9.0930Fr-SE-Kemper-Extraction-Fundamentals.pptx

- Количество слайдов: 38

Extraction Fundamentals: Impact on Extractor Design & Operation CRUSHING SHORTCOURSE Kiev, Ukraine 5 April 2013 Tim Kemper Global Technical Director, Solvent Extraction

Extraction Fundamentals: Impact on Extractor Design & Operation CRUSHING SHORTCOURSE Kiev, Ukraine 5 April 2013 Tim Kemper Global Technical Director, Solvent Extraction

Oilseed microstructure

Oilseed microstructure

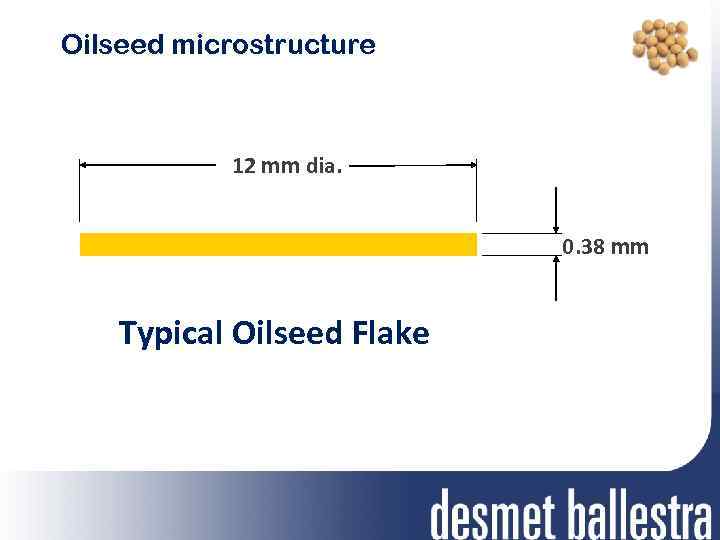

Oilseed microstructure 12 mm dia. 0. 38 mm Typical Oilseed Flake

Oilseed microstructure 12 mm dia. 0. 38 mm Typical Oilseed Flake

Oilseed microstructure Lets zoom in for a closer look Typical Oilseed Flake

Oilseed microstructure Lets zoom in for a closer look Typical Oilseed Flake

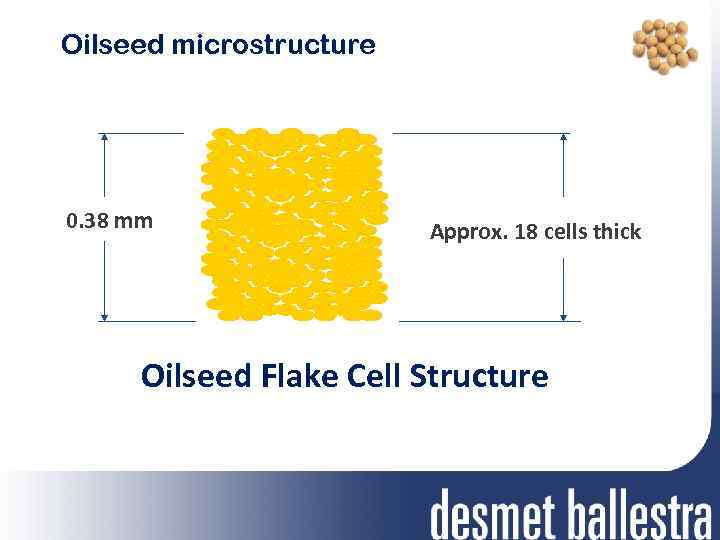

Oilseed microstructure 0. 38 mm Approx. 18 cells thick Oilseed Flake Cell Structure

Oilseed microstructure 0. 38 mm Approx. 18 cells thick Oilseed Flake Cell Structure

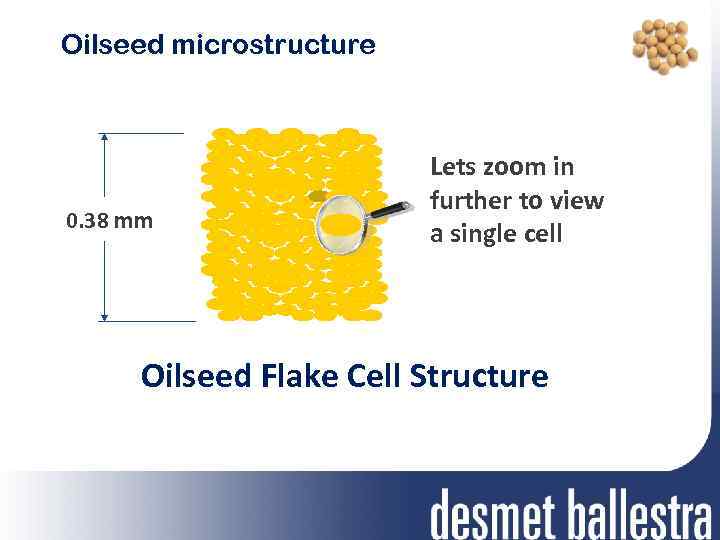

Oilseed microstructure 0. 38 mm Lets zoom in further to view a single cell Oilseed Flake Cell Structure

