Lec_2_manadjmant_engl_2011.ppt

- Количество слайдов: 31

Lecture 2. Characteristic of grain mass

Lecture 2. Characteristic of grain mass

Plan of lecture 1. Characteristic of grain mass, as a object of storage. 2. Classification of grain and seed by chemical composition. 3. Physical and Physiological properties of grain mass. 4. Self-heating of grain mass.

Plan of lecture 1. Characteristic of grain mass, as a object of storage. 2. Classification of grain and seed by chemical composition. 3. Physical and Physiological properties of grain mass. 4. Self-heating of grain mass.

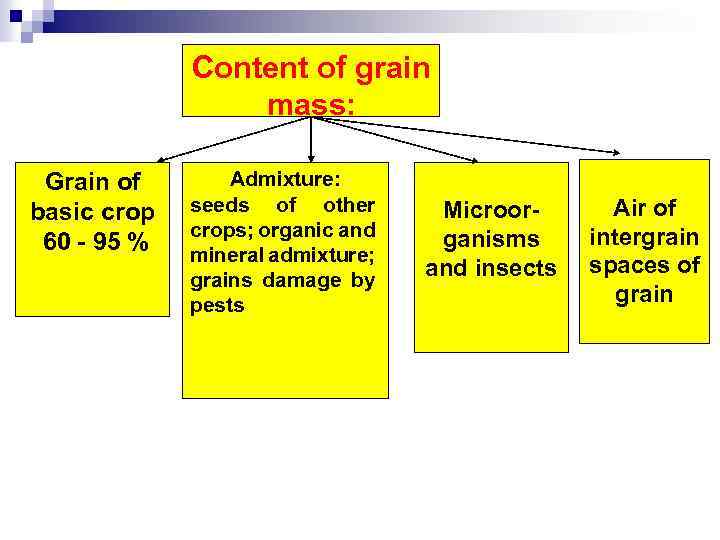

Content of grain mass: Grain of basic crop 60 - 95 % Admixture: seeds of other crops; organic and mineral admixture; grains damage by pests Microorganisms and insects Air of intergrain spaces of grain

Content of grain mass: Grain of basic crop 60 - 95 % Admixture: seeds of other crops; organic and mineral admixture; grains damage by pests Microorganisms and insects Air of intergrain spaces of grain

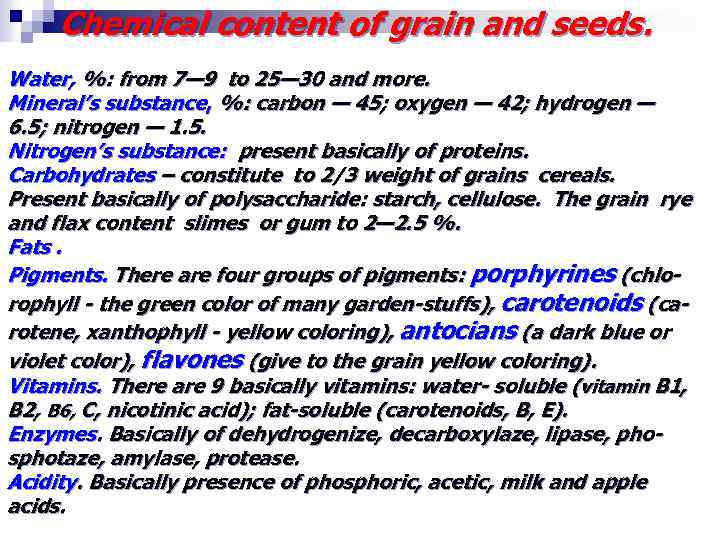

Chemical content of grain and seeds. Water, %: from 7— 9 to 25— 30 and more. Mineral’s substance, %: carbon — 45; oxygen — 42; hydrogen — 6. 5; nitrogen — 1. 5. Nitrogen’s substance: present basically of proteins. Carbohydrates – constitute to 2/3 weight of grains cereals. Present basically of polysaccharide: starch, cellulose. The grain rye and flax content slimes оr gum tо 2— 2. 5 %. Fats. Pigments. There are four groups of pigments: porphyrines (chlorophyll - the green color of many garden-stuffs), carotenoids (carotene, xanthophyll - yellow coloring), antocians (a dark blue or violet color), flavones (give to the grain yellow coloring). Vitamins. There are 9 basically vitamins: water- soluble (vitamin B 1, B 2, B 6, C, nicotinic acid); fat-soluble (carotenoids, B, Е). Enzymes. Basically of dehydrogenize, decarboxylaze, lipase, phosphotaze, amylase, protease. Acidity. Basically presence of phosphoric, acetic, milk and apple acids.

