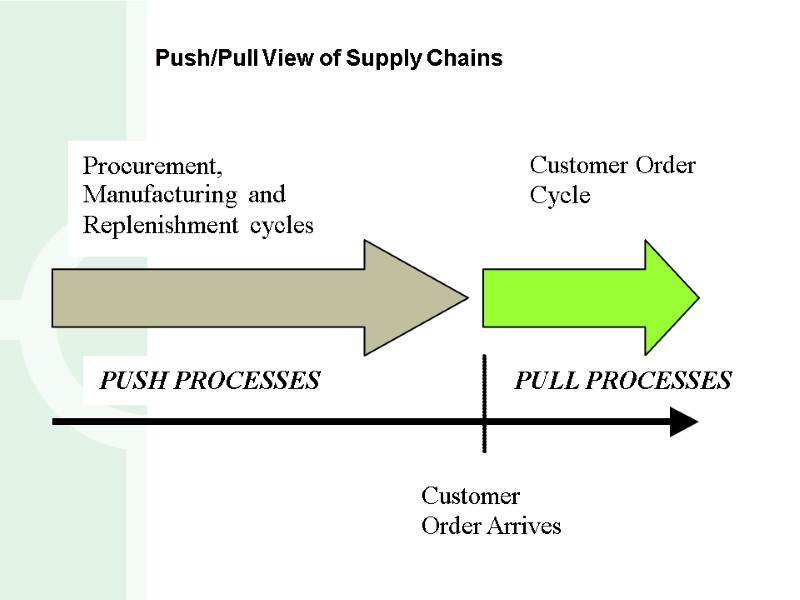

Push/Pull View of Supply Chains Procurement, Manufacturing and Replenishment cycles Customer Order Cycle Customer Order Arrives PUSH PROCESSES PULL PROCESSES

Push/Pull View of Supply Chains Procurement, Manufacturing and Replenishment cycles Customer Order Cycle Customer Order Arrives PUSH PROCESSES PULL PROCESSES

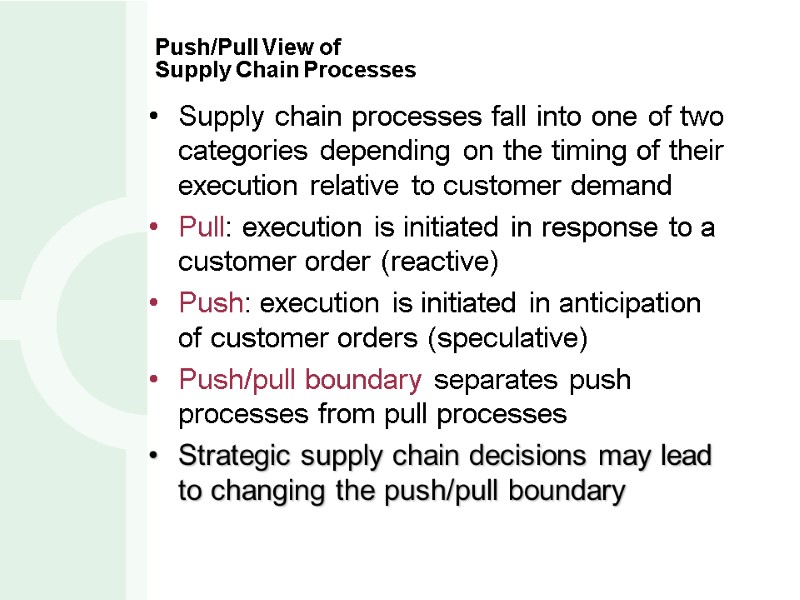

Push/Pull View of Supply Chain Processes Supply chain processes fall into one of two categories depending on the timing of their execution relative to customer demand Pull: execution is initiated in response to a customer order (reactive) Push: execution is initiated in anticipation of customer orders (speculative) Push/pull boundary separates push processes from pull processes Strategic supply chain decisions may lead to changing the push/pull boundary

Push/Pull View of Supply Chain Processes Supply chain processes fall into one of two categories depending on the timing of their execution relative to customer demand Pull: execution is initiated in response to a customer order (reactive) Push: execution is initiated in anticipation of customer orders (speculative) Push/pull boundary separates push processes from pull processes Strategic supply chain decisions may lead to changing the push/pull boundary

Example: L.L. Bean Where is the push/pull boundary for L.L. Bean? Customer order cycle is pull, remaining processes are push What are the implications of moving the boundary to the replenishment cycle?