Oilseed microstructure 0. 38 mm Lets zoom in further to view a single cell Oilseed Flake Cell Structure

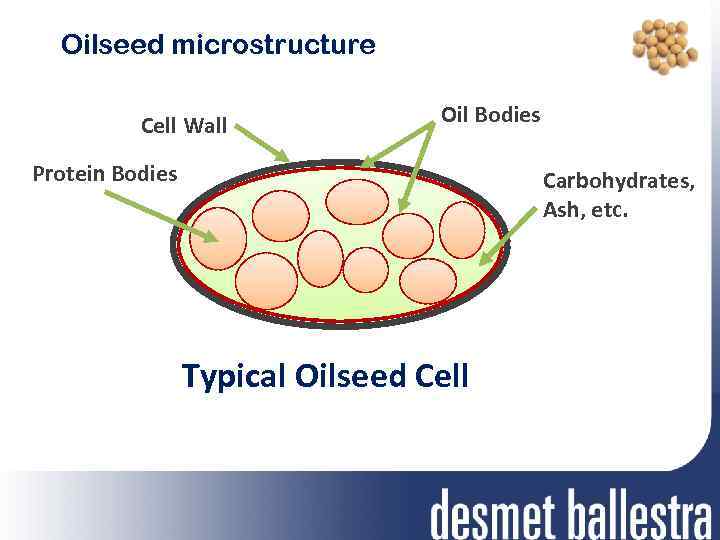

Oilseed microstructure Cell Wall Oil Bodies Protein Bodies Carbohydrates, Ash, etc. Typical Oilseed Cell

Oilseed microstructure Cell Wall Oil Bodies Protein Bodies Carbohydrates, Ash, etc. Typical Oilseed Cell

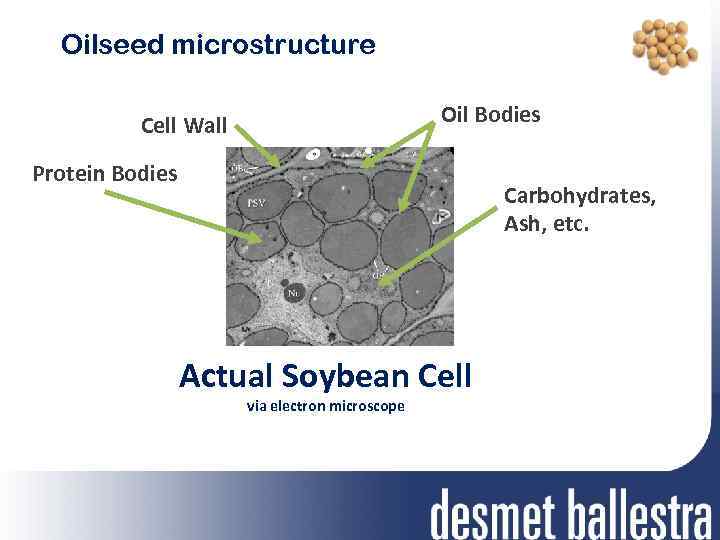

Oilseed microstructure Oil Bodies Cell Wall Protein Bodies Carbohydrates, Ash, etc. Actual Soybean Cell via electron microscope

Oilseed microstructure Oil Bodies Cell Wall Protein Bodies Carbohydrates, Ash, etc. Actual Soybean Cell via electron microscope

Solvent Extraction Process

Solvent Extraction Process

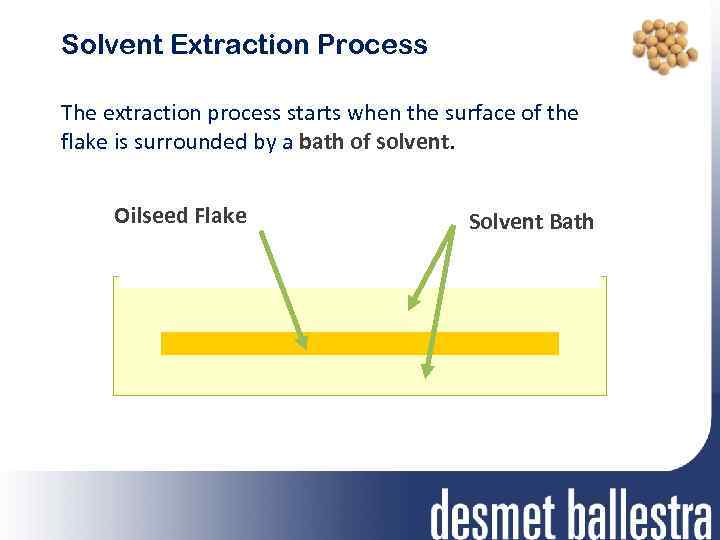

Solvent Extraction Process The extraction process starts when the surface of the flake is surrounded by a bath of solvent. Oilseed Flake Solvent Bath

Solvent Extraction Process The extraction process starts when the surface of the flake is surrounded by a bath of solvent. Oilseed Flake Solvent Bath