Chemical content of grain and seeds. Water, %: from 7— 9 to 25— 30 and more. Mineral’s substance, %: carbon — 45; oxygen — 42; hydrogen — 6. 5; nitrogen — 1. 5. Nitrogen’s substance: present basically of proteins. Carbohydrates – constitute to 2/3 weight of grains cereals. Present basically of polysaccharide: starch, cellulose. The grain rye and flax content slimes оr gum tо 2— 2. 5 %. Fats. Pigments. There are four groups of pigments: porphyrines (chlorophyll - the green color of many garden-stuffs), carotenoids (carotene, xanthophyll - yellow coloring), antocians (a dark blue or violet color), flavones (give to the grain yellow coloring). Vitamins. There are 9 basically vitamins: water- soluble (vitamin B 1, B 2, B 6, C, nicotinic acid); fat-soluble (carotenoids, B, Е). Enzymes. Basically of dehydrogenize, decarboxylaze, lipase, phosphotaze, amylase, protease. Acidity. Basically presence of phosphoric, acetic, milk and apple acids.

Classification grain and seeds by chemical substances: 1) rich on starch (55 - 80 %) - cereals (rye, wheat, oat, barley, rice), groats plants (buckwheat, millet); 2) rich on proteins (more than 20 %) – pulses (pea, haricot, bean, sorghum and etc. ); 3) rich on a plant oil (more than 35 %) — sunflower, flax, mustard, rape, poppy and etc. ); 4) rich at the same time on plant and essential oils (fennel, coriander, cumin and etc. ).

Classification grain and seeds by chemical substances: 1) rich on starch (55 - 80 %) - cereals (rye, wheat, oat, barley, rice), groats plants (buckwheat, millet); 2) rich on proteins (more than 20 %) – pulses (pea, haricot, bean, sorghum and etc. ); 3) rich on a plant oil (more than 35 %) — sunflower, flax, mustard, rape, poppy and etc. ); 4) rich at the same time on plant and essential oils (fennel, coriander, cumin and etc. ).

Physical properties of grain mass • Friableness; • Self sorting; • Porousness; • Sorption properties or sorption capacity - capacity for sorption and desorption of different steam and gases; • Heat conductivity; • Heat capacity; • Temperature conductivity; • Thermal-moisture conductivity.

Physical properties of grain mass • Friableness; • Self sorting; • Porousness; • Sorption properties or sorption capacity - capacity for sorption and desorption of different steam and gases; • Heat conductivity; • Heat capacity; • Temperature conductivity; • Thermal-moisture conductivity.

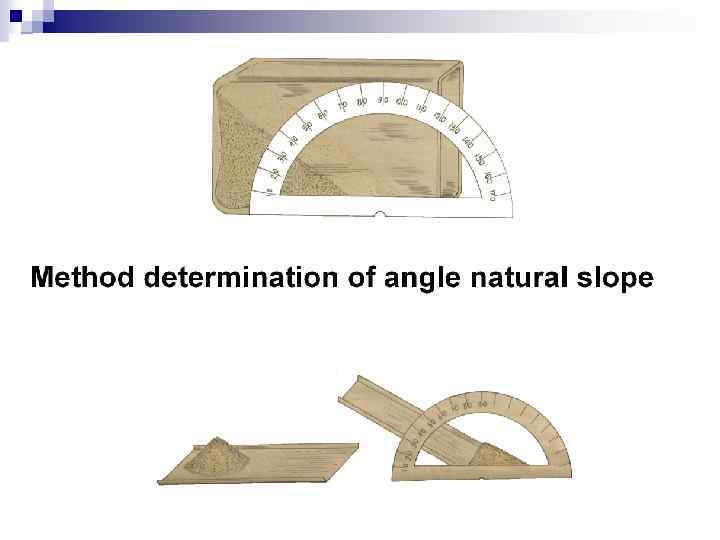

Friableness is an ability of grain and grain mass to move on the surface placed under a certain angle to horizon. Friableness of grain mass is characterized by the angle of friction or angle natural slope (the least angle between basis and slope of bulk grain for which grain mass begin to slide on a surface).

