Lection 6 “Purchasing” • 1. The Role of Purchasing in the Supply Chain. • 2. Purchasing Activities • 3. Purchasing Research and Planning • 4. Purchasing Cost Management • 5. Managing Supplier Relationship

Lection 6 “Purchasing” • 1. The Role of Purchasing in the Supply Chain. • 2. Purchasing Activities • 3. Purchasing Research and Planning • 4. Purchasing Cost Management • 5. Managing Supplier Relationship

1. The Role of Purchasing in the Supply Chain • Purchasing refers to a business or organization attempting to acquire goods or services to accomplish the goals of the enterprise • Purchasing is responsible primarily for inbound or upstream, channel activities whereas logistics spans both inbound and outbound relationship and material flows

1. The Role of Purchasing in the Supply Chain • Purchasing refers to a business or organization attempting to acquire goods or services to accomplish the goals of the enterprise • Purchasing is responsible primarily for inbound or upstream, channel activities whereas logistics spans both inbound and outbound relationship and material flows

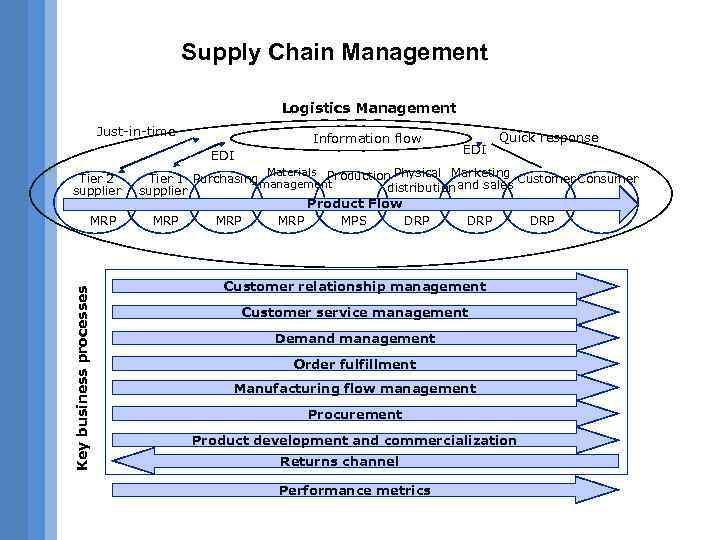

Supply Chain Management Logistics Management Just-in-time Information flow EDI Tier 2 supplier Key business processes MRP EDI Quick response Materials Production Physical Marketing Tier 1 Purchasing management Customer Consumer distribution and sales supplier Product Flow MRP MRP MPS DRP Customer relationship management Customer service management Demand management Order fulfillment Manufacturing flow management Procurement Product development and commercialization Returns channel Performance metrics DRP

Supply Chain Management Logistics Management Just-in-time Information flow EDI Tier 2 supplier Key business processes MRP EDI Quick response Materials Production Physical Marketing Tier 1 Purchasing management Customer Consumer distribution and sales supplier Product Flow MRP MRP MPS DRP Customer relationship management Customer service management Demand management Order fulfillment Manufacturing flow management Procurement Product development and commercialization Returns channel Performance metrics DRP

2. Purchasing Activities Objectives: • To meet the needs of the manufacturing function or other internal functions for which it was buying • Focused on getting the right product or service to the right place at the right time, in the right quantity, in the right condition or quality and from the right supplier at the right price • Played a role in keeping the operation running smoothly by ensuring a reliable source of supply

2. Purchasing Activities Objectives: • To meet the needs of the manufacturing function or other internal functions for which it was buying • Focused on getting the right product or service to the right place at the right time, in the right quantity, in the right condition or quality and from the right supplier at the right price • Played a role in keeping the operation running smoothly by ensuring a reliable source of supply

1. Development of the Purchasing Function – In many ways, purchasing today stand at a crossroads in its development – Activities such as purchase order placement, expediting and calling to check stock have either been eliminated or are now possible on-line with electronic data interchange (EDI)

1. Development of the Purchasing Function – In many ways, purchasing today stand at a crossroads in its development – Activities such as purchase order placement, expediting and calling to check stock have either been eliminated or are now possible on-line with electronic data interchange (EDI)

2. The Role of Purchasing in Total Customer Satisfaction – The receipt of high quality, reliable goods and services on a timely basis at a reasonable cost often directly affects customer satisfaction – An organization cannot provide its ultimate customers with better quality goods and services than it receives from its supplier. If a supplier is late with delivery or has quality problems, the quality and availability of the product or service to the customer will be affected

2. The Role of Purchasing in Total Customer Satisfaction – The receipt of high quality, reliable goods and services on a timely basis at a reasonable cost often directly affects customer satisfaction – An organization cannot provide its ultimate customers with better quality goods and services than it receives from its supplier. If a supplier is late with delivery or has quality problems, the quality and availability of the product or service to the customer will be affected