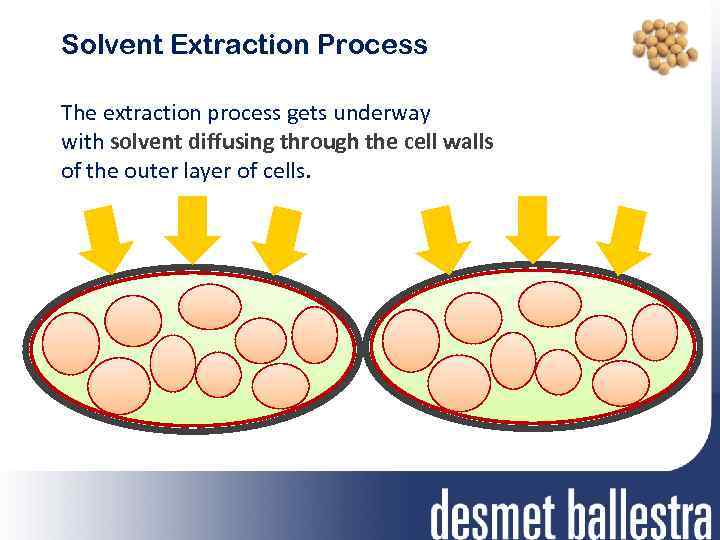

Solvent Extraction Process The extraction process gets underway with solvent diffusing through the cell walls of the outer layer of cells.

Solvent Extraction Process The extraction process gets underway with solvent diffusing through the cell walls of the outer layer of cells.

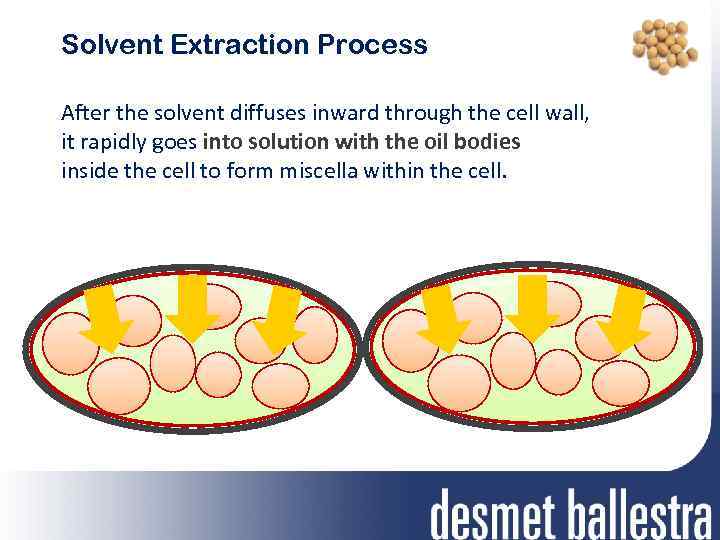

Solvent Extraction Process After the solvent diffuses inward through the cell wall, it rapidly goes into solution with the oil bodies inside the cell to form miscella within the cell.

Solvent Extraction Process After the solvent diffuses inward through the cell wall, it rapidly goes into solution with the oil bodies inside the cell to form miscella within the cell.

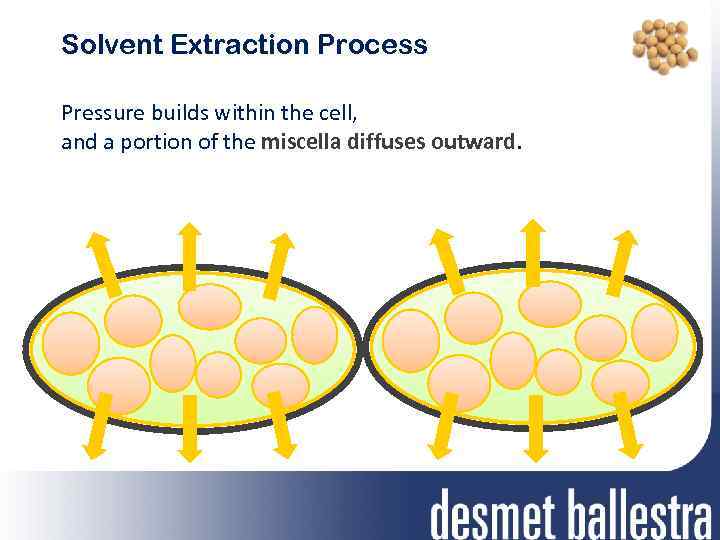

Solvent Extraction Process Pressure builds within the cell, and a portion of the miscella diffuses outward.

Solvent Extraction Process Pressure builds within the cell, and a portion of the miscella diffuses outward.

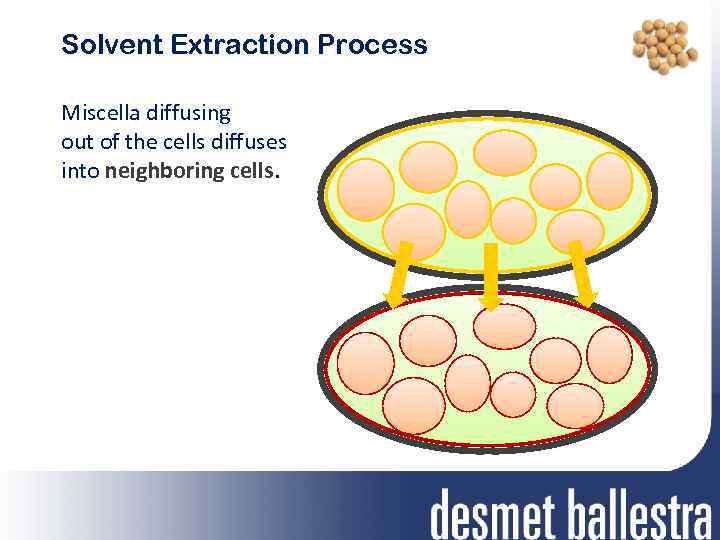

Solvent Extraction Process Miscella diffusing out of the cells diffuses into neighboring cells.

