Coordination Polymerization Ziegler Natta Processes Stereoregular Polymerization Cationic

39680-ch5_coordinationpolymerization_daly.ppt

- Количество слайдов: 31

Coordination Polymerization Ziegler Natta Processes

Coordination Polymerization Ziegler Natta Processes

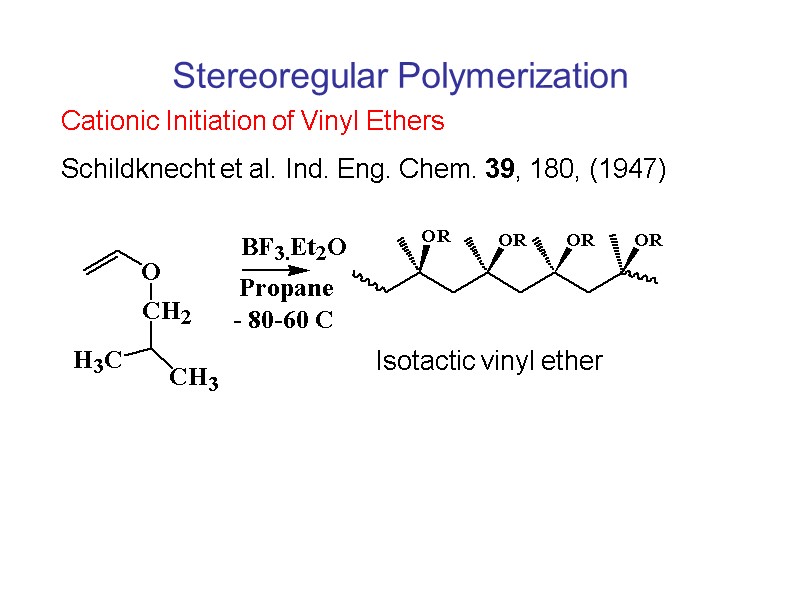

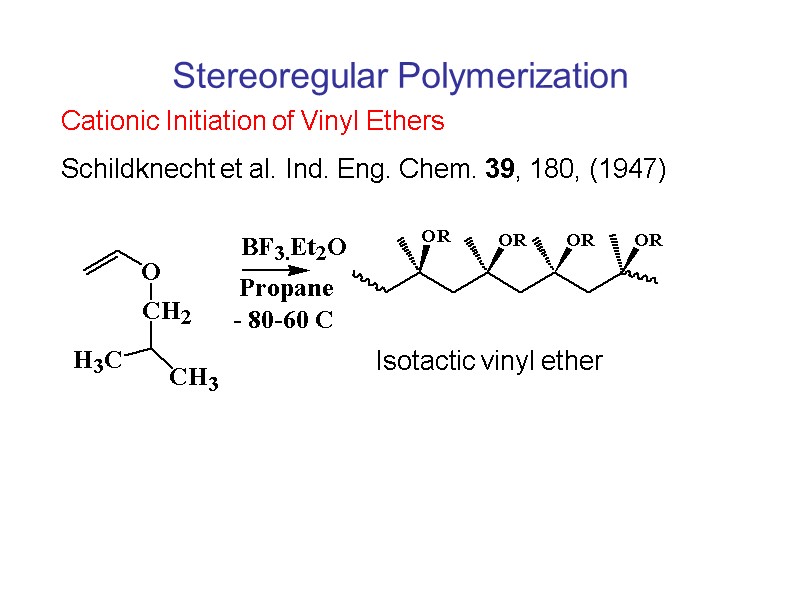

Stereoregular Polymerization Cationic Initiation of Vinyl Ethers Schildknecht et al. Ind. Eng. Chem. 39, 180, (1947) Isotactic vinyl ether

Stereoregular Polymerization Cationic Initiation of Vinyl Ethers Schildknecht et al. Ind. Eng. Chem. 39, 180, (1947) Isotactic vinyl ether

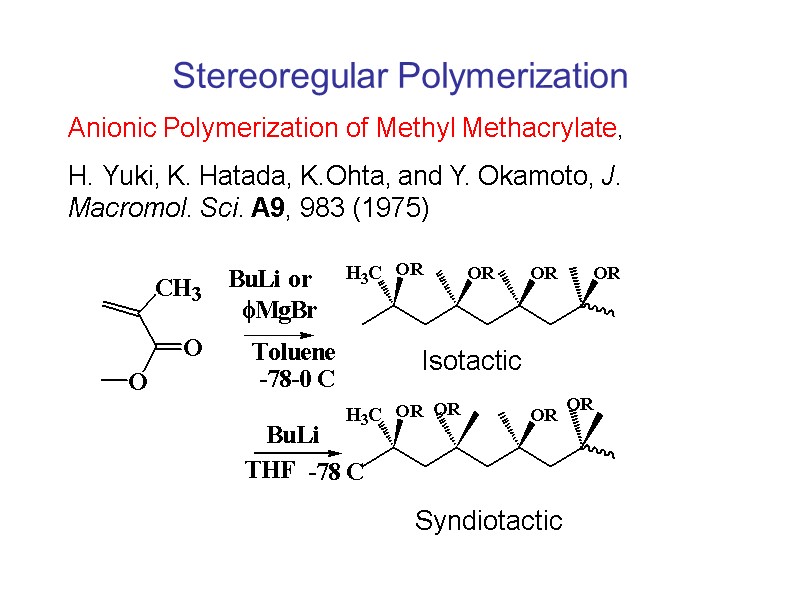

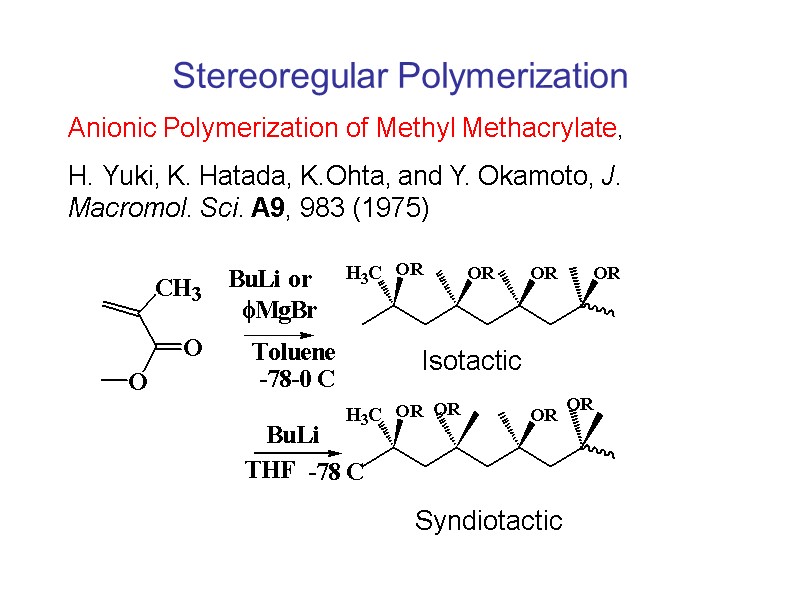

Stereoregular Polymerization Anionic Polymerization of Methyl Methacrylate, H. Yuki, K. Hatada, K.Ohta, and Y. Okamoto, J. Macromol. Sci. A9, 983 (1975) Isotactic Syndiotactic