Friableness is an ability of grain and grain mass to move on the surface placed under a certain angle to horizon. Friableness of grain mass is characterized by the angle of friction or angle natural slope (the least angle between basis and slope of bulk grain for which grain mass begin to slide on a surface).

Self sorting is property of grain mass to lost the homogeneity during moving and free falling. Porousness of grain mass is presence of the intervals between its hard particles, filled by air.

Self sorting is property of grain mass to lost the homogeneity during moving and free falling. Porousness of grain mass is presence of the intervals between its hard particles, filled by air.

Sorption properties of grain mass is an ability to absorb steam from an environment, smells, different volatile matters and gases and also desorption it back. Heat conductivity of grain mass consists of its ability to carry a warmth from areas with high temperature to the areas with a lower temperature. The heat capacity of grain is characterized by the amount of warmth necessary for the increase of temperature of grain by mass 1 kg on 1 °С.

Sorption properties of grain mass is an ability to absorb steam from an environment, smells, different volatile matters and gases and also desorption it back. Heat conductivity of grain mass consists of its ability to carry a warmth from areas with high temperature to the areas with a lower temperature. The heat capacity of grain is characterized by the amount of warmth necessary for the increase of temperature of grain by mass 1 kg on 1 °С.

Temperature conductivity is speed of temperature change in a grain and its thermal inertia. Thermal-moisture conductivity is an ability of grain mass directly to transfer moisture from an area with high temperature to the areas with a lower temperature together with the stream of warmth.

Temperature conductivity is speed of temperature change in a grain and its thermal inertia. Thermal-moisture conductivity is an ability of grain mass directly to transfer moisture from an area with high temperature to the areas with a lower temperature together with the stream of warmth.

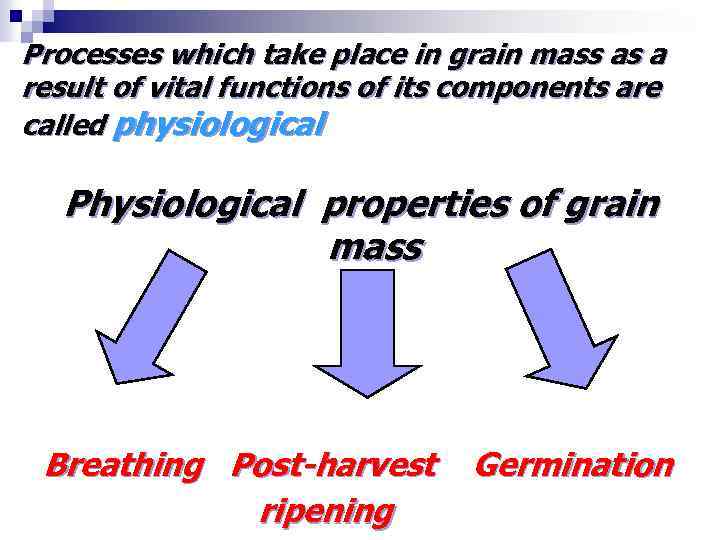

Processes which take place in grain mass as a result of vital functions of its components are called physiological Physiological properties of grain mass Breathing Post-harvest ripening Germination

Processes which take place in grain mass as a result of vital functions of its components are called physiological Physiological properties of grain mass Breathing Post-harvest ripening Germination

Breathing is an important physiology process which is the basis of exchange of matters in living organisms energy. The process of breathing of grain can be estimated by a respiratory coefficient K (correlation of volume of carbon dioxide, that was removed to the amount of the oxygen spent in the process of breathing directly) and breathing intensity. К=1 – aerobic breathing К<1 – anaerobic breathing К>1 – anaerobic breathing

Breathing is an important physiology process which is the basis of exchange of matters in living organisms energy. The process of breathing of grain can be estimated by a respiratory coefficient K (correlation of volume of carbon dioxide, that was removed to the amount of the oxygen spent in the process of breathing directly) and breathing intensity. К=1 – aerobic breathing К<1 – anaerobic breathing К>1 – anaerobic breathing

Breathing intensity is determined by the quantitative losses of mass of dry matter of grain, given off warmth, used oxygen and given off carbon dioxide by grain mass at the certain values of humidity, temperature and access of air. Intensity of breathing is expressed by milligrams or in the cube centimeters of carbon dioxide, that was given off a 1000 g dry matter of grain for day.