Solvent Extraction Process Miscella diffusing out of the cells diffuses into neighboring cells.

Solvent Extraction Process The process of inward diffusion, solution, pressurization & outward diffusion continues toward the center of the flake.

Solvent Extraction Process The process of inward diffusion, solution, pressurization & outward diffusion continues toward the center of the flake.

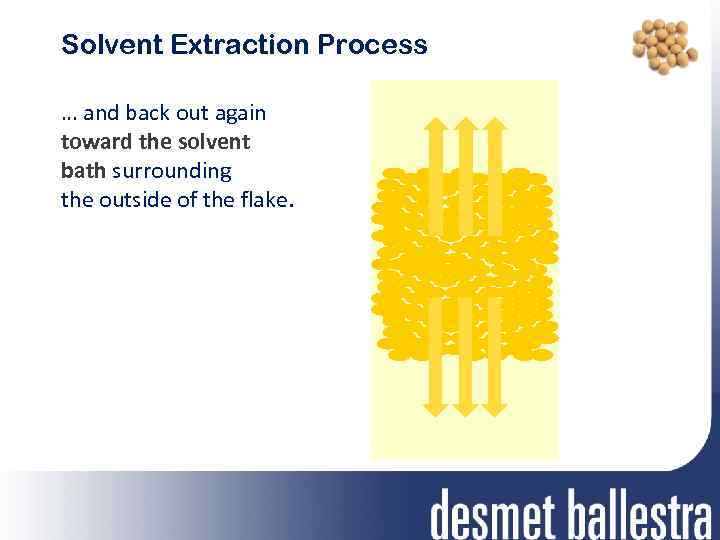

Solvent Extraction Process … and back out again toward the solvent bath surrounding the outside of the flake.

Solvent Extraction Process … and back out again toward the solvent bath surrounding the outside of the flake.

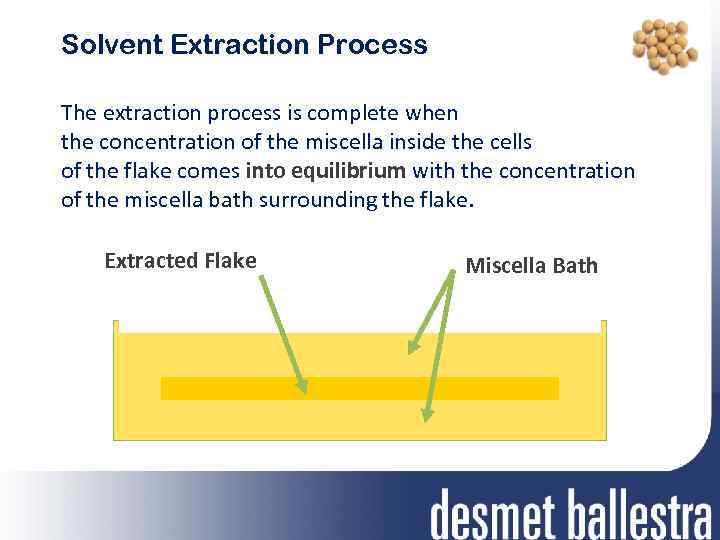

Solvent Extraction Process The extraction process is complete when the concentration of the miscella inside the cells of the flake comes into equilibrium with the concentration of the miscella bath surrounding the flake. Extracted Flake Miscella Bath

Solvent Extraction Process The extraction process is complete when the concentration of the miscella inside the cells of the flake comes into equilibrium with the concentration of the miscella bath surrounding the flake. Extracted Flake Miscella Bath

Solvent Extraction Parameters

Solvent Extraction Parameters

Solvent Extraction Parameters 1. 2. 3. 4. 5. 6. CONTACT TIME FLAKE THICKNESS TEMPERATURE MISCELLA FLUX RATE SOLVENT RETENTION NUMBER OF STAGES Six Extracti on Parame ters

Solvent Extraction Parameters 1. 2. 3. 4. 5. 6. CONTACT TIME FLAKE THICKNESS TEMPERATURE MISCELLA FLUX RATE SOLVENT RETENTION NUMBER OF STAGES Six Extracti on Parame ters