Stereoregular Polymerization Anionic Polymerization of Methyl Methacrylate, H. Yuki, K. Hatada, K.Ohta, and Y. Okamoto, J. Macromol. Sci. A9, 983 (1975) Isotactic Syndiotactic

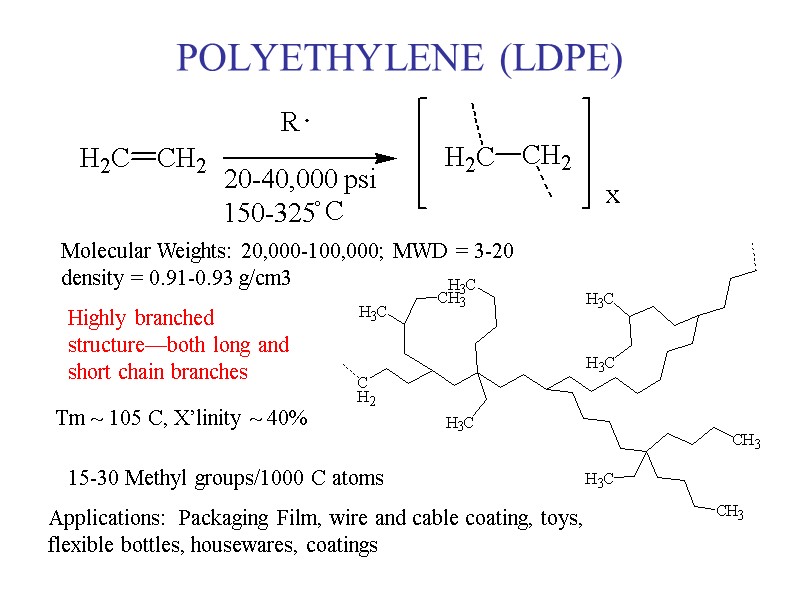

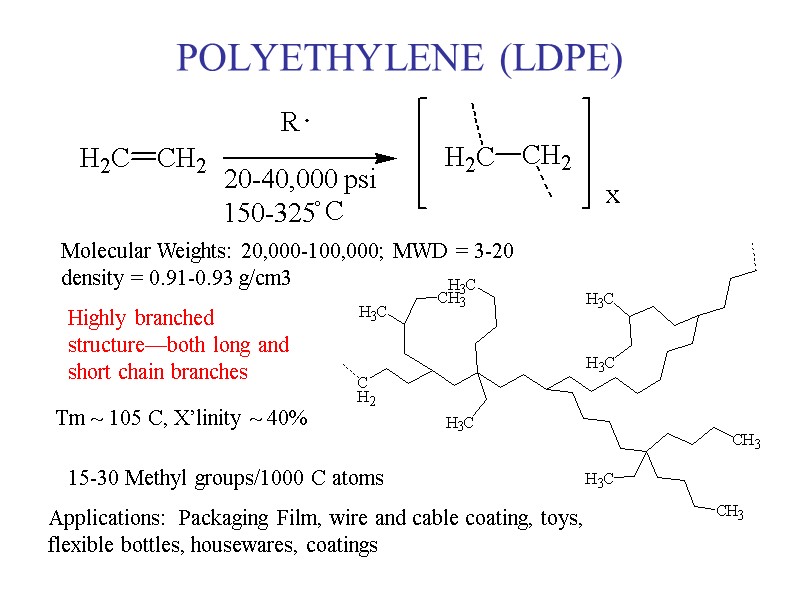

POLYETHYLENE (LDPE) Molecular Weights: 20,000-100,000; MWD = 3-20 density = 0.91-0.93 g/cm3 Highly branched structure—both long and short chain branches 15-30 Methyl groups/1000 C atoms Tm ~ 105 C, X’linity ~ 40% Applications: Packaging Film, wire and cable coating, toys, flexible bottles, housewares, coatings

POLYETHYLENE (LDPE) Molecular Weights: 20,000-100,000; MWD = 3-20 density = 0.91-0.93 g/cm3 Highly branched structure—both long and short chain branches 15-30 Methyl groups/1000 C atoms Tm ~ 105 C, X’linity ~ 40% Applications: Packaging Film, wire and cable coating, toys, flexible bottles, housewares, coatings

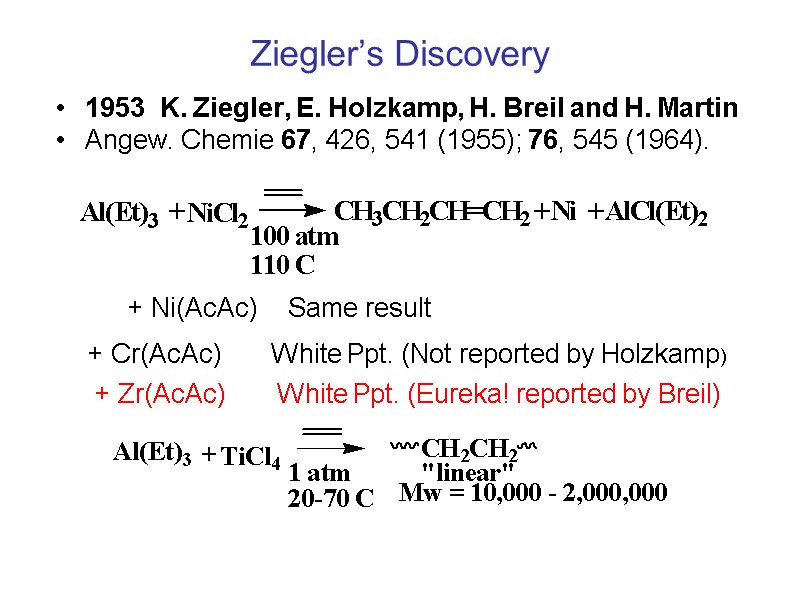

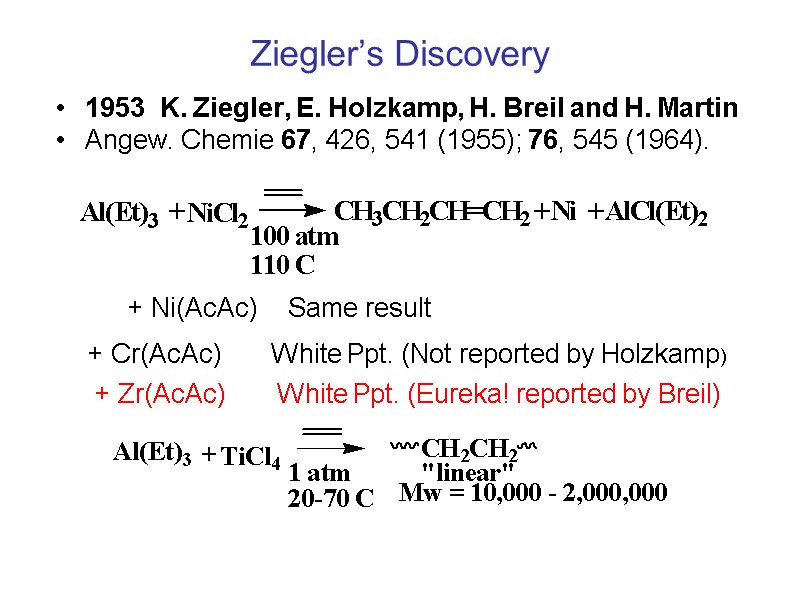

Ziegler’s Discovery 1953 K. Ziegler, E. Holzkamp, H. Breil and H. Martin Angew. Chemie 67, 426, 541 (1955); 76, 545 (1964). + Ni(AcAc) Same result + Cr(AcAc) White Ppt. (Not reported by Holzkamp) + Zr(AcAc) White Ppt. (Eureka! reported by Breil)