Breathing intensity is determined by the quantitative losses of mass of dry matter of grain, given off warmth, used oxygen and given off carbon dioxide by grain mass at the certain values of humidity, temperature and access of air. Intensity of breathing is expressed by milligrams or in the cube centimeters of carbon dioxide, that was given off a 1000 g dry matter of grain for day.

Factors which influence on the breathing intensity of grain: Ø humidity; Ø temperature; Ø degree of aeration; Ø duration of storage; Ø quality and state of grain mass.

Factors which influence on the breathing intensity of grain: Ø humidity; Ø temperature; Ø degree of aeration; Ø duration of storage; Ø quality and state of grain mass.

Grain division at the quantity of humidity: Ødry grain; Ømiddle dryness; Ømoist; Øwet.

Grain division at the quantity of humidity: Ødry grain; Ømiddle dryness; Ømoist; Øwet.

Influence of humidity on the breathing intensity: Breathing Intensity of cereals grain with humidity up to 11 -12 % is practically equal zero. The grain of middle dryness breathes from 2 till 4 times Intensity, than dry; Moist from 4 till 8 times and Wet from 20 till 30 times, Intensity than dry.

Influence of humidity on the breathing intensity: Breathing Intensity of cereals grain with humidity up to 11 -12 % is practically equal zero. The grain of middle dryness breathes from 2 till 4 times Intensity, than dry; Moist from 4 till 8 times and Wet from 20 till 30 times, Intensity than dry.

Critical humidity of grain is value of humidity when in grain appear of free moisture. The critical humidity is a level of the humidity of grain, when free moisture appears in it, so breathing intensity increases sharply. Critical humidity is within the limits of middle dryness of grain (seed).

Critical humidity of grain is value of humidity when in grain appear of free moisture. The critical humidity is a level of the humidity of grain, when free moisture appears in it, so breathing intensity increases sharply. Critical humidity is within the limits of middle dryness of grain (seed).

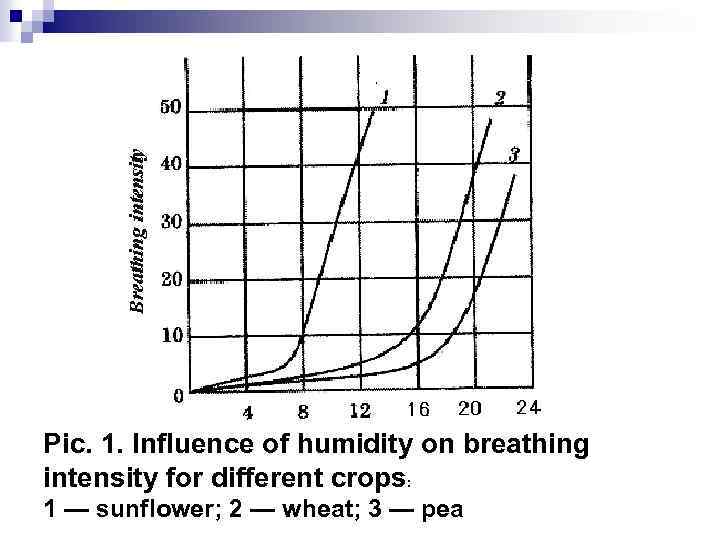

Рic. 1. Influence of humidity on breathing intensity for different crops: 1 — sunflower; 2 — wheat; 3 — pea

Рic. 1. Influence of humidity on breathing intensity for different crops: 1 — sunflower; 2 — wheat; 3 — pea