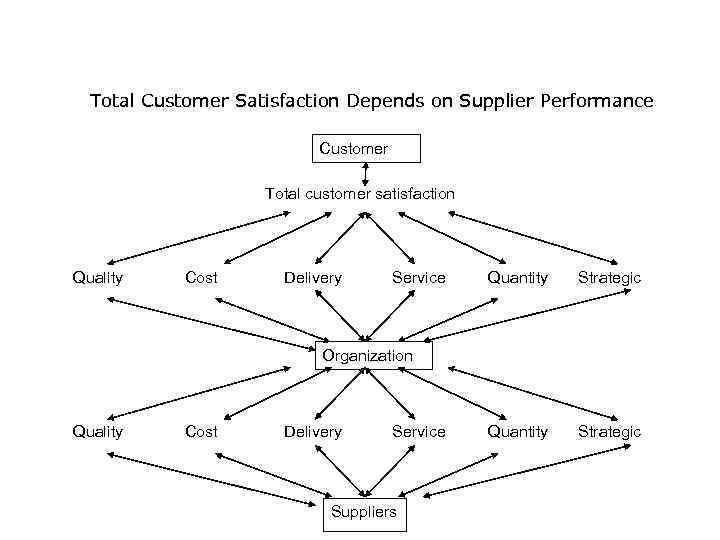

Total Customer Satisfaction Depends on Supplier Performance Customer Total customer satisfaction Quality Cost Delivery Service Quantity Strategic Organization Quality Cost Delivery Service Suppliers

Total Customer Satisfaction Depends on Supplier Performance Customer Total customer satisfaction Quality Cost Delivery Service Quantity Strategic Organization Quality Cost Delivery Service Suppliers

3. The Strategic Role of Purchasing – Is to perform sourcing related activities in a way that support the overall objectives of the organization A. Access to External Markets • Through external contacts with the supply market, purchasing can gain important about new technology, potential new materials or services, new sources of supply and changes in market conditions

3. The Strategic Role of Purchasing – Is to perform sourcing related activities in a way that support the overall objectives of the organization A. Access to External Markets • Through external contacts with the supply market, purchasing can gain important about new technology, potential new materials or services, new sources of supply and changes in market conditions

B. Supplier Development and Relationship Management • Purchasing can help support the organization’s strategic success by identifying new and existing suppliers • Getting suppliers involved early in the development of new products and services or modifications to existing offering can reduce development times • Among the primary purchasing activities are supplier selection, evaluation and ongoing management (sourcing), total quality management and purchasing planning

B. Supplier Development and Relationship Management • Purchasing can help support the organization’s strategic success by identifying new and existing suppliers • Getting suppliers involved early in the development of new products and services or modifications to existing offering can reduce development times • Among the primary purchasing activities are supplier selection, evaluation and ongoing management (sourcing), total quality management and purchasing planning

C. Relationship to Other Function • Virtually every department within an organization relies on the purchasing function for some type of information and support • Purchasing often has the same functional reporting relationship as logistics, which is helpful for coordinating materials management • Purchasing and logistics need to work closely in coordinating inbound logistics and associated material flows

C. Relationship to Other Function • Virtually every department within an organization relies on the purchasing function for some type of information and support • Purchasing often has the same functional reporting relationship as logistics, which is helpful for coordinating materials management • Purchasing and logistics need to work closely in coordinating inbound logistics and associated material flows

• 4. Supplier Selection and Evaluation – The most important activity is selecting the best supplier from among a number of supplier that can provide the needed materials – The buying process is complex because the variety of factors that must be considered when making a purchase – There are 5 steps of purchasing process for managing supplier relationship and follow up

• 4. Supplier Selection and Evaluation – The most important activity is selecting the best supplier from among a number of supplier that can provide the needed materials – The buying process is complex because the variety of factors that must be considered when making a purchase – There are 5 steps of purchasing process for managing supplier relationship and follow up

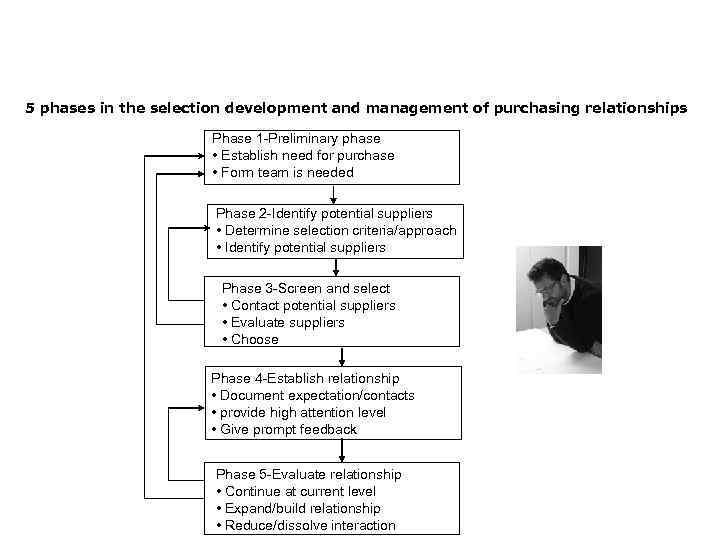

5 phases in the selection development and management of purchasing relationships Phase 1 -Preliminary phase • Establish need for purchase • Form team is needed Phase 2 -Identify potential suppliers • Determine selection criteria/approach • Identify potential suppliers Phase 3 -Screen and select • Contact potential suppliers • Evaluate suppliers • Choose Phase 4 -Establish relationship • Document expectation/contacts • provide high attention level • Give prompt feedback Phase 5 -Evaluate relationship • Continue at current level • Expand/build relationship • Reduce/dissolve interaction

5 phases in the selection development and management of purchasing relationships Phase 1 -Preliminary phase • Establish need for purchase • Form team is needed Phase 2 -Identify potential suppliers • Determine selection criteria/approach • Identify potential suppliers Phase 3 -Screen and select • Contact potential suppliers • Evaluate suppliers • Choose Phase 4 -Establish relationship • Document expectation/contacts • provide high attention level • Give prompt feedback Phase 5 -Evaluate relationship • Continue at current level • Expand/build relationship • Reduce/dissolve interaction

– Purchase Categories • There are 6 major purchase categories in most companies: – – – Component parts Raw materials Operating supplies Support equipment Process equipment Services