Ziegler’s Discovery 1953 K. Ziegler, E. Holzkamp, H. Breil and H. Martin Angew. Chemie 67, 426, 541 (1955); 76, 545 (1964). + Ni(AcAc) Same result + Cr(AcAc) White Ppt. (Not reported by Holzkamp) + Zr(AcAc) White Ppt. (Eureka! reported by Breil)

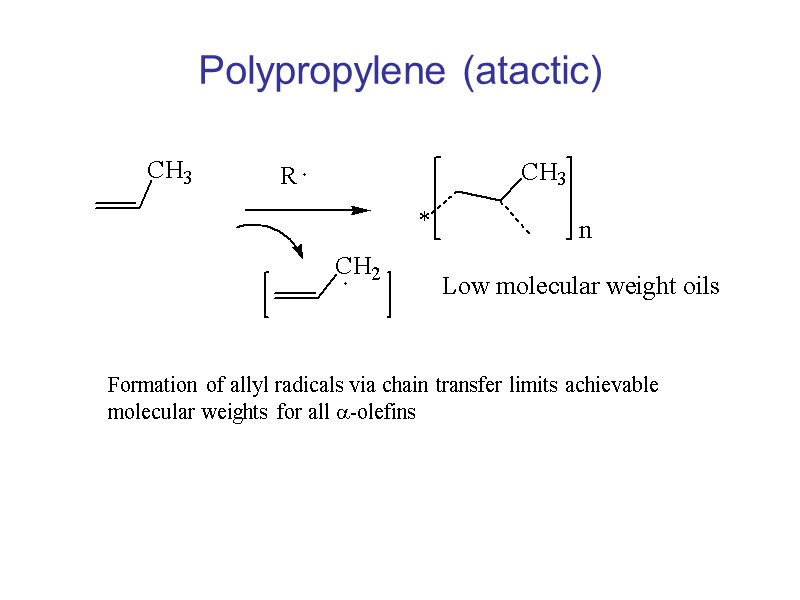

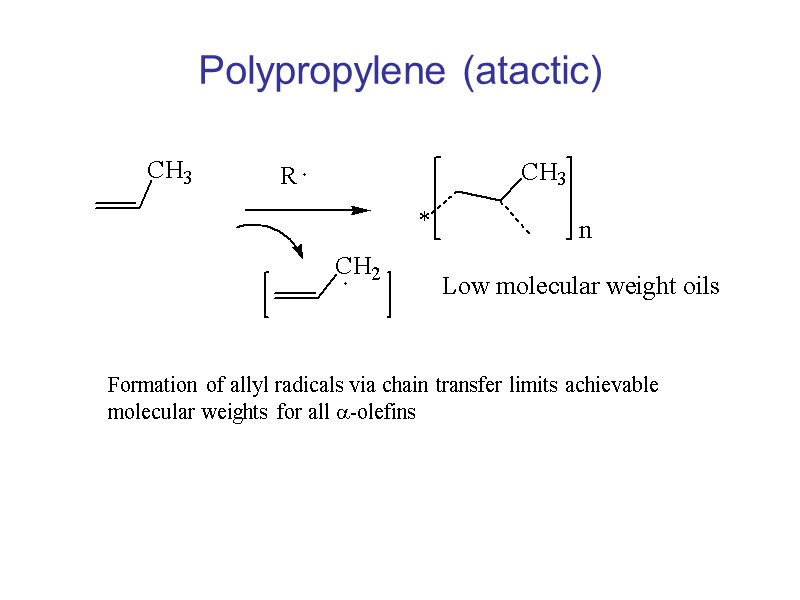

Polypropylene (atactic) Formation of allyl radicals via chain transfer limits achievable molecular weights for all a-olefins

Polypropylene (atactic) Formation of allyl radicals via chain transfer limits achievable molecular weights for all a-olefins