Example: L.L. Bean Where is the push/pull boundary for L.L. Bean? Customer order cycle is pull, remaining processes are push What are the implications of moving the boundary to the replenishment cycle?

Example: Dell Where is the push/pull boundary for Dell? Customer and manufacturing is a pull cycle Procurement is a push cycle What are the implications of moving the boundary to the customer cycle?

Example: Dell Where is the push/pull boundary for Dell? Customer and manufacturing is a pull cycle Procurement is a push cycle What are the implications of moving the boundary to the customer cycle?

L.L. Bean vs. Dell Computer How would you compare the two cycles? Dell has fewer stages (customer, manufacturer, supplier) and more pull processes than L.L. Bean Can these differences affect supply chain performance? For Dell, no FG inventory, very low component inventory, supplier integration (demand info, part quality), faster new product introduction, outsources service/support (better coord.), close tracking of cash flows

L.L. Bean vs. Dell Computer How would you compare the two cycles? Dell has fewer stages (customer, manufacturer, supplier) and more pull processes than L.L. Bean Can these differences affect supply chain performance? For Dell, no FG inventory, very low component inventory, supplier integration (demand info, part quality), faster new product introduction, outsources service/support (better coord.), close tracking of cash flows

Example: Snapple Acquisition Quaker owns Gatorade and acquired Snapple in 1994 and tried to synergize the two distribution systems Snapple produced under contract, sold through restaurants, strong in northeast and west coast Gatorade manufactured by Quaker’s plants, sold in supermarkets and grocery stores, strong in south and southwest Efforts to merge supply chains failed, and in 28 months Quaker sold Snapple for 20% less than purchase price

Example: Snapple Acquisition Quaker owns Gatorade and acquired Snapple in 1994 and tried to synergize the two distribution systems Snapple produced under contract, sold through restaurants, strong in northeast and west coast Gatorade manufactured by Quaker’s plants, sold in supermarkets and grocery stores, strong in south and southwest Efforts to merge supply chains failed, and in 28 months Quaker sold Snapple for 20% less than purchase price

The Importance of Supply Chain Flows Close connection between design and management of supply chain flows (product, information, and cash) and supply chain success Dell: success Quaker Oats (Snapple): failure Supply chain decisions can play a significant role in the success or failure of a firm

The Importance of Supply Chain Flows Close connection between design and management of supply chain flows (product, information, and cash) and supply chain success Dell: success Quaker Oats (Snapple): failure Supply chain decisions can play a significant role in the success or failure of a firm