– Purchase Categories • There are 6 major purchase categories in most companies: – – – Component parts Raw materials Operating supplies Support equipment Process equipment Services

• Evaluating Suppliers • To determine the impact of supplier performance on productivity, performance must be measured and evaluated • A variety of evaluation procedures are possible • Most important always use consistent procedures to increase the objective of the process • The manager must identify all potential for the items being purchased • The next step is to develop a list of factors to evaluate each supplier

• Evaluating Suppliers • To determine the impact of supplier performance on productivity, performance must be measured and evaluated • A variety of evaluation procedures are possible • Most important always use consistent procedures to increase the objective of the process • The manager must identify all potential for the items being purchased • The next step is to develop a list of factors to evaluate each supplier

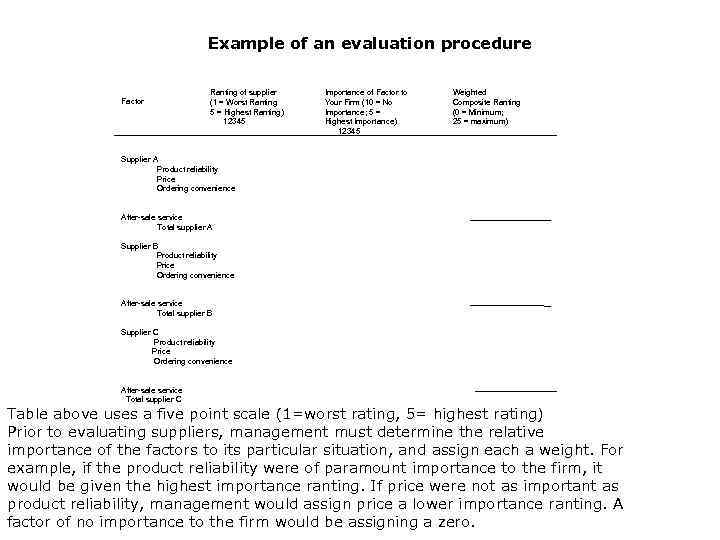

Example of an evaluation procedure Factor Ranting of supplier (1 = Worst Ranting 5 = Highest Ranting) 12345 Importance of Factor to Your Firm (10 = No Importance; 5 = Highest Importance) 12345 Weighted Composite Ranting (0 = Minimum; 25 = maximum) Supplier A Product reliability Price Ordering convenience After-sale service Total supplier A Supplier B Product reliability Price Ordering convenience After-sale service Total supplier B Supplier C Product reliability Price Ordering convenience After-sale service Total supplier C Table above uses a five point scale (1=worst rating, 5= highest rating) Prior to evaluating suppliers, management must determine the relative importance of the factors to its particular situation, and assign each a weight. For example, if the product reliability were of paramount importance to the firm, it would be given the highest importance ranting. If price were not as important as product reliability, management would assign price a lower importance ranting. A factor of no importance to the firm would be assigning a zero.

Example of an evaluation procedure Factor Ranting of supplier (1 = Worst Ranting 5 = Highest Ranting) 12345 Importance of Factor to Your Firm (10 = No Importance; 5 = Highest Importance) 12345 Weighted Composite Ranting (0 = Minimum; 25 = maximum) Supplier A Product reliability Price Ordering convenience After-sale service Total supplier A Supplier B Product reliability Price Ordering convenience After-sale service Total supplier B Supplier C Product reliability Price Ordering convenience After-sale service Total supplier C Table above uses a five point scale (1=worst rating, 5= highest rating) Prior to evaluating suppliers, management must determine the relative importance of the factors to its particular situation, and assign each a weight. For example, if the product reliability were of paramount importance to the firm, it would be given the highest importance ranting. If price were not as important as product reliability, management would assign price a lower importance ranting. A factor of no importance to the firm would be assigning a zero.

Selecting Suppliers – Selecting the right suppliers has an immediate and long term impact on the firm’s ability to serve its customer – The supplier selection process is more difficult when materials are being purchased in international markets or for international operations – Reward associated with proper supplier selection and evaluation; • Reduction in the cost of materials increase the profit margin on every unit manufactured and sold • Customer service improvement are possible because the manufacturing process can operate smoothly with no slowdowns or shutdowns

Selecting Suppliers – Selecting the right suppliers has an immediate and long term impact on the firm’s ability to serve its customer – The supplier selection process is more difficult when materials are being purchased in international markets or for international operations – Reward associated with proper supplier selection and evaluation; • Reduction in the cost of materials increase the profit margin on every unit manufactured and sold • Customer service improvement are possible because the manufacturing process can operate smoothly with no slowdowns or shutdowns

• 5. Total Quality Management – Quality management is one of the important consideration in materials acquisition – Materials of higher quality may require fewer fabrication processes or have a longer life span, resulting in lower overall product costs or higher prices for finished product – After the required quality level has being determined and specifications developed, usually by manufacturing, it becomes purchasing responsibility to secure the proper materials – The correct quality specification must be given to suppliers. The supplier that offers the best cost-quality combination that meets the specifications should be selected

• 5. Total Quality Management – Quality management is one of the important consideration in materials acquisition – Materials of higher quality may require fewer fabrication processes or have a longer life span, resulting in lower overall product costs or higher prices for finished product – After the required quality level has being determined and specifications developed, usually by manufacturing, it becomes purchasing responsibility to secure the proper materials – The correct quality specification must be given to suppliers. The supplier that offers the best cost-quality combination that meets the specifications should be selected

– One way that firms might ensure quality is through inspection of incoming materials parts. But, this is costly and time consuming – Inspection requires human resources, space, and perhaps tests equipment. In addition, incoming inventory is tied up or delayed awaiting inspection – For this reason, purchasing managers have turned to supplier certification – In the certification process, the supplier’s quality levels and processes are closely evaluated by members of the buying firm. If they “pass, ” the buying organization no longer inspects that supplier’s incoming materials.