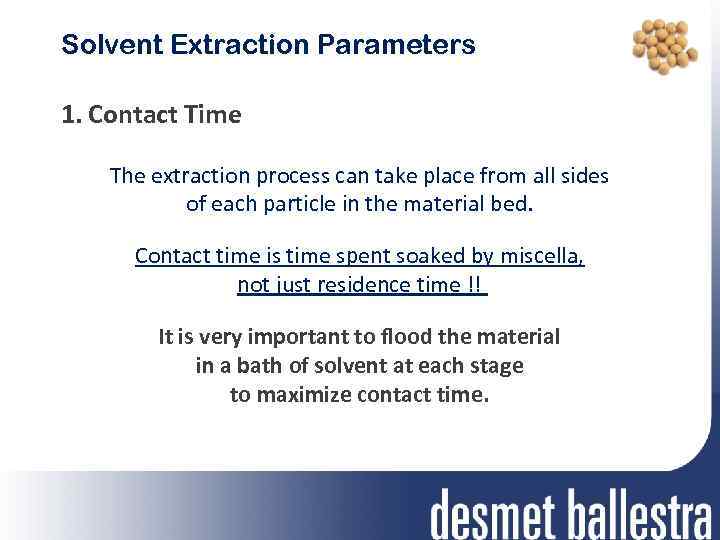

Solvent Extraction Parameters 1. Contact Time The extraction process can take place from all sides of each particle in the material bed. Contact time is time spent soaked by miscella, not just residence time !! It is very important to flood the material in a bath of solvent at each stage to maximize contact time.

Solvent Extraction Parameters 1. Contact Time The extraction process can take place from all sides of each particle in the material bed. Contact time is time spent soaked by miscella, not just residence time !! It is very important to flood the material in a bath of solvent at each stage to maximize contact time.

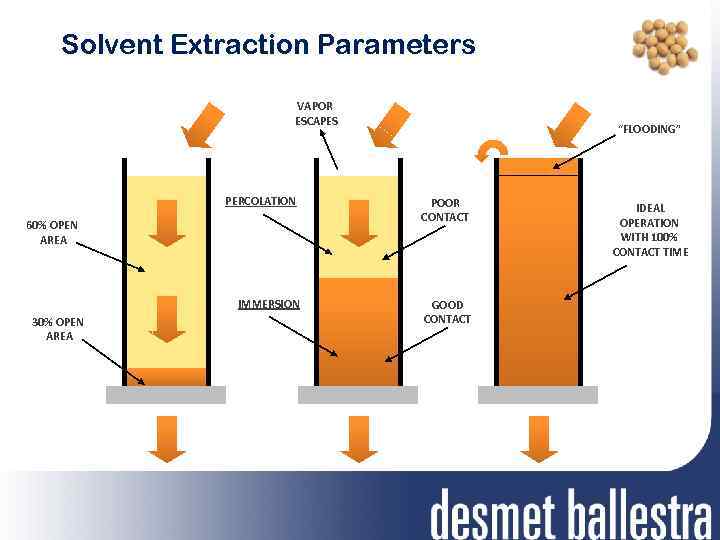

Solvent Extraction Parameters VAPOR ESCAPES “FLOODING” PERCOLATION POOR CONTACT IMMERSION GOOD CONTACT 60% OPEN AREA 30% OPEN AREA IDEAL OPERATION WITH 100% CONTACT TIME

Solvent Extraction Parameters VAPOR ESCAPES “FLOODING” PERCOLATION POOR CONTACT IMMERSION GOOD CONTACT 60% OPEN AREA 30% OPEN AREA IDEAL OPERATION WITH 100% CONTACT TIME

Solvent Extraction Parameters 1. Contact Time With 0. 38 mm thick flakes and 60°C, it takes 5 minutes of contact time in each stage to reach equilibrium. If contact time is insufficient in any given extraction stage, then that stage will not reach equilibrium. Residual oil in meal will increase !!

Solvent Extraction Parameters 1. Contact Time With 0. 38 mm thick flakes and 60°C, it takes 5 minutes of contact time in each stage to reach equilibrium. If contact time is insufficient in any given extraction stage, then that stage will not reach equilibrium. Residual oil in meal will increase !!

Solvent Extraction Parameters 2. Flake Thickness 20% thinner flakes (0. 38 mm 0. 30 mm) decrease the time required for the miscella in the cells to reach equilibrium with the surrounding miscella by over 20%, reducing contact time needed from 5 minutes to under 4 minutes per stage. 20% thinner flakes require about 1. 5 kwh per ton additional energy to create, adding significantly to operational costs.

Solvent Extraction Parameters 2. Flake Thickness 20% thinner flakes (0. 38 mm 0. 30 mm) decrease the time required for the miscella in the cells to reach equilibrium with the surrounding miscella by over 20%, reducing contact time needed from 5 minutes to under 4 minutes per stage. 20% thinner flakes require about 1. 5 kwh per ton additional energy to create, adding significantly to operational costs.

Solvent Extraction Parameters 2. Flake Thickness 20% thinner flakes (0. 38 mm 0. 30 mm) decrease the miscella flux rate (downward miscella velocity) through the flake bed by 40%, significantly moving back the location where the miscella exits the material bed through the screen floor. In summary, 0. 38 mm thick flakes reach equilibrium in 5 minutes of contact time, and minimize flaking operational costs. The extractor should be sized large enough to accommodate 0. 38 mm thick flakes.

Solvent Extraction Parameters 2. Flake Thickness 20% thinner flakes (0. 38 mm 0. 30 mm) decrease the miscella flux rate (downward miscella velocity) through the flake bed by 40%, significantly moving back the location where the miscella exits the material bed through the screen floor. In summary, 0. 38 mm thick flakes reach equilibrium in 5 minutes of contact time, and minimize flaking operational costs. The extractor should be sized large enough to accommodate 0. 38 mm thick flakes.