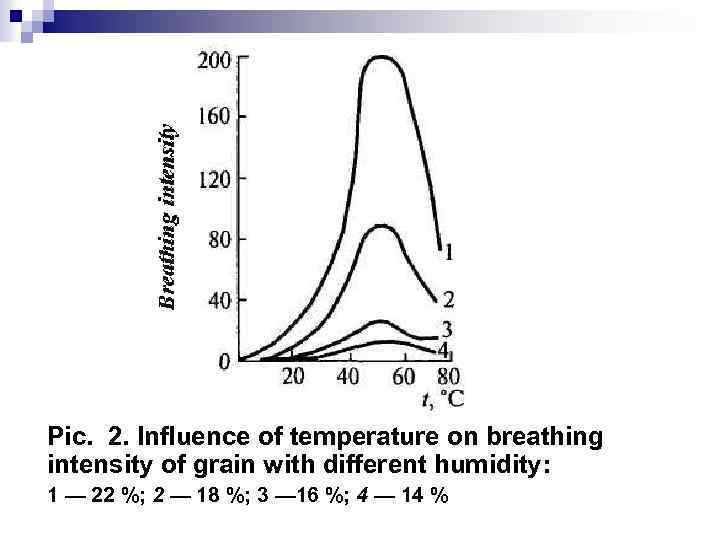

Influence of temperature on intensity of breathing The decrease of temperature considerably reduces the intensity of breathing of all living components of grain mass and increases terms of its storage (рiс. 2).

Influence of temperature on intensity of breathing The decrease of temperature considerably reduces the intensity of breathing of all living components of grain mass and increases terms of its storage (рiс. 2).

Рiс. 2. Influence of temperature on breathing intensity of grain with different humidity: 1 — 22 %; 2 — 18 %; 3 — 16 %; 4 — 14 %

Рiс. 2. Influence of temperature on breathing intensity of grain with different humidity: 1 — 22 %; 2 — 18 %; 3 — 16 %; 4 — 14 %

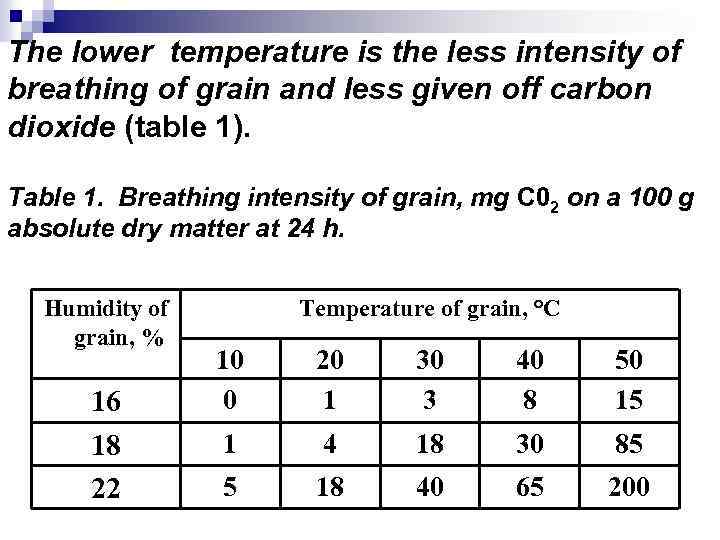

The lower temperature is the less intensity of breathing of grain and less given off carbon dioxide (table 1). Table 1. Breathing intensity of grain, mg С 02 on a 100 g absolute dry matter at 24 h. Humidity of grain, % 16 18 22 Temperature of grain, °С 10 0 20 1 30 3 40 8 50 15 1 4 18 30 85 5 18 40 65 200

The lower temperature is the less intensity of breathing of grain and less given off carbon dioxide (table 1). Table 1. Breathing intensity of grain, mg С 02 on a 100 g absolute dry matter at 24 h. Humidity of grain, % 16 18 22 Temperature of grain, °С 10 0 20 1 30 3 40 8 50 15 1 4 18 30 85 5 18 40 65 200

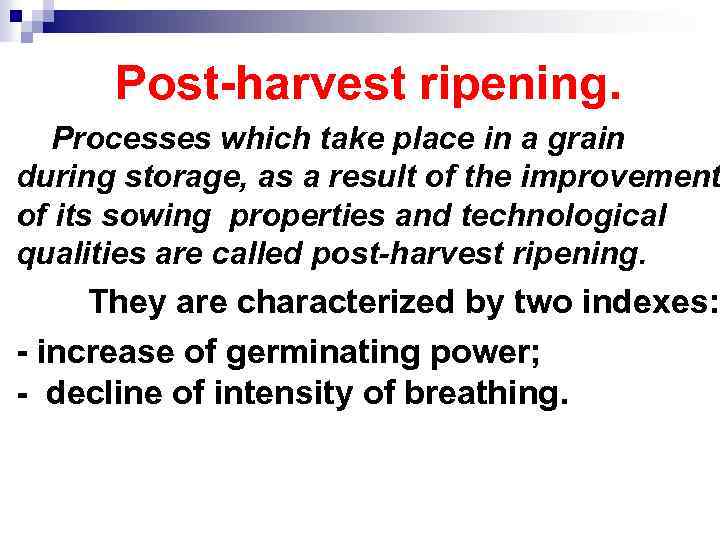

Post-harvest ripening. Processes which take place in a grain during storage, as a result of the improvement of its sowing properties and technological qualities are called post-harvest ripening. They are characterized by two indexes: - increase of germinating power; - decline of intensity of breathing.