– One way that firms might ensure quality is through inspection of incoming materials parts. But, this is costly and time consuming – Inspection requires human resources, space, and perhaps tests equipment. In addition, incoming inventory is tied up or delayed awaiting inspection – For this reason, purchasing managers have turned to supplier certification – In the certification process, the supplier’s quality levels and processes are closely evaluated by members of the buying firm. If they “pass, ” the buying organization no longer inspects that supplier’s incoming materials.

• 6. Just-in-Time (JIT) – JIT focuses on the identification and elimination of waste wherever it is found in the manufacturing system – Elimination of waste aim of reducing waste and cost throughout the entire supply chain – JIT implementation involves the initiation of a “pull” system of manufacturing (matching production to known demand) – the benefits include; significant reductions of raw material, work-in-process, and finished good inventories and large decreases in the amount of space required for the manufacturing process

• 6. Just-in-Time (JIT) – JIT focuses on the identification and elimination of waste wherever it is found in the manufacturing system – Elimination of waste aim of reducing waste and cost throughout the entire supply chain – JIT implementation involves the initiation of a “pull” system of manufacturing (matching production to known demand) – the benefits include; significant reductions of raw material, work-in-process, and finished good inventories and large decreases in the amount of space required for the manufacturing process

– A) Difficulties in Implementing JIT • One of the most frequently reasons is a lack of cooperation from supplier due to changes in the supplier’s system • the supplier is asked to manufacture in quantities that may differ from the usual lot sizes and to make frequent deliveries of small lot with precise timing • • The supplier and buyer are normally required to provide each other with access to their master production planning system, shop floor schedule, and material requirements planning system.

– A) Difficulties in Implementing JIT • One of the most frequently reasons is a lack of cooperation from supplier due to changes in the supplier’s system • the supplier is asked to manufacture in quantities that may differ from the usual lot sizes and to make frequent deliveries of small lot with precise timing • • The supplier and buyer are normally required to provide each other with access to their master production planning system, shop floor schedule, and material requirements planning system.

– B) Importance of Buyer-Supplier Communication • Suppliers are given long–range insight into the buyer’s production schedule • The schedule for the nearest several weeks is frozen allows the supplier to acquire raw materials in a stockless production mode and to supply the buyer without inventory buildups • Purchases and suppliers must cooperate and have a trusting relationship in order to convert supply chains to JIT operations • Supplier selection, single sourcing, supply management and supplier communication become critical issues for purchasing and materials managers in implementing JIT

– B) Importance of Buyer-Supplier Communication • Suppliers are given long–range insight into the buyer’s production schedule • The schedule for the nearest several weeks is frozen allows the supplier to acquire raw materials in a stockless production mode and to supply the buyer without inventory buildups • Purchases and suppliers must cooperate and have a trusting relationship in order to convert supply chains to JIT operations • Supplier selection, single sourcing, supply management and supplier communication become critical issues for purchasing and materials managers in implementing JIT

• 7. Purchase Agreement – The purchase order may specify price and overall quantity, but the supplier will deliver in accordance with a schedule or with daily production needs – The buyer expects and receives the exact quantity – Saves much time in negotiating and pricing the order

• 7. Purchase Agreement – The purchase order may specify price and overall quantity, but the supplier will deliver in accordance with a schedule or with daily production needs – The buyer expects and receives the exact quantity – Saves much time in negotiating and pricing the order

• 8. Value Analysis – When negotiating a purchase agreement, the supplier receives the buyer’s specifications and provides a bid price. – If the price is too high, the buyer may visit the supplier’s plant to review its processes – The objective is to identify areas where the supplier’s costs exceed the value added and, if possible, to modify the minimal specifications in order to reduce the supplier’s cost and the bid price.

• 8. Value Analysis – When negotiating a purchase agreement, the supplier receives the buyer’s specifications and provides a bid price. – If the price is too high, the buyer may visit the supplier’s plant to review its processes – The objective is to identify areas where the supplier’s costs exceed the value added and, if possible, to modify the minimal specifications in order to reduce the supplier’s cost and the bid price.

• 9. “Loose” Engineering Specifications/ Early Supplier Involvement – The concept of getting the supplier involved in the design process is often called early supplier involvement (ESI) – Concurrent engineering is a type of early supplier involvement where the engineers in the buying and selling firms work together on product development or product improvement. – Engineers and quality control people may pay frequent visit to a supplier’s plant to answer engineering questions and identify potential quality problem before they surface.

• 9. “Loose” Engineering Specifications/ Early Supplier Involvement – The concept of getting the supplier involved in the design process is often called early supplier involvement (ESI) – Concurrent engineering is a type of early supplier involvement where the engineers in the buying and selling firms work together on product development or product improvement. – Engineers and quality control people may pay frequent visit to a supplier’s plant to answer engineering questions and identify potential quality problem before they surface.

• 10. Control of Inbound Transportation – JIT purchasing requires steady, reliable incoming deliveries. – The objective is to avoid excessive inventory carrying costs for materials that arrive early and avoid disruptions in manufacturing operations when goods arrive late. – Therefore, the buying firms must become involved in selecting both the transportation mode and the specific carrier – For example, CTI and Ryder integrated Logistics review manufacturers production schedule pickup of the materials, pickup and time-sequence the materials, and deliver them directly to the JIT production line. .