Solvent Extraction Parameters 3. Temperature The higher the extractor operating temperature, the faster the miscella diffuses through cell walls, and the faster the cells come into equilibrium with the surrounding miscella. At the azeotropic temperature of 61 -62°C, surface moisture and solvent evaporate off together. Surface moisture evaporating off also helps improve extraction efficiency.

Solvent Extraction Parameters 3. Temperature The higher the extractor operating temperature, the faster the miscella diffuses through cell walls, and the faster the cells come into equilibrium with the surrounding miscella. At the azeotropic temperature of 61 -62°C, surface moisture and solvent evaporate off together. Surface moisture evaporating off also helps improve extraction efficiency.

Solvent Extraction Parameters 3. Temperature Commercial hexane boiling range is 67 -69°C, and if the extractor is operated too close to the boiling range, excessive evaporation and over-pressurization will take place, losing significant solvent. When balancing extraction efficiency with safety and environmental concerns, the extractor should ideally be operated at or just under the azeotropic temperature at 60 -62°C.

Solvent Extraction Parameters 3. Temperature Commercial hexane boiling range is 67 -69°C, and if the extractor is operated too close to the boiling range, excessive evaporation and over-pressurization will take place, losing significant solvent. When balancing extraction efficiency with safety and environmental concerns, the extractor should ideally be operated at or just under the azeotropic temperature at 60 -62°C.

Solvent Extraction Parameters 4. Miscella Flux rate Miscella flux rate is the rate which miscella descends down through the material bed. How the material is prepared has a big impact on the miscella flux rate: Good quality expanded soybean pellets 49 m 3/h/m 2 or 1. 71 m/min down through expandates Good quality 0. 38 mm soybean flakes 19. 5 m 3/h/m 2 or 0. 58 m/min down through flakes Good quality 0. 30 mm soybean flakes 12 m 3/h/m 2 or 0. 34/min down through flakes

Solvent Extraction Parameters 4. Miscella Flux rate Miscella flux rate is the rate which miscella descends down through the material bed. How the material is prepared has a big impact on the miscella flux rate: Good quality expanded soybean pellets 49 m 3/h/m 2 or 1. 71 m/min down through expandates Good quality 0. 38 mm soybean flakes 19. 5 m 3/h/m 2 or 0. 58 m/min down through flakes Good quality 0. 30 mm soybean flakes 12 m 3/h/m 2 or 0. 34/min down through flakes

Solvent Extraction Parameters 4. Miscella Flux rate The orientation of miscella collection hoppers under the material bed is designed to be in the ideal location to catch the proper miscella stage. If miscella flux rate reduces significantly, the miscella will descend to a later miscella collection hopper and contaminate a weaker miscella stage, causing residual oil to increase.

Solvent Extraction Parameters 4. Miscella Flux rate The orientation of miscella collection hoppers under the material bed is designed to be in the ideal location to catch the proper miscella stage. If miscella flux rate reduces significantly, the miscella will descend to a later miscella collection hopper and contaminate a weaker miscella stage, causing residual oil to increase.

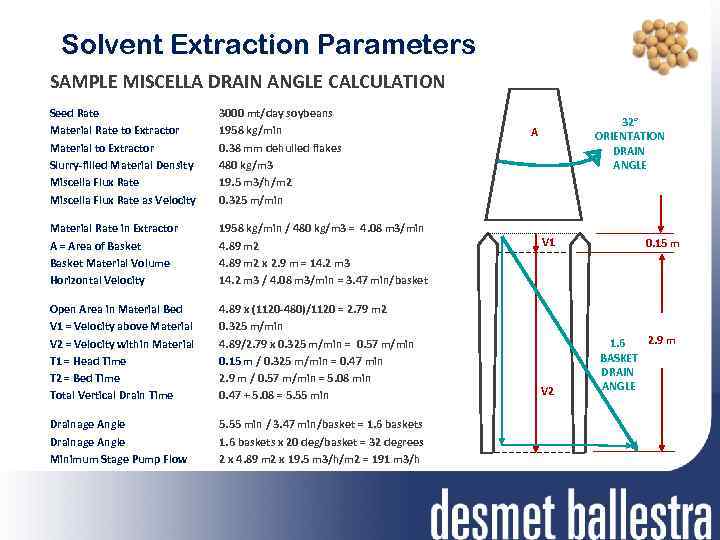

Solvent Extraction Parameters SAMPLE MISCELLA DRAIN ANGLE CALCULATION Seed Rate Material Rate to Extractor Material to Extractor Slurry-filled Material Density Miscella Flux Rate as Velocity 3000 mt/day soybeans 1958 kg/min 0. 38 mm dehulled flakes 480 kg/m 3 19. 5 m 3/h/m 2 0. 325 m/min Material Rate in Extractor A = Area of Basket Material Volume Horizontal Velocity 1958 kg/min / 480 kg/m 3 = 4. 08 m 3/min 4. 89 m 2 x 2. 9 m = 14. 2 m 3 / 4. 08 m 3/min = 3. 47 min/basket Open Area in Material Bed V 1 = Velocity above Material V 2 = Velocity within Material T 1 = Head Time T 2 = Bed Time Total Vertical Drain Time 4. 89 x (1120 -480)/1120 = 2. 79 m 2 0. 325 m/min 4. 89/2. 79 x 0. 325 m/min = 0. 57 m/min 0. 15 m / 0. 325 m/min = 0. 47 min 2. 9 m / 0. 57 m/min = 5. 08 min 0. 47 + 5. 08 = 5. 55 min Drainage Angle Minimum Stage Pump Flow 5. 55 min / 3. 47 min/basket = 1. 6 baskets x 20 deg/basket = 32 degrees 2 x 4. 89 m 2 x 19. 5 m 3/h/m 2 = 191 m 3/h 32° ORIENTATION DRAIN ANGLE A V 1 V 2 0. 15 m 2. 9 m 1. 6 BASKET DRAIN ANGLE