Post-harvest ripening. Processes which take place in a grain during storage, as a result of the improvement of its sowing properties and technological qualities are called post-harvest ripening. They are characterized by two indexes: - increase of germinating power; - decline of intensity of breathing.

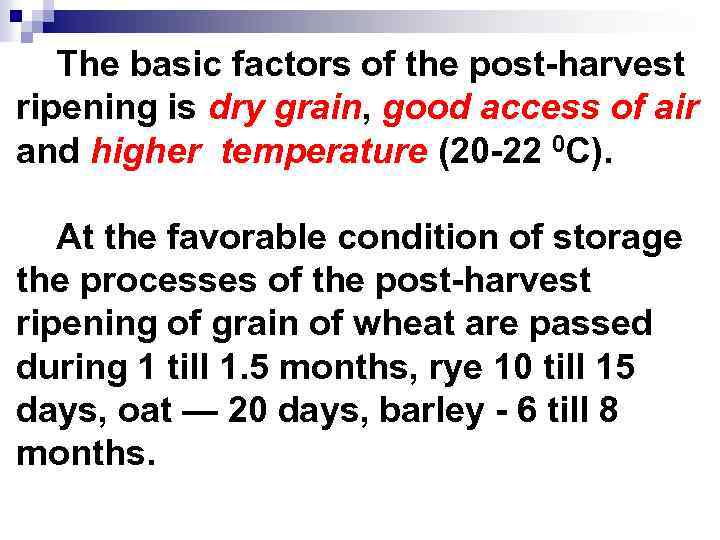

The basic factors of the post-harvest ripening is dry grain, good access of air and higher temperature (20 -22 0 С). At the favorable condition of storage the processes of the post-harvest ripening of grain of wheat are passed during 1 till 1. 5 months, rye 10 till 15 days, oat — 20 days, barley - 6 till 8 months.

The basic factors of the post-harvest ripening is dry grain, good access of air and higher temperature (20 -22 0 С). At the favorable condition of storage the processes of the post-harvest ripening of grain of wheat are passed during 1 till 1. 5 months, rye 10 till 15 days, oat — 20 days, barley - 6 till 8 months.

Germination of grain. For the germination of grain certain condition are necessary - sufficient humidity, heat and access of air. Grain begins to germinate only at absorption of drop-liquid moisture and moistening to 40 % and higher. Careful control at the humidity of grain in different layers and areas of bulk, prevention of formation of drop-liquid moisture in grain mass is the basic method prevention of grain germination at during its storage.

Germination of grain. For the germination of grain certain condition are necessary - sufficient humidity, heat and access of air. Grain begins to germinate only at absorption of drop-liquid moisture and moistening to 40 % and higher. Careful control at the humidity of grain in different layers and areas of bulk, prevention of formation of drop-liquid moisture in grain mass is the basic method prevention of grain germination at during its storage.

Self-heating of grain mass is the increase of its temperature as a result of physiology processes, which take place in it, and low heat conductivity. The physiology basis of self-heating is breathing of all living components of grain mass, which excrete of heat. The physical basis of self-heating is bad heat conductivity of grain. Formation of heat in one or another area of grain bulk exceeds the emission it in the environment. It is causes the self-heating.

Self-heating of grain mass is the increase of its temperature as a result of physiology processes, which take place in it, and low heat conductivity. The physiology basis of self-heating is breathing of all living components of grain mass, which excrete of heat. The physical basis of self-heating is bad heat conductivity of grain. Formation of heat in one or another area of grain bulk exceeds the emission it in the environment. It is causes the self-heating.

The factors, which influence on development of process self-heating: 1) Intensive breathing of grain basis crops, grain and seeds of admixtures; 2) Intensive growth of microorganisms; 3) Intensive vital activity of insects and ticks.