• 10. Control of Inbound Transportation – JIT purchasing requires steady, reliable incoming deliveries. – The objective is to avoid excessive inventory carrying costs for materials that arrive early and avoid disruptions in manufacturing operations when goods arrive late. – Therefore, the buying firms must become involved in selecting both the transportation mode and the specific carrier – For example, CTI and Ryder integrated Logistics review manufacturers production schedule pickup of the materials, pickup and time-sequence the materials, and deliver them directly to the JIT production line. .

• 11. Supplier Development – A systematic organizational effort to create and maintain a network of competent suppliers and to improve various supplier capabilities that are necessary for the buying organization to meet its increasing competitive challenges – Sometimes organizations find that their current suppliers are unable to support stringent JIT quality and delivery requirements – Such organizations may search for other suppliers or work with suppliers to develop the skills needed to support JIT. Supplier development efforts are increasing as organizations form longer-team relationships with suppliers.

• 11. Supplier Development – A systematic organizational effort to create and maintain a network of competent suppliers and to improve various supplier capabilities that are necessary for the buying organization to meet its increasing competitive challenges – Sometimes organizations find that their current suppliers are unable to support stringent JIT quality and delivery requirements – Such organizations may search for other suppliers or work with suppliers to develop the skills needed to support JIT. Supplier development efforts are increasing as organizations form longer-team relationships with suppliers.

• 12. JIT II – JIT II is an innovative type of purchasing relationship which aims JIT principles at the purchasing function – In JIT II, the supplier places one of its employees, called an “in-plant, ” in the buying company’s office, replacing a purchaser, planner, and sales person. – The in-plant representative places order, practices concurrent engineering, and has full access to all of buyer’s facilities, information, and employees. – The supplier benefits include greater integration with the customer, improved communications, more efficient administrative process, and savings on “sales effort. ”

• 12. JIT II – JIT II is an innovative type of purchasing relationship which aims JIT principles at the purchasing function – In JIT II, the supplier places one of its employees, called an “in-plant, ” in the buying company’s office, replacing a purchaser, planner, and sales person. – The in-plant representative places order, practices concurrent engineering, and has full access to all of buyer’s facilities, information, and employees. – The supplier benefits include greater integration with the customer, improved communications, more efficient administrative process, and savings on “sales effort. ”

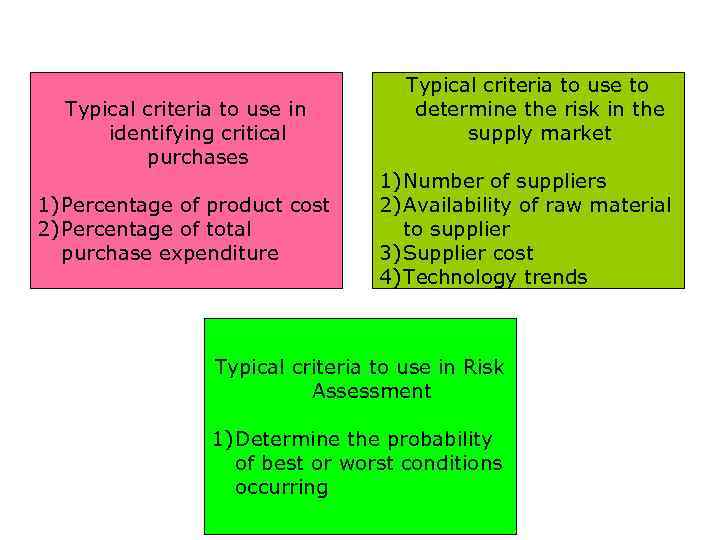

3. Purchasing Research and Planning – Strategic Planning for Purchasing • Strategic planning for purchasing involves the identification of critical purchase, supply market analysis, risk assessment, and strategy development and implementation • It is important to determine whether materials problems or shortages might jeopardize current or future production of new or existing products, whether materials quality can be expected to change, whether price are likely to increase or decrease, • and the appropriateness of forward • buying.

3. Purchasing Research and Planning – Strategic Planning for Purchasing • Strategic planning for purchasing involves the identification of critical purchase, supply market analysis, risk assessment, and strategy development and implementation • It is important to determine whether materials problems or shortages might jeopardize current or future production of new or existing products, whether materials quality can be expected to change, whether price are likely to increase or decrease, • and the appropriateness of forward • buying.

Strategic Planning for Purchasing Risk Assessment Supply Market Analysis Identification of critical purchase Strategy Development and implementation

Strategic Planning for Purchasing Risk Assessment Supply Market Analysis Identification of critical purchase Strategy Development and implementation

Typical criteria to use in identifying critical purchases 1) Percentage of product cost 2) Percentage of total purchase expenditure Typical criteria to use to determine the risk in the supply market 1) Number of suppliers 2) Availability of raw material to supplier 3) Supplier cost 4) Technology trends Typical criteria to use in Risk Assessment 1) Determine the probability of best or worst conditions occurring

Typical criteria to use in identifying critical purchases 1) Percentage of product cost 2) Percentage of total purchase expenditure Typical criteria to use to determine the risk in the supply market 1) Number of suppliers 2) Availability of raw material to supplier 3) Supplier cost 4) Technology trends Typical criteria to use in Risk Assessment 1) Determine the probability of best or worst conditions occurring