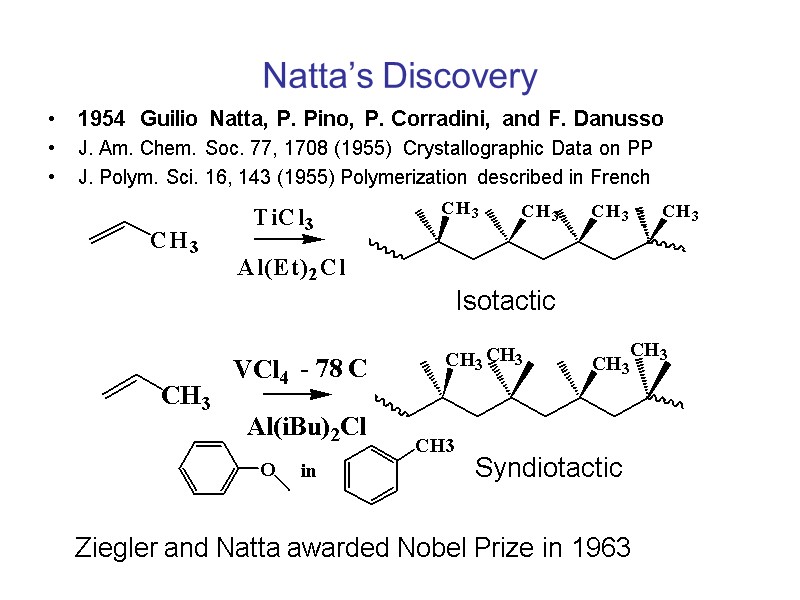

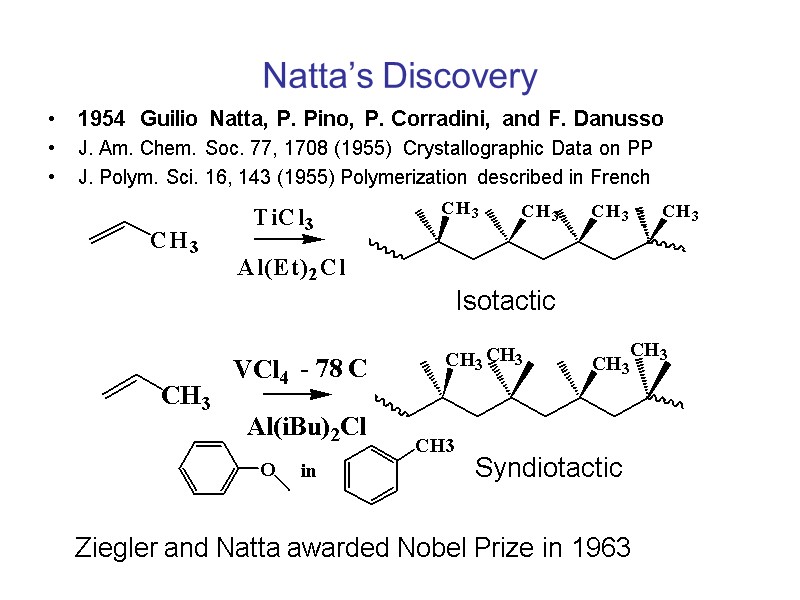

Natta’s Discovery 1954 Guilio Natta, P. Pino, P. Corradini, and F. Danusso J. Am. Chem. Soc. 77, 1708 (1955) Crystallographic Data on PP J. Polym. Sci. 16, 143 (1955) Polymerization described in French Isotactic Syndiotactic Ziegler and Natta awarded Nobel Prize in 1963

Natta’s Discovery 1954 Guilio Natta, P. Pino, P. Corradini, and F. Danusso J. Am. Chem. Soc. 77, 1708 (1955) Crystallographic Data on PP J. Polym. Sci. 16, 143 (1955) Polymerization described in French Isotactic Syndiotactic Ziegler and Natta awarded Nobel Prize in 1963

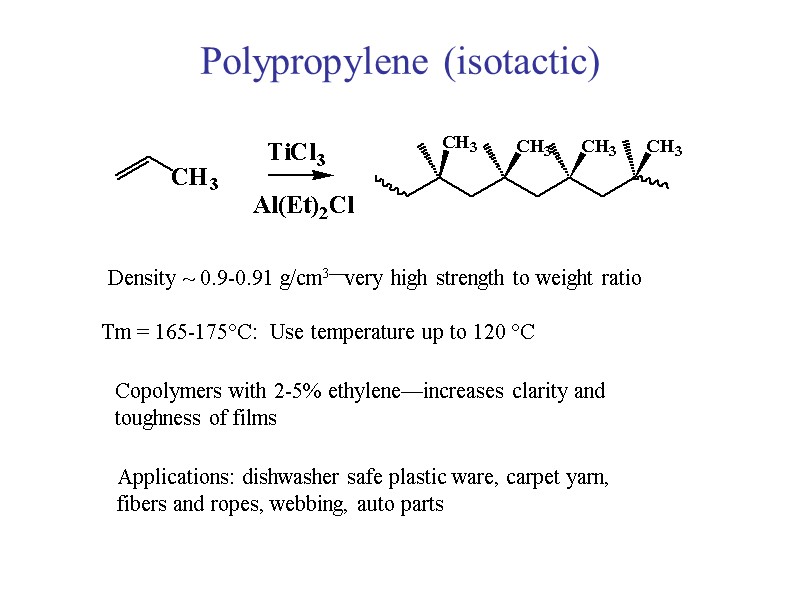

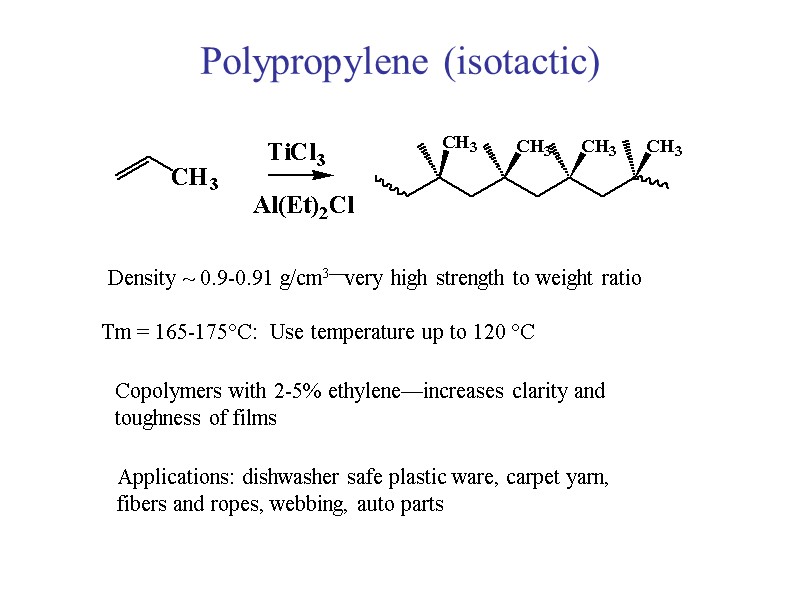

Polypropylene (isotactic) Density ~ 0.9-0.91 g/cm3—very high strength to weight ratio Tm = 165-175C: Use temperature up to 120 C Copolymers with 2-5% ethylene—increases clarity and toughness of films Applications: dishwasher safe plastic ware, carpet yarn, fibers and ropes, webbing, auto parts

Polypropylene (isotactic) Density ~ 0.9-0.91 g/cm3—very high strength to weight ratio Tm = 165-175C: Use temperature up to 120 C Copolymers with 2-5% ethylene—increases clarity and toughness of films Applications: dishwasher safe plastic ware, carpet yarn, fibers and ropes, webbing, auto parts