Solvent Extraction Parameters SAMPLE MISCELLA DRAIN ANGLE CALCULATION Seed Rate Material Rate to Extractor Material to Extractor Slurry-filled Material Density Miscella Flux Rate as Velocity 3000 mt/day soybeans 1958 kg/min 0. 38 mm dehulled flakes 480 kg/m 3 19. 5 m 3/h/m 2 0. 325 m/min Material Rate in Extractor A = Area of Basket Material Volume Horizontal Velocity 1958 kg/min / 480 kg/m 3 = 4. 08 m 3/min 4. 89 m 2 x 2. 9 m = 14. 2 m 3 / 4. 08 m 3/min = 3. 47 min/basket Open Area in Material Bed V 1 = Velocity above Material V 2 = Velocity within Material T 1 = Head Time T 2 = Bed Time Total Vertical Drain Time 4. 89 x (1120 -480)/1120 = 2. 79 m 2 0. 325 m/min 4. 89/2. 79 x 0. 325 m/min = 0. 57 m/min 0. 15 m / 0. 325 m/min = 0. 47 min 2. 9 m / 0. 57 m/min = 5. 08 min 0. 47 + 5. 08 = 5. 55 min Drainage Angle Minimum Stage Pump Flow 5. 55 min / 3. 47 min/basket = 1. 6 baskets x 20 deg/basket = 32 degrees 2 x 4. 89 m 2 x 19. 5 m 3/h/m 2 = 191 m 3/h 32° ORIENTATION DRAIN ANGLE A V 1 V 2 0. 15 m 2. 9 m 1. 6 BASKET DRAIN ANGLE

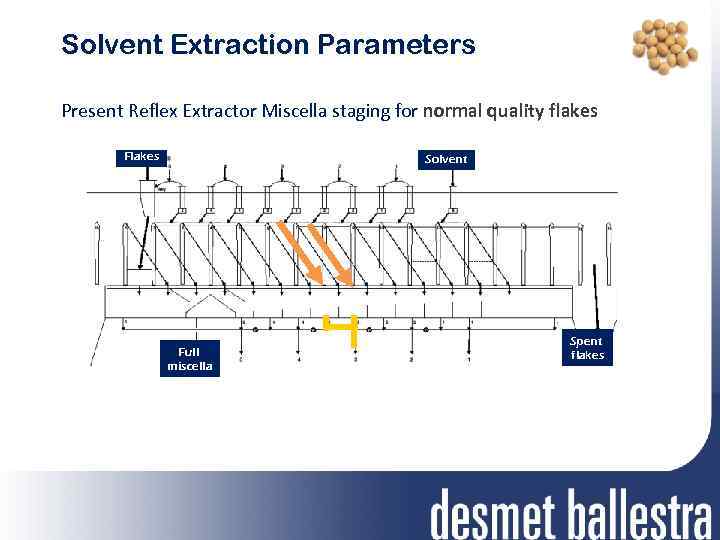

Solvent Extraction Parameters Present Reflex Extractor Miscella staging for normal quality flakes Flakes Solvent Full miscella Spent flakes

Solvent Extraction Parameters Present Reflex Extractor Miscella staging for normal quality flakes Flakes Solvent Full miscella Spent flakes

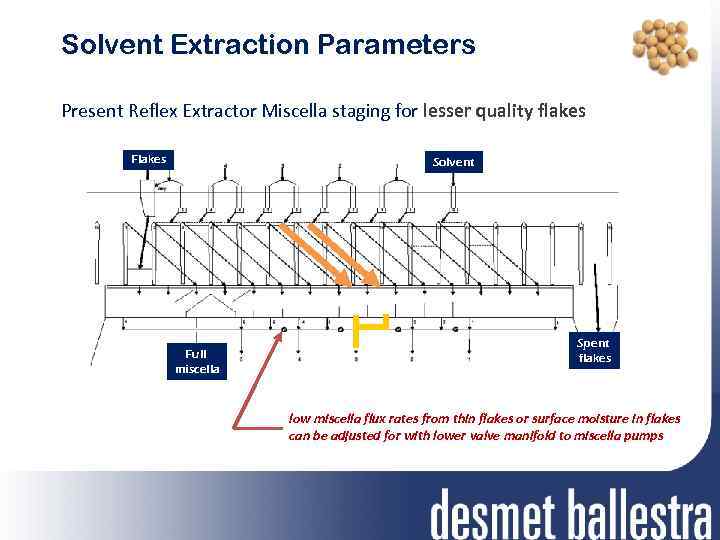

Solvent Extraction Parameters Present Reflex Extractor Miscella staging for lesser quality flakes Flakes Solvent Full miscella Spent flakes low miscella flux rates from thin flakes or surface moisture in flakes can be adjusted for with lower valve manifold to miscella pumps