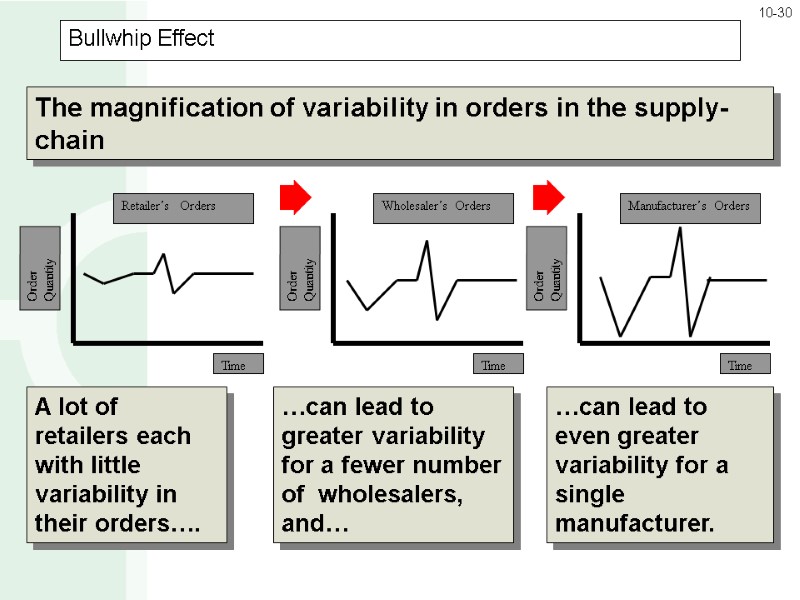

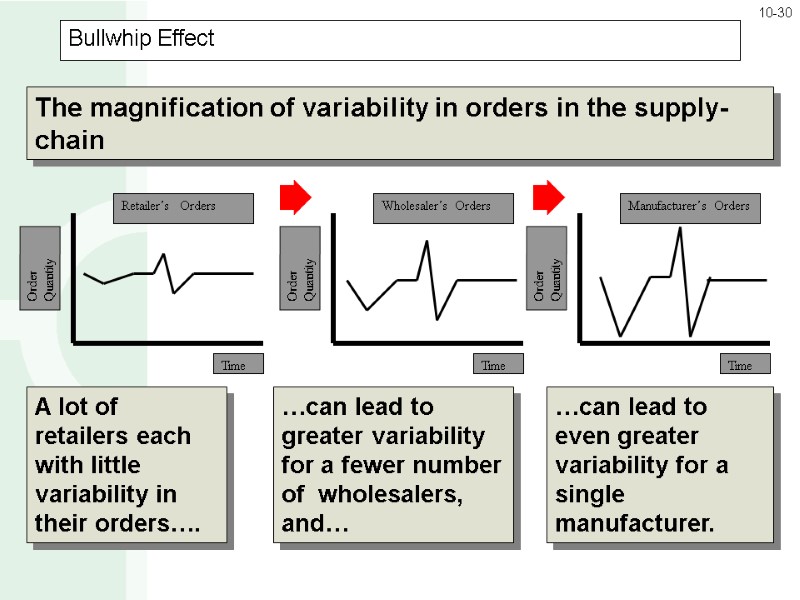

Bullwhip Effect Order Quantity Time Retailer’s Orders Order Quantity Time Wholesaler’s Orders Order Quantity Time Manufacturer’s Orders The magnification of variability in orders in the supply-chain A lot of retailers each with little variability in their orders…. …can lead to greater variability for a fewer number of wholesalers, and… …can lead to even greater variability for a single manufacturer. 10-30

Bullwhip Effect Order Quantity Time Retailer’s Orders Order Quantity Time Wholesaler’s Orders Order Quantity Time Manufacturer’s Orders The magnification of variability in orders in the supply-chain A lot of retailers each with little variability in their orders…. …can lead to greater variability for a fewer number of wholesalers, and… …can lead to even greater variability for a single manufacturer. 10-30

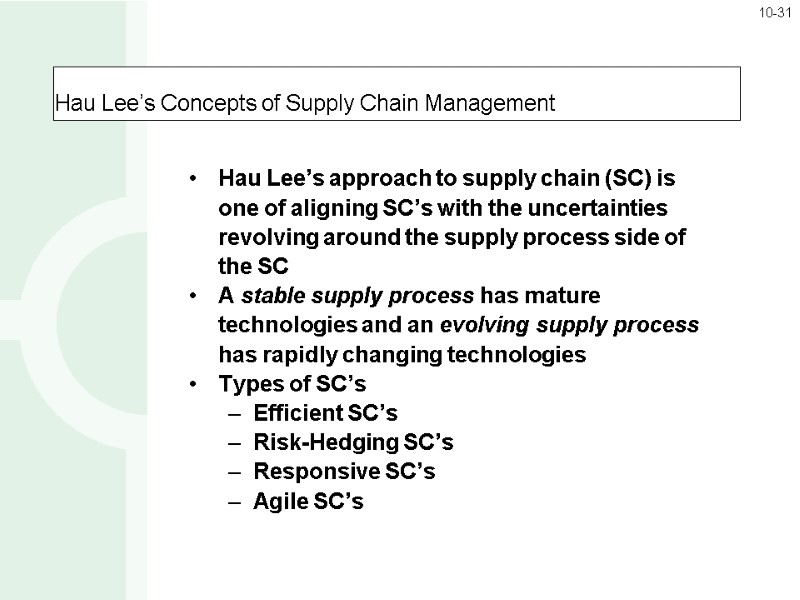

Hau Lee’s Concepts of Supply Chain Management Hau Lee’s approach to supply chain (SC) is one of aligning SC’s with the uncertainties revolving around the supply process side of the SC A stable supply process has mature technologies and an evolving supply process has rapidly changing technologies Types of SC’s Efficient SC’s Risk-Hedging SC’s Responsive SC’s Agile SC’s 10-31