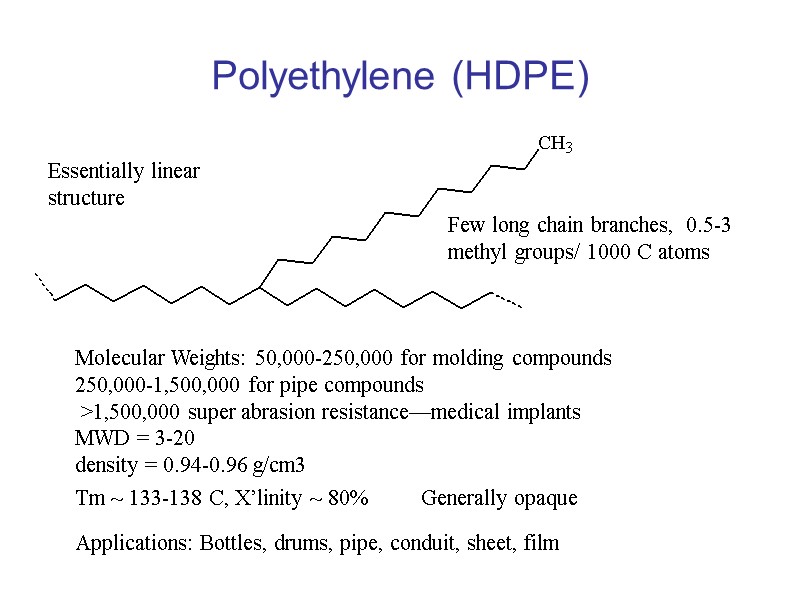

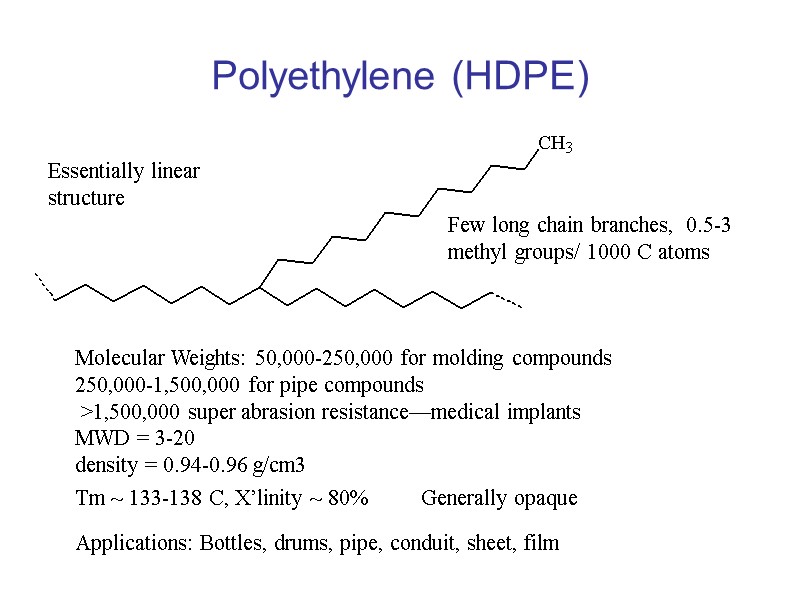

Polyethylene (HDPE) Essentially linear structure Few long chain branches, 0.5-3 methyl groups/ 1000 C atoms Molecular Weights: 50,000-250,000 for molding compounds 250,000-1,500,000 for pipe compounds >1,500,000 super abrasion resistance—medical implants MWD = 3-20 density = 0.94-0.96 g/cm3 Tm ~ 133-138 C, X’linity ~ 80% Applications: Bottles, drums, pipe, conduit, sheet, film Generally opaque

Polyethylene (HDPE) Essentially linear structure Few long chain branches, 0.5-3 methyl groups/ 1000 C atoms Molecular Weights: 50,000-250,000 for molding compounds 250,000-1,500,000 for pipe compounds >1,500,000 super abrasion resistance—medical implants MWD = 3-20 density = 0.94-0.96 g/cm3 Tm ~ 133-138 C, X’linity ~ 80% Applications: Bottles, drums, pipe, conduit, sheet, film Generally opaque

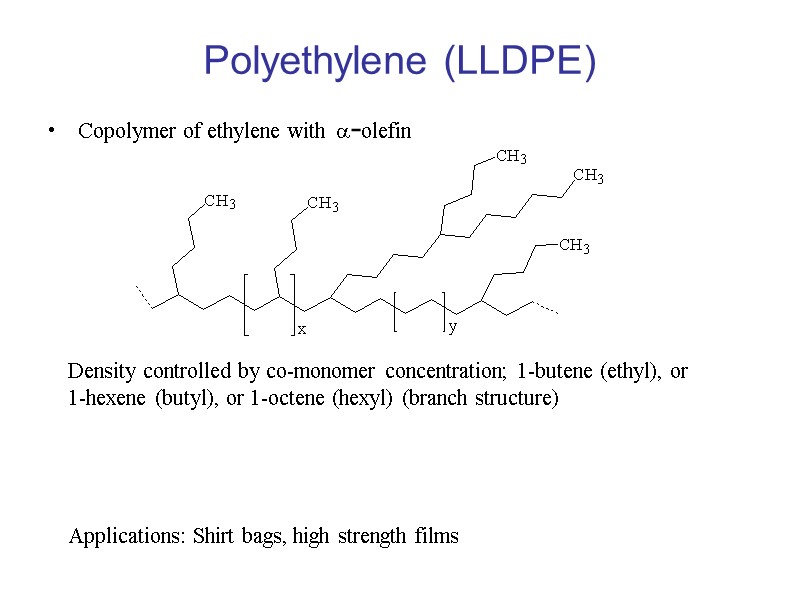

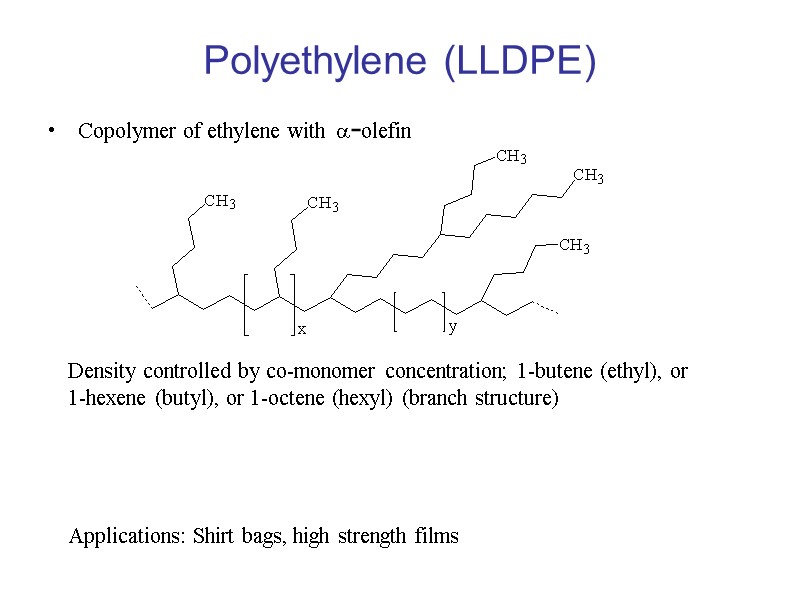

Polyethylene (LLDPE) Copolymer of ethylene with a-olefin Density controlled by co-monomer concentration; 1-butene (ethyl), or 1-hexene (butyl), or 1-octene (hexyl) (branch structure) Applications: Shirt bags, high strength films

Polyethylene (LLDPE) Copolymer of ethylene with a-olefin Density controlled by co-monomer concentration; 1-butene (ethyl), or 1-hexene (butyl), or 1-octene (hexyl) (branch structure) Applications: Shirt bags, high strength films