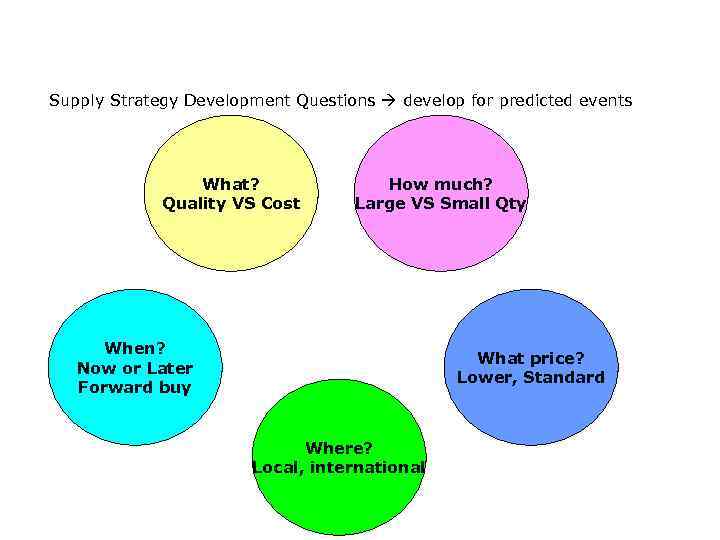

Supply Strategy Development Questions develop for predicted events What? Quality VS Cost How much? Large VS Small Qty When? Now or Later Forward buy What price? Lower, Standard Where? Local, international

Supply Strategy Development Questions develop for predicted events What? Quality VS Cost How much? Large VS Small Qty When? Now or Later Forward buy What price? Lower, Standard Where? Local, international

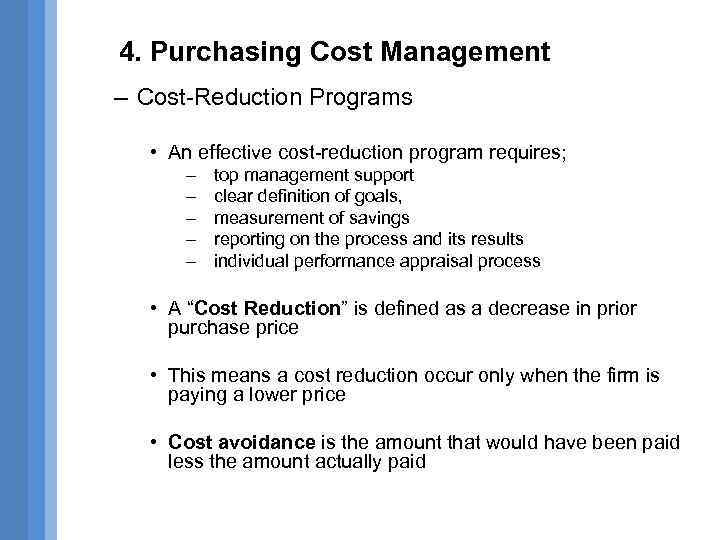

4. Purchasing Cost Management – Cost-Reduction Programs • An effective cost-reduction program requires; – – – top management support clear definition of goals, measurement of savings reporting on the process and its results individual performance appraisal process • A “Cost Reduction” is defined as a decrease in prior purchase price • This means a cost reduction occur only when the firm is paying a lower price • Cost avoidance is the amount that would have been paid less the amount actually paid

4. Purchasing Cost Management – Cost-Reduction Programs • An effective cost-reduction program requires; – – – top management support clear definition of goals, measurement of savings reporting on the process and its results individual performance appraisal process • A “Cost Reduction” is defined as a decrease in prior purchase price • This means a cost reduction occur only when the firm is paying a lower price • Cost avoidance is the amount that would have been paid less the amount actually paid

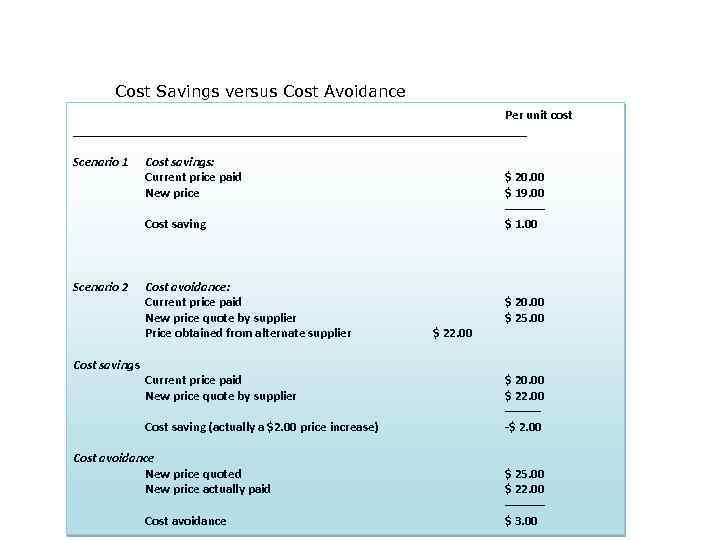

Cost Savings versus Cost Avoidance Per unit cost ___________________________________ Scenario 1 Cost savings: Current price paid New price $ 20. 00 $ 19. 00 -----$ 1. 00 Cost saving Scenario 2 Cost savings Cost avoidance: Current price paid New price quote by supplier Price obtained from alternate supplier Current price paid New price quote by supplier Cost saving (actually a $2. 00 price increase) Cost avoidance New price quoted New price actually paid Cost avoidance $ 22. 00 $ 20. 00 $ 25. 00 $ 20. 00 $ 22. 00 -----$ 2. 00 $ 25. 00 $ 22. 00 -----$ 3. 00