Hau Lee’s Concepts of Supply Chain Management Hau Lee’s approach to supply chain (SC) is one of aligning SC’s with the uncertainties revolving around the supply process side of the SC A stable supply process has mature technologies and an evolving supply process has rapidly changing technologies Types of SC’s Efficient SC’s Risk-Hedging SC’s Responsive SC’s Agile SC’s 10-31

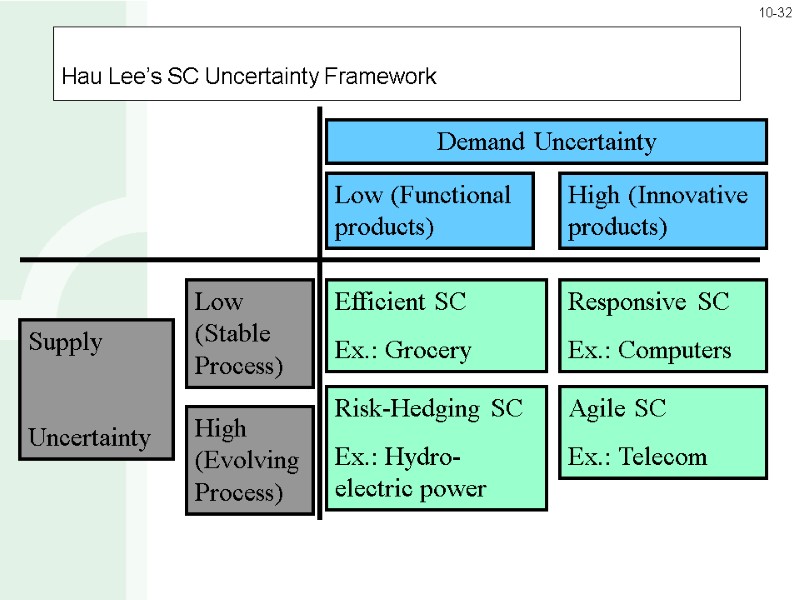

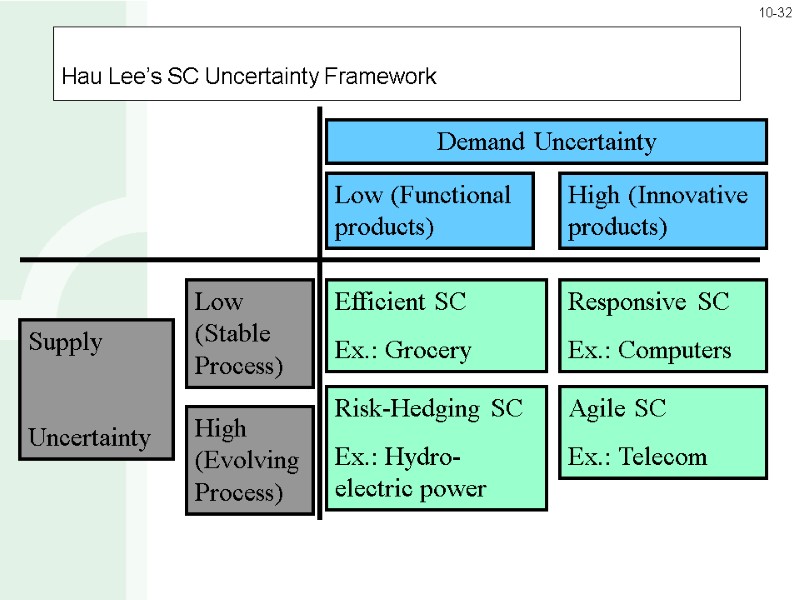

Hau Lee’s SC Uncertainty Framework Efficient SC Ex.: Grocery Responsive SC Ex.: Computers Risk-Hedging SC Ex.: Hydro-electric power Agile SC Ex.: Telecom 10-32