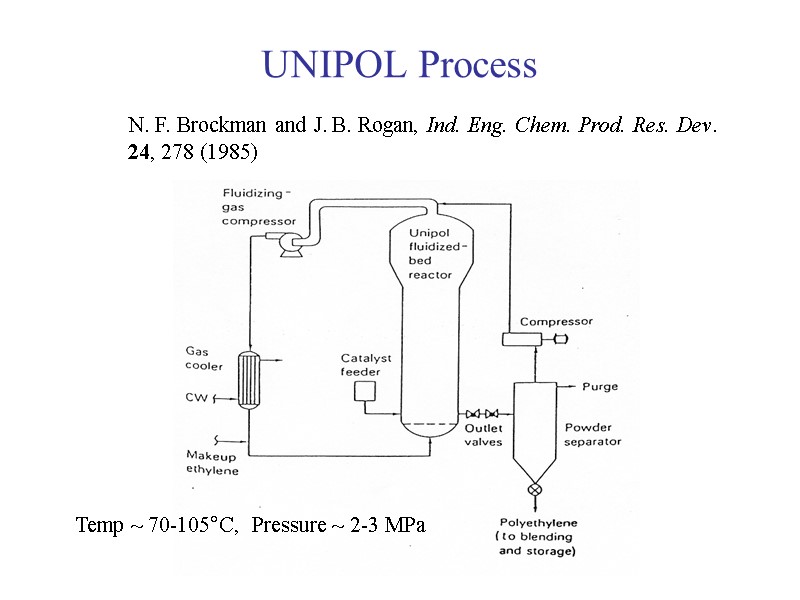

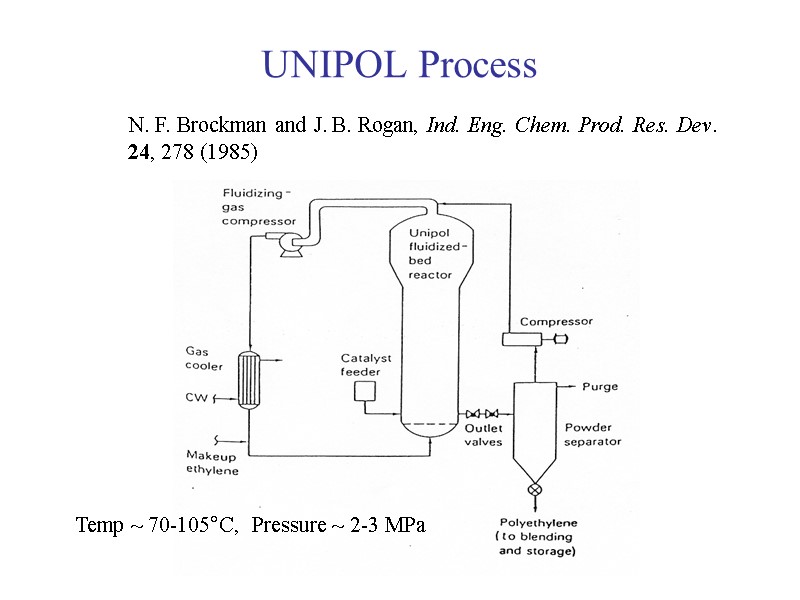

UNIPOL Process N. F. Brockman and J. B. Rogan, Ind. Eng. Chem. Prod. Res. Dev. 24, 278 (1985) Temp ~ 70-105°C, Pressure ~ 2-3 MPa

UNIPOL Process N. F. Brockman and J. B. Rogan, Ind. Eng. Chem. Prod. Res. Dev. 24, 278 (1985) Temp ~ 70-105°C, Pressure ~ 2-3 MPa