Cost Savings versus Cost Avoidance Per unit cost ___________________________________ Scenario 1 Cost savings: Current price paid New price $ 20. 00 $ 19. 00 -----$ 1. 00 Cost saving Scenario 2 Cost savings Cost avoidance: Current price paid New price quote by supplier Price obtained from alternate supplier Current price paid New price quote by supplier Cost saving (actually a $2. 00 price increase) Cost avoidance New price quoted New price actually paid Cost avoidance $ 22. 00 $ 20. 00 $ 25. 00 $ 20. 00 $ 22. 00 -----$ 2. 00 $ 25. 00 $ 22. 00 -----$ 3. 00

– Price Change Management • It is important to work with suppliers to restrict price increase to a reasonable and equitable level • Purchasing should work with the supplier to offset price increase through other improvements, such as reduced delivery lead times, better service, or other opportunities • To restrict price increases, management should require price protection clauses and advance notification of 30, 60, 90 days for price increases • Purchasing should determine the impact of engineering changes on product cost before it recommends making these changes

– Price Change Management • It is important to work with suppliers to restrict price increase to a reasonable and equitable level • Purchasing should work with the supplier to offset price increase through other improvements, such as reduced delivery lead times, better service, or other opportunities • To restrict price increases, management should require price protection clauses and advance notification of 30, 60, 90 days for price increases • Purchasing should determine the impact of engineering changes on product cost before it recommends making these changes

Handling Price Increase Requests From Suppliers Determine the reason for the price change request Justification of the price change by suppliers Review the price change by management Strategies to deal with price increases Alternatives for reducing other price elements to offset the price increase

Handling Price Increase Requests From Suppliers Determine the reason for the price change request Justification of the price change by suppliers Review the price change by management Strategies to deal with price increases Alternatives for reducing other price elements to offset the price increase

– Forward Buying versus Speculative Buying • Forward buying buy more of a product than is required for current consumption to protect the organization from anticipated shortages or to delay the impact of rising prices • When using this strategy, the purchasing manager must evaluate the trade-off between inventory carrying cost increases and the risk of supply constriction or increased prices • Purchasing should determine the impact of engineering changes on product cost before it recommends making these changes

– Forward Buying versus Speculative Buying • Forward buying buy more of a product than is required for current consumption to protect the organization from anticipated shortages or to delay the impact of rising prices • When using this strategy, the purchasing manager must evaluate the trade-off between inventory carrying cost increases and the risk of supply constriction or increased prices • Purchasing should determine the impact of engineering changes on product cost before it recommends making these changes

– Forward Buying versus Speculative Buying • Speculative buying purchases made not for internal consumption, but to resell at a later date for profit • Speculative goods may be the same as goods purchased for consumption, but the quantities purchased will be in excess of current or future needs • An example occurs in diverting of retail goods

– Forward Buying versus Speculative Buying • Speculative buying purchases made not for internal consumption, but to resell at a later date for profit • Speculative goods may be the same as goods purchased for consumption, but the quantities purchased will be in excess of current or future needs • An example occurs in diverting of retail goods

– Volume Contract • Way to leverage purchase requirements over time, between various business units/ locations in the company • As a result of combining purchases can reduce purchase prices and administration costs • An increase in the purchase quantity can enable suppliers to reduce their costs and prices as a result of production/ purchasing economies • Cumulative volume discount allows a buyer to combine purchase volume and getting lower prices • Non-cumulative discount the price based on the amount of each order

– Volume Contract • Way to leverage purchase requirements over time, between various business units/ locations in the company • As a result of combining purchases can reduce purchase prices and administration costs • An increase in the purchase quantity can enable suppliers to reduce their costs and prices as a result of production/ purchasing economies • Cumulative volume discount allows a buyer to combine purchase volume and getting lower prices • Non-cumulative discount the price based on the amount of each order

– Price Change Management • It is important to work with suppliers to restrict price increase to a reasonable and equitable level • Purchasing should work with the supplier to offset price increase through other improvements, such as reduced delivery lead times, better service, or other opportunities • To restrict price increases, management should require price protection clauses and advance notification of 30, 60, 90 days for price increases

– Price Change Management • It is important to work with suppliers to restrict price increase to a reasonable and equitable level • Purchasing should work with the supplier to offset price increase through other improvements, such as reduced delivery lead times, better service, or other opportunities • To restrict price increases, management should require price protection clauses and advance notification of 30, 60, 90 days for price increases

– Stockless Purchasing • Arrangement in which a supplier holds the items ordered by the customer in its own warehouse, and releases them as and when required by the customer • Is a means of reducing material-related costs such as unit purchase price, transportation, inventory and administration • The objectives of stockless purchasing are to; – – Lower inventory levels Reduce the supplier base Reduce administrative cost and paperwork Provide for timely delivery of material directly to the user • Purchasing should determine the impact of engineering changes on product cost before it recommends making these changes

– Stockless Purchasing • Arrangement in which a supplier holds the items ordered by the customer in its own warehouse, and releases them as and when required by the customer • Is a means of reducing material-related costs such as unit purchase price, transportation, inventory and administration • The objectives of stockless purchasing are to; – – Lower inventory levels Reduce the supplier base Reduce administrative cost and paperwork Provide for timely delivery of material directly to the user • Purchasing should determine the impact of engineering changes on product cost before it recommends making these changes

5. Managing Supplier Relationship – Partnership Defined • A partnership is a tailored business relationship based on mutual trust, openness, shared risk and shared rewards that yields a competitive advantage, resulting in business performance greater than would be achieved by the firms individually

5. Managing Supplier Relationship – Partnership Defined • A partnership is a tailored business relationship based on mutual trust, openness, shared risk and shared rewards that yields a competitive advantage, resulting in business performance greater than would be achieved by the firms individually