Hau Lee’s SC Uncertainty Framework Efficient SC Ex.: Grocery Responsive SC Ex.: Computers Risk-Hedging SC Ex.: Hydro-electric power Agile SC Ex.: Telecom 10-32

Types of Supply Chain Strategies Efficient – highest cost efficiency Risk-hedging – pool and share resources so that risks in supply disruption can be shared Responsive – be responsive and flexible to customer needs Agile – be responsive and flexible to customers, hedge risks of supply shortages

Types of Supply Chain Strategies Efficient – highest cost efficiency Risk-hedging – pool and share resources so that risks in supply disruption can be shared Responsive – be responsive and flexible to customer needs Agile – be responsive and flexible to customers, hedge risks of supply shortages

What is Outsourcing? Outsourcing is defined as the act of moving a firm’s internal activities and decision responsibility to outside providers 10-34

What is Outsourcing? Outsourcing is defined as the act of moving a firm’s internal activities and decision responsibility to outside providers 10-34

Reasons to Outsource Organizationally-driven Improvement-driven Financially-driven Revenue-driven Cost-driven Employee-driven 10-35

Reasons to Outsource Organizationally-driven Improvement-driven Financially-driven Revenue-driven Cost-driven Employee-driven 10-35

Value Density Value density is defined as the value of an item per pound of weight It is used as an important measure when deciding where items should be stocked geographically and how they should be shipped 10-37

Value Density Value density is defined as the value of an item per pound of weight It is used as an important measure when deciding where items should be stocked geographically and how they should be shipped 10-37