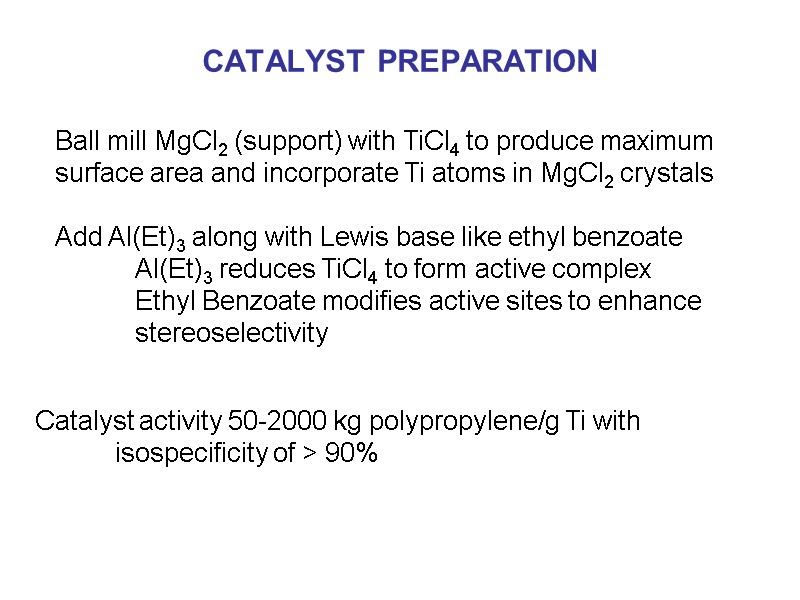

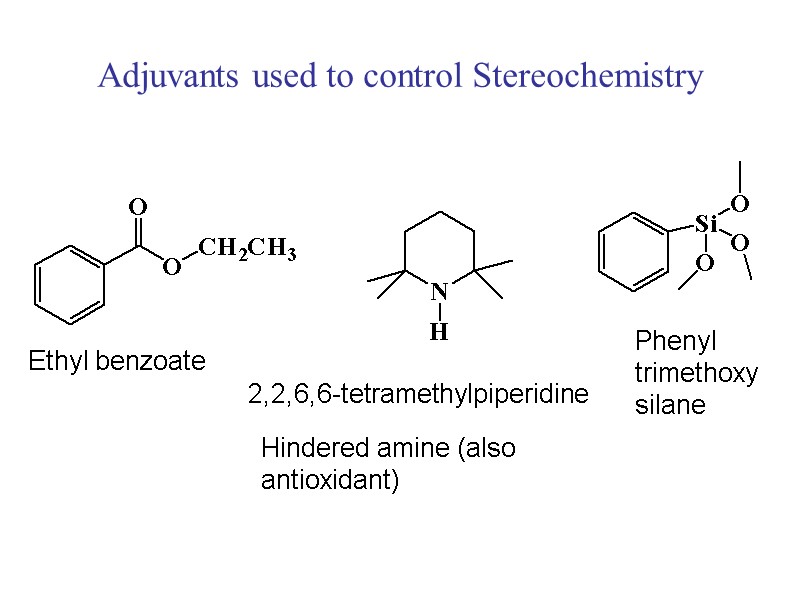

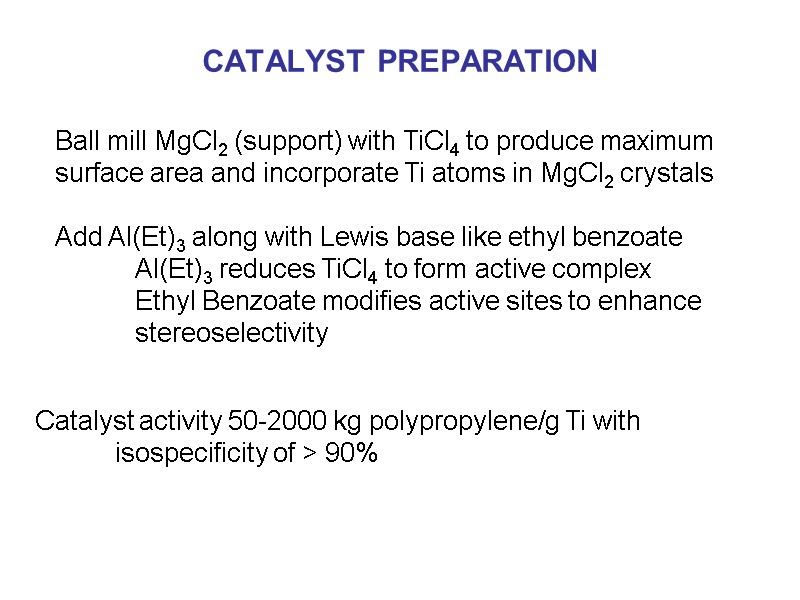

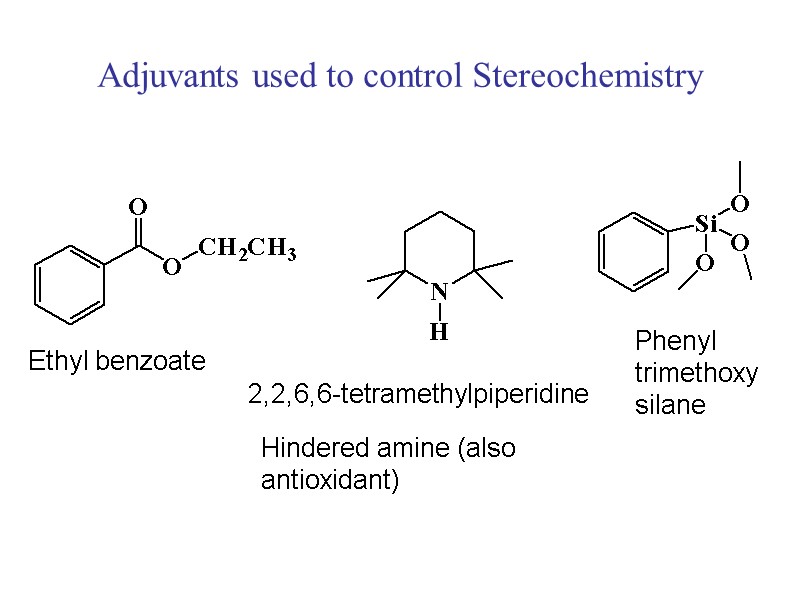

CATALYST PREPARATION Ball mill MgCl2 (support) with TiCl4 to produce maximum surface area and incorporate Ti atoms in MgCl2 crystals Add Al(Et)3 along with Lewis base like ethyl benzoate Al(Et)3 reduces TiCl4 to form active complex Ethyl Benzoate modifies active sites to enhance stereoselectivity Catalyst activity 50-2000 kg polypropylene/g Ti with isospecificity of > 90%

CATALYST PREPARATION Ball mill MgCl2 (support) with TiCl4 to produce maximum surface area and incorporate Ti atoms in MgCl2 crystals Add Al(Et)3 along with Lewis base like ethyl benzoate Al(Et)3 reduces TiCl4 to form active complex Ethyl Benzoate modifies active sites to enhance stereoselectivity Catalyst activity 50-2000 kg polypropylene/g Ti with isospecificity of > 90%

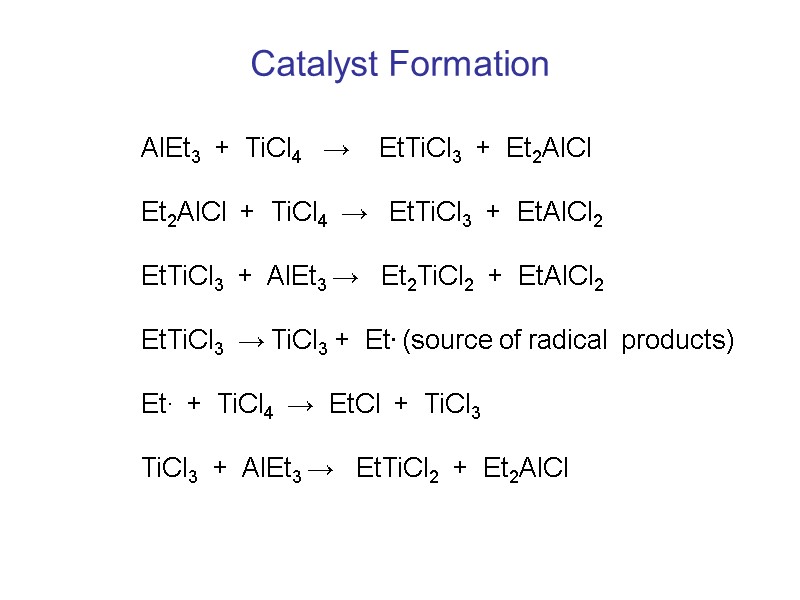

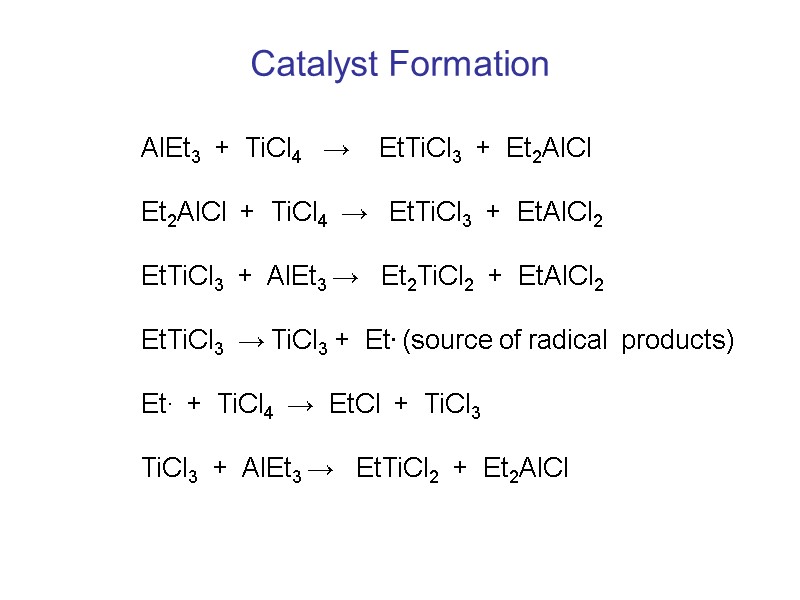

Catalyst Formation AlEt3 + TiCl4 → EtTiCl3 + Et2AlCl Et2AlCl + TiCl4 → EtTiCl3 + EtAlCl2 EtTiCl3 + AlEt3 → Et2TiCl2 + EtAlCl2 EtTiCl3 → TiCl3 + Et. (source of radical products) Et. + TiCl4 → EtCl + TiCl3 TiCl3 + AlEt3 → EtTiCl2 + Et2AlCl

Catalyst Formation AlEt3 + TiCl4 → EtTiCl3 + Et2AlCl Et2AlCl + TiCl4 → EtTiCl3 + EtAlCl2 EtTiCl3 + AlEt3 → Et2TiCl2 + EtAlCl2 EtTiCl3 → TiCl3 + Et. (source of radical products) Et. + TiCl4 → EtCl + TiCl3 TiCl3 + AlEt3 → EtTiCl2 + Et2AlCl