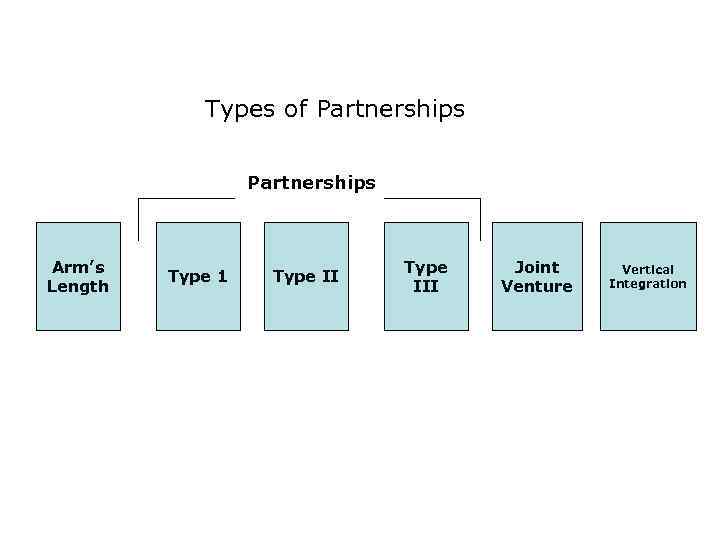

Types of Partnerships Arm’s Length Type 1 Type III Joint Venture Vertical Integration

Types of Partnerships Arm’s Length Type 1 Type III Joint Venture Vertical Integration

– Arm’s Length – a seller typically offers standard product/ services to a wide range of customer who receive standard terms and conditions – When the exchanges end, the relationship ends – Type I – The organization involved recognize each other as partners and on a limited basis coordinate activities and planning. – The partnership usually has a short term focus and involves only one division or functional area within each organization

– Arm’s Length – a seller typically offers standard product/ services to a wide range of customer who receive standard terms and conditions – When the exchanges end, the relationship ends – Type I – The organization involved recognize each other as partners and on a limited basis coordinate activities and planning. – The partnership usually has a short term focus and involves only one division or functional area within each organization

– Type II – The organizations involved progress beyond coordination of activities to integration of activities – Although not expected to last “forever”, the partnerships has a long term horizon – Multiple divisions and functions within the firm are involved in the partnerships – Type III – The organizations share a significant level of integration – Each party views the other as an extension of their own firm – Typically no “end date” for the partnerships exists

– Type II – The organizations involved progress beyond coordination of activities to integration of activities – Although not expected to last “forever”, the partnerships has a long term horizon – Multiple divisions and functions within the firm are involved in the partnerships – Type III – The organizations share a significant level of integration – Each party views the other as an extension of their own firm – Typically no “end date” for the partnerships exists

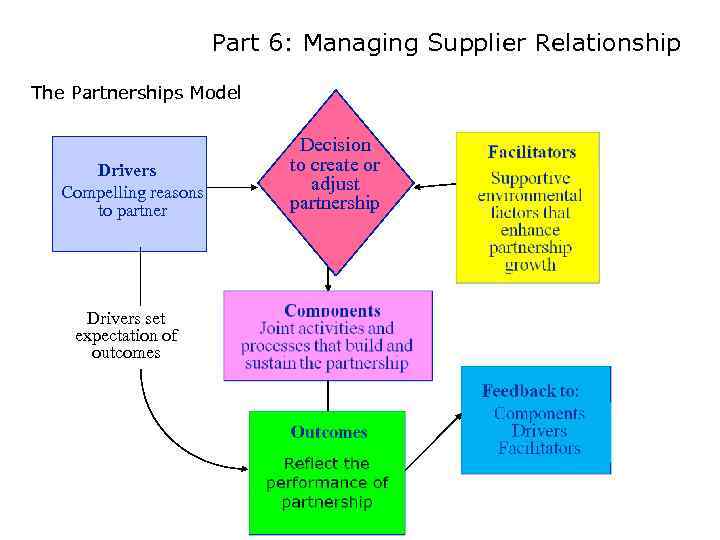

Part 6: Managing Supplier Relationship The Partnerships Model Drivers Compelling reasons to partner Drivers set expectation of outcomes Decision to create or adjust partnership

Part 6: Managing Supplier Relationship The Partnerships Model Drivers Compelling reasons to partner Drivers set expectation of outcomes Decision to create or adjust partnership

– Drivers – Both parties must believe that they will receive benefits in one or more areas – The primary potential benefits that drive the desire to partner include: • • Asset/cost efficiencies Customer service improvement Marketing advantage Profit stability – Facilitators – Are elements of a corporate environment that allow a partnerships to grow and strengthen – Facilitator include: • • Corporate compatibility Similar managerial philosophy and techniques Mutuality Symmetry

– Drivers – Both parties must believe that they will receive benefits in one or more areas – The primary potential benefits that drive the desire to partner include: • • Asset/cost efficiencies Customer service improvement Marketing advantage Profit stability – Facilitators – Are elements of a corporate environment that allow a partnerships to grow and strengthen – Facilitator include: • • Corporate compatibility Similar managerial philosophy and techniques Mutuality Symmetry

– Components – Are the activities and processes that management establishes and control throughout the life of partnerships – Components include; planning, joint operating controls, communications, trust and commitment; and financial management – Outcomes And Feedback – To evaluate the effectiveness of the relationship

– Components – Are the activities and processes that management establishes and control throughout the life of partnerships – Components include; planning, joint operating controls, communications, trust and commitment; and financial management – Outcomes And Feedback – To evaluate the effectiveness of the relationship