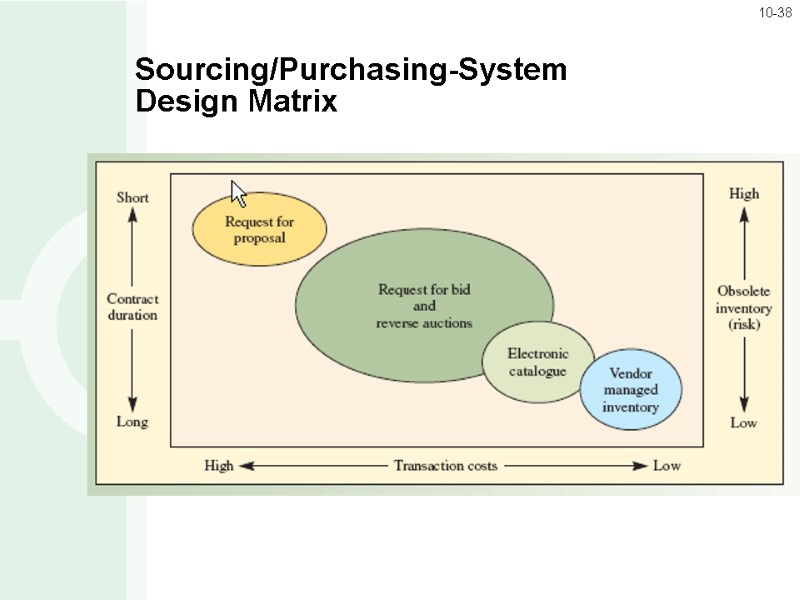

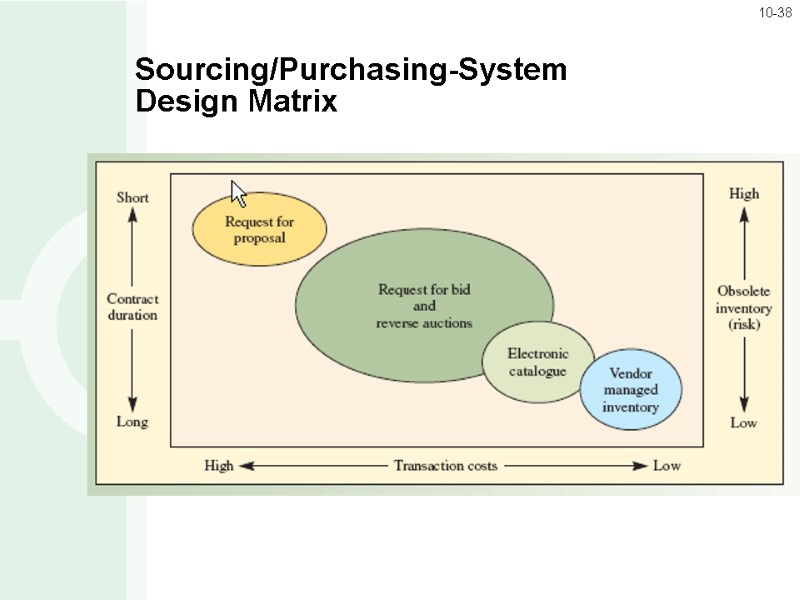

Sourcing/Purchasing-System Design Matrix 10-38

Sourcing/Purchasing-System Design Matrix 10-38

Mass Customization Mass customization is a term used to describe the ability of a company to deliver highly customized products and services to different customers The key to mass customization is effectively postponing the tasks of differentiating a product for a specific customer until the latest possible point in the supply-chain network 10-39

Mass Customization Mass customization is a term used to describe the ability of a company to deliver highly customized products and services to different customers The key to mass customization is effectively postponing the tasks of differentiating a product for a specific customer until the latest possible point in the supply-chain network 10-39

Mass Customization Mass customization is a term used to describe the ability of a company to deliver highly customized products and services to different customers The key to mass customization is effectively postponing the tasks of differentiating a product for a specific customer until the latest possible point in the supply-chain network Example: H-P customizing DeskJet printers with the power supply needed in various European countries once printers arrive at its distribution center in Germany

Mass Customization Mass customization is a term used to describe the ability of a company to deliver highly customized products and services to different customers The key to mass customization is effectively postponing the tasks of differentiating a product for a specific customer until the latest possible point in the supply-chain network Example: H-P customizing DeskJet printers with the power supply needed in various European countries once printers arrive at its distribution center in Germany

Question Bowl A typical supply chain would include which of the following? Suppliers Manufacturers Distribution All of the above None of the above Answer: d. All of the above 10-41

Question Bowl A typical supply chain would include which of the following? Suppliers Manufacturers Distribution All of the above None of the above Answer: d. All of the above 10-41

Question Bowl The supply chain measure of “Inventory Turnover” is which of the following ratios? Avg. inventory value/total costs Costs of goods sold/Avg. aggregate inventory value Total costs of goods/Avg. costs of goods Weeks worth of inventory/No. of weeks None of the above Answer: b. Costs of goods sold/Avg. aggregate inventory value 10-42

Question Bowl The supply chain measure of “Inventory Turnover” is which of the following ratios? Avg. inventory value/total costs Costs of goods sold/Avg. aggregate inventory value Total costs of goods/Avg. costs of goods Weeks worth of inventory/No. of weeks None of the above Answer: b. Costs of goods sold/Avg. aggregate inventory value 10-42

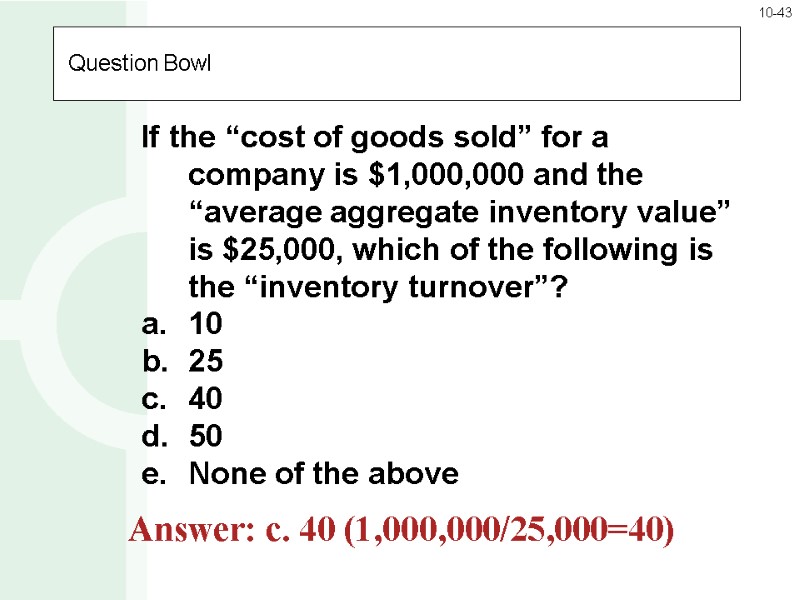

Question Bowl If the “cost of goods sold” for a company is $1,000,000 and the “average aggregate inventory value” is $25,000, which of the following is the “inventory turnover”? 10 25 40 50 None of the above Answer: c. 40 (1,000,000/25,000=40) 10-43