The factors, which influence on development of process self-heating: 1) Intensive breathing of grain basis crops, grain and seeds of admixtures; 2) Intensive growth of microorganisms; 3) Intensive vital activity of insects and ticks.

The types of self heating: Ønesting; Ølayering; Øwholing.

The types of self heating: Ønesting; Ølayering; Øwholing.

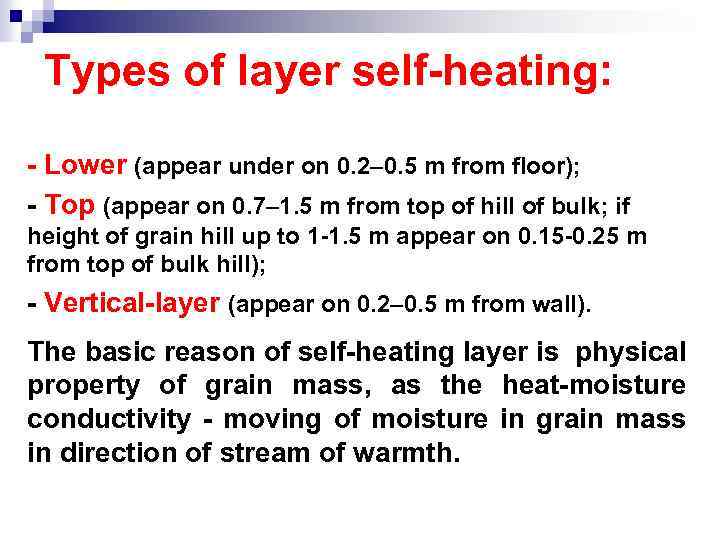

Types of layer self-heating: - Lower (appear under on 0. 2– 0. 5 m from floor); - Top (appear on 0. 7– 1. 5 m from top of hill of bulk; if height of grain hill up to 1 -1. 5 m appear on 0. 15 -0. 25 m from top of bulk hill); - Vertical-layer (appear on 0. 2– 0. 5 m from wall). The basic reason of self-heating layer is physical property of grain mass, as the heat-moisture conductivity - moving of moisture in grain mass in direction of stream of warmth.

Types of layer self-heating: - Lower (appear under on 0. 2– 0. 5 m from floor); - Top (appear on 0. 7– 1. 5 m from top of hill of bulk; if height of grain hill up to 1 -1. 5 m appear on 0. 15 -0. 25 m from top of bulk hill); - Vertical-layer (appear on 0. 2– 0. 5 m from wall). The basic reason of self-heating layer is physical property of grain mass, as the heat-moisture conductivity - moving of moisture in grain mass in direction of stream of warmth.

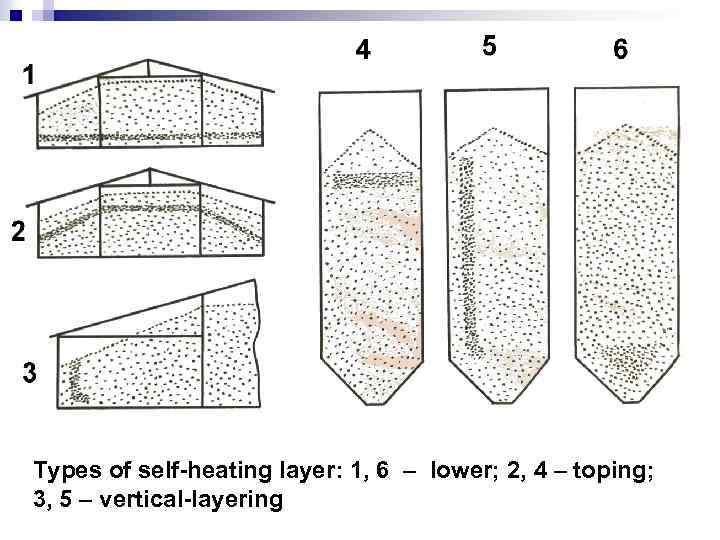

Types of self-heating layer: 1, 6 – lower; 2, 4 – toping; 3, 5 – vertical-layering

Types of self-heating layer: 1, 6 – lower; 2, 4 – toping; 3, 5 – vertical-layering

Thank you for attention.

Thank you for attention.