Solvent Extraction Parameters Present Reflex Extractor Miscella staging for lesser quality flakes Flakes Solvent Full miscella Spent flakes low miscella flux rates from thin flakes or surface moisture in flakes can be adjusted for with lower valve manifold to miscella pumps

Solvent Extraction Parameters 4. Miscella Flux rate Minimizing surface moisture going to the extractor through good flaking mill aspiration and good expander pellet drying improves the miscella flux rate. Minimizing fines going to the extractor through more uniform grain drying, adequate tempering time, coarser cracking and proper material handling improves the miscella flux rate.

Solvent Extraction Parameters 4. Miscella Flux rate Minimizing surface moisture going to the extractor through good flaking mill aspiration and good expander pellet drying improves the miscella flux rate. Minimizing fines going to the extractor through more uniform grain drying, adequate tempering time, coarser cracking and proper material handling improves the miscella flux rate.

Solvent Extraction Parameters 5. Solvent Retention The volume of the cells that was once oil (18 -20%) will fill up with the weakest stage of miscella (0. 5% oil) and be carried to the DT. Additional miscella will also be soaked into the cell, and will also coat the surface of the flake going to the DT, increasing solvent retention to 30%. The lower the solvent retention to the DT, the less oil (0. 5% oil with solvent) will be carried along, thus reducing residual oil in the meal.

Solvent Extraction Parameters 5. Solvent Retention The volume of the cells that was once oil (18 -20%) will fill up with the weakest stage of miscella (0. 5% oil) and be carried to the DT. Additional miscella will also be soaked into the cell, and will also coat the surface of the flake going to the DT, increasing solvent retention to 30%. The lower the solvent retention to the DT, the less oil (0. 5% oil with solvent) will be carried along, thus reducing residual oil in the meal.

Solvent Extraction Parameters 5. Solvent Retention Adequate dripping time in the extractor is the most cost effective means of minimizing solvent retention. Increasing the percentage of expanded pellets increases the percentage of ruptured cell walls to further reduce solvent retention down to 26%. However, expanders also increases upstream operational costs.

Solvent Extraction Parameters 5. Solvent Retention Adequate dripping time in the extractor is the most cost effective means of minimizing solvent retention. Increasing the percentage of expanded pellets increases the percentage of ruptured cell walls to further reduce solvent retention down to 26%. However, expanders also increases upstream operational costs.

Solvent Extraction Parameters 6. Number of stages For an extractor to achieve 0. 5% oil in white flakes, with 30% solvent retention, the last, weakest miscella concentration can not exceed 0. 5% oil. If an extractor had 1 miscella stage, then full miscella would need to be 0. 5% oil to achieve 0. 5% oil in white flakes. This would require a tremendous fresh hexane flow and would be cost prohibitive in distillation energy.

Solvent Extraction Parameters 6. Number of stages For an extractor to achieve 0. 5% oil in white flakes, with 30% solvent retention, the last, weakest miscella concentration can not exceed 0. 5% oil. If an extractor had 1 miscella stage, then full miscella would need to be 0. 5% oil to achieve 0. 5% oil in white flakes. This would require a tremendous fresh hexane flow and would be cost prohibitive in distillation energy.

Solvent Extraction Parameters 6. Number of stages In theory, if a countercurrent extractor reaches complete equilibrium in 4 miscella stages, it can reach a weakest miscella concentration under 0. 5% with a full miscella concentration of 25% and achieve 0. 5% oil in white flakes. In the real world, it is difficult for every miscella stage to reach complete equilibrium, so extractors need at least 5 stages (one excess). More stages increase safety factor at the expense of higher pump energy and maintenance.

Solvent Extraction Parameters 6. Number of stages In theory, if a countercurrent extractor reaches complete equilibrium in 4 miscella stages, it can reach a weakest miscella concentration under 0. 5% with a full miscella concentration of 25% and achieve 0. 5% oil in white flakes. In the real world, it is difficult for every miscella stage to reach complete equilibrium, so extractors need at least 5 stages (one excess). More stages increase safety factor at the expense of higher pump energy and maintenance.

Solvent Extraction Parameters 1. 2. 3. 4. 5. 6. CONTACT TIME FLAKE THICKNESS TEMPERATURE MISCELLA FLUX RATE SOLVENT RETENTION NUMBER OF STAGES Six Extracti on Parame ters

Solvent Extraction Parameters 1. 2. 3. 4. 5. 6. CONTACT TIME FLAKE THICKNESS TEMPERATURE MISCELLA FLUX RATE SOLVENT RETENTION NUMBER OF STAGES Six Extracti on Parame ters

Thank you! CRUSHING SHORTCOURSE Kiev, Ukraine April 2013 Tim Kemper Global Technical Director, Solvent Extraction

Thank you! CRUSHING SHORTCOURSE Kiev, Ukraine April 2013 Tim Kemper Global Technical Director, Solvent Extraction