Question Bowl If the “cost of goods sold” for a company is $1,000,000 and the “average aggregate inventory value” is $25,000, which of the following is the “inventory turnover”? 10 25 40 50 None of the above Answer: c. 40 (1,000,000/25,000=40) 10-43

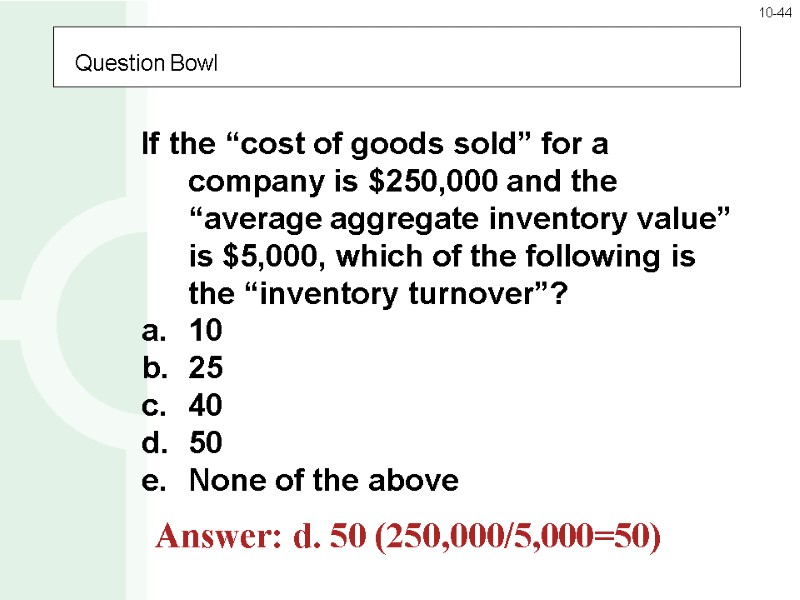

Question Bowl If the “cost of goods sold” for a company is $250,000 and the “average aggregate inventory value” is $5,000, which of the following is the “inventory turnover”? 10 25 40 50 None of the above Answer: d. 50 (250,000/5,000=50) 10-44

Question Bowl If the “cost of goods sold” for a company is $250,000 and the “average aggregate inventory value” is $5,000, which of the following is the “inventory turnover”? 10 25 40 50 None of the above Answer: d. 50 (250,000/5,000=50) 10-44

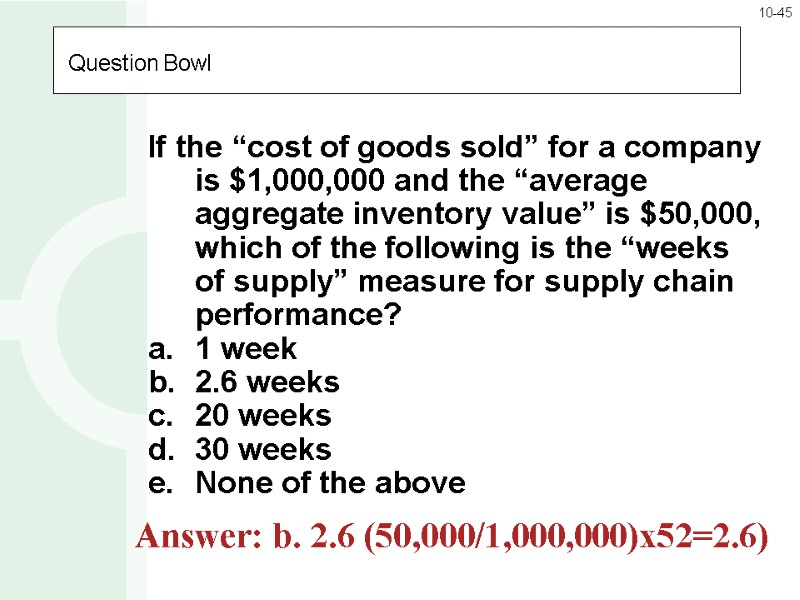

Question Bowl If the “cost of goods sold” for a company is $1,000,000 and the “average aggregate inventory value” is $50,000, which of the following is the “weeks of supply” measure for supply chain performance? 1 week 2.6 weeks 20 weeks 30 weeks None of the above Answer: b. 2.6 (50,000/1,000,000)x52=2.6) 10-45

Question Bowl If the “cost of goods sold” for a company is $1,000,000 and the “average aggregate inventory value” is $50,000, which of the following is the “weeks of supply” measure for supply chain performance? 1 week 2.6 weeks 20 weeks 30 weeks None of the above Answer: b. 2.6 (50,000/1,000,000)x52=2.6) 10-45

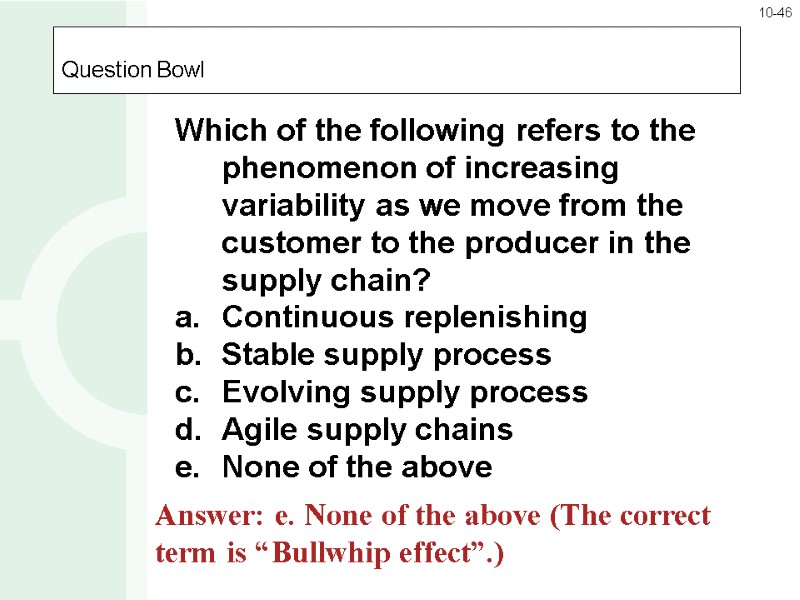

Question Bowl Which of the following refers to the phenomenon of increasing variability as we move from the customer to the producer in the supply chain? Continuous replenishing Stable supply process Evolving supply process Agile supply chains None of the above Answer: e. None of the above (The correct term is “Bullwhip effect”.) 10-46

Question Bowl Which of the following refers to the phenomenon of increasing variability as we move from the customer to the producer in the supply chain? Continuous replenishing Stable supply process Evolving supply process Agile supply chains None of the above Answer: e. None of the above (The correct term is “Bullwhip effect”.) 10-46

Question Bowl Which of the following are reasons why an organization should use “outsourcing” as a supply chain strategy? Reduces investment in assets Turns fixed costs into variable costs Gives employees a stronger career All of the above None of the above Answer: d. All of the above 10-47

Question Bowl Which of the following are reasons why an organization should use “outsourcing” as a supply chain strategy? Reduces investment in assets Turns fixed costs into variable costs Gives employees a stronger career All of the above None of the above Answer: d. All of the above 10-47

Question Bowl Which of the following “transportation modes” provides flexibility in delivery, timing and at reasonable rates for small quantities and over short distances? Rail Highway (trucking) Water Pipeline Air Answer: b. Highway (trucking) 10-48

Question Bowl Which of the following “transportation modes” provides flexibility in delivery, timing and at reasonable rates for small quantities and over short distances? Rail Highway (trucking) Water Pipeline Air Answer: b. Highway (trucking) 10-48

End of the Lecture 10-49

End of the Lecture 10-49