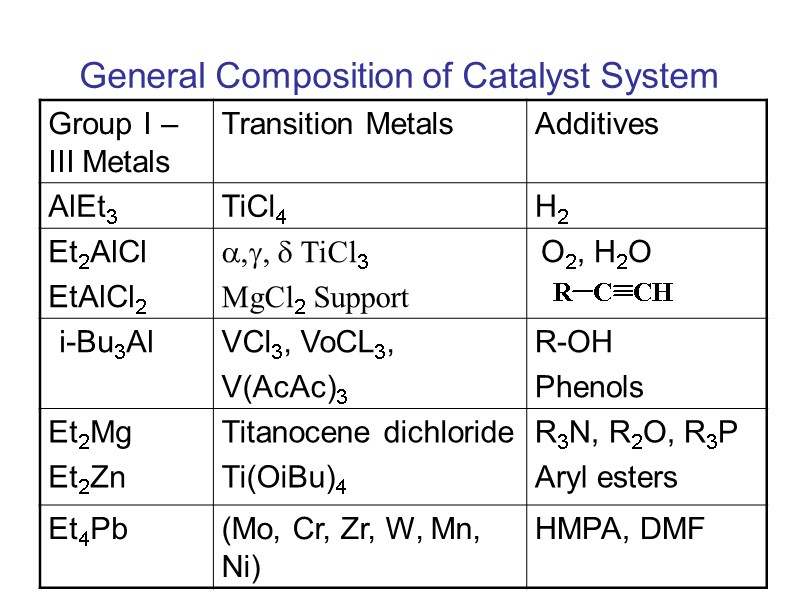

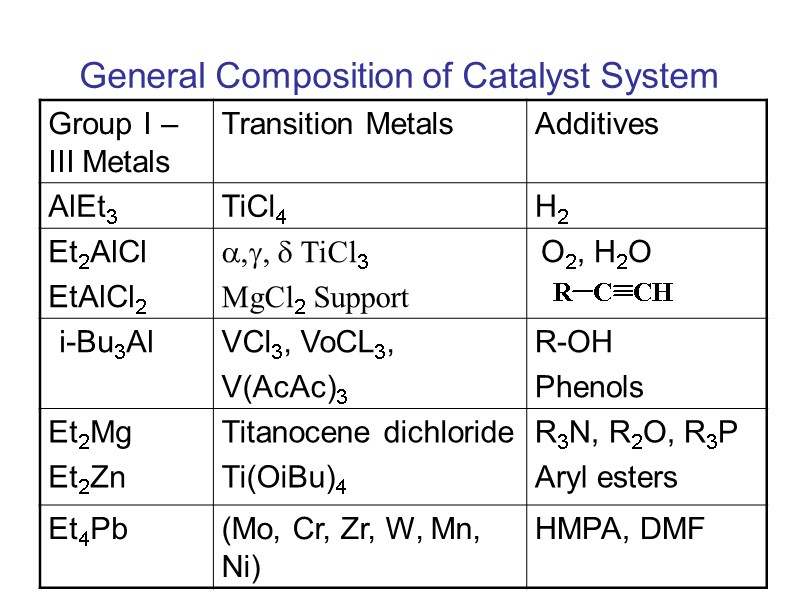

General Composition of Catalyst System

General Composition of Catalyst System

Adjuvants used to control Stereochemistry Ethyl benzoate 2,2,6,6-tetramethylpiperidine Hindered amine (also antioxidant) Phenyl trimethoxy silane

Adjuvants used to control Stereochemistry Ethyl benzoate 2,2,6,6-tetramethylpiperidine Hindered amine (also antioxidant) Phenyl trimethoxy silane

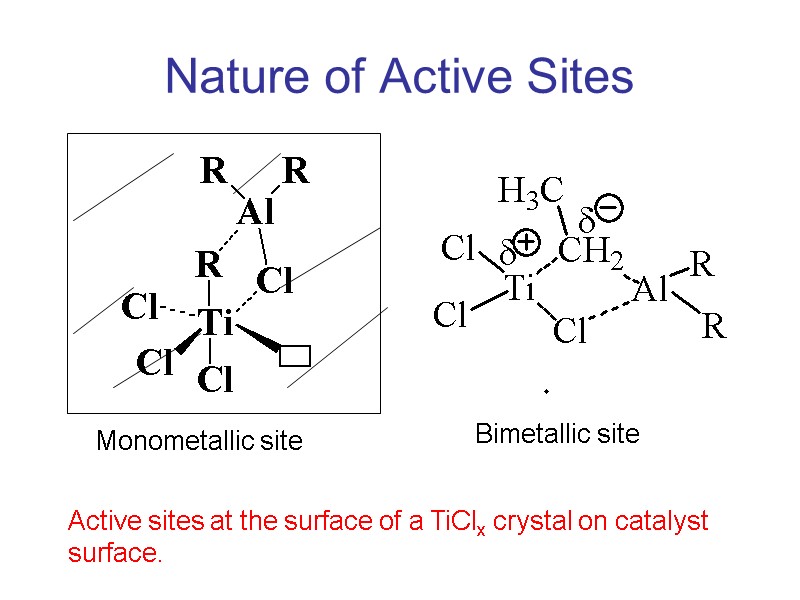

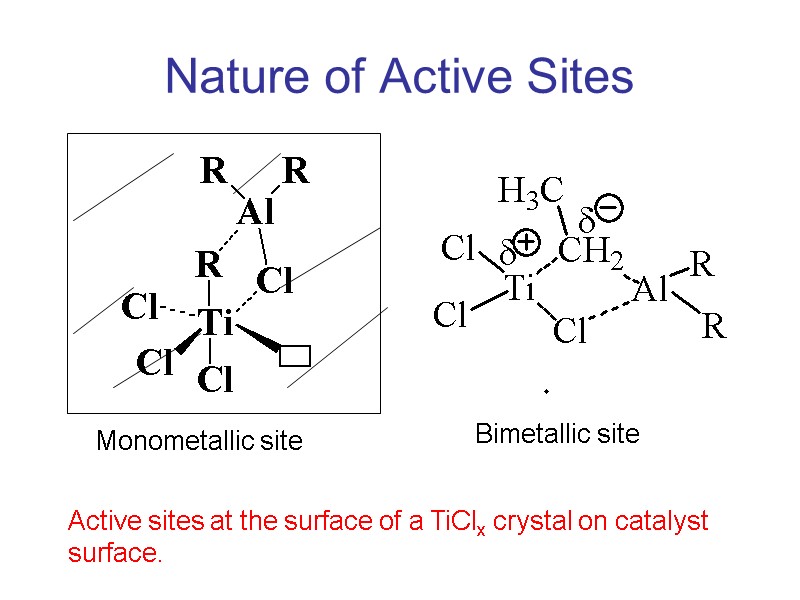

Nature of Active Sites Monometallic site Bimetallic site Active sites at the surface of a TiClx crystal on catalyst surface.

Nature of Active Sites Monometallic site Bimetallic site Active sites at the surface of a TiClx crystal on catalyst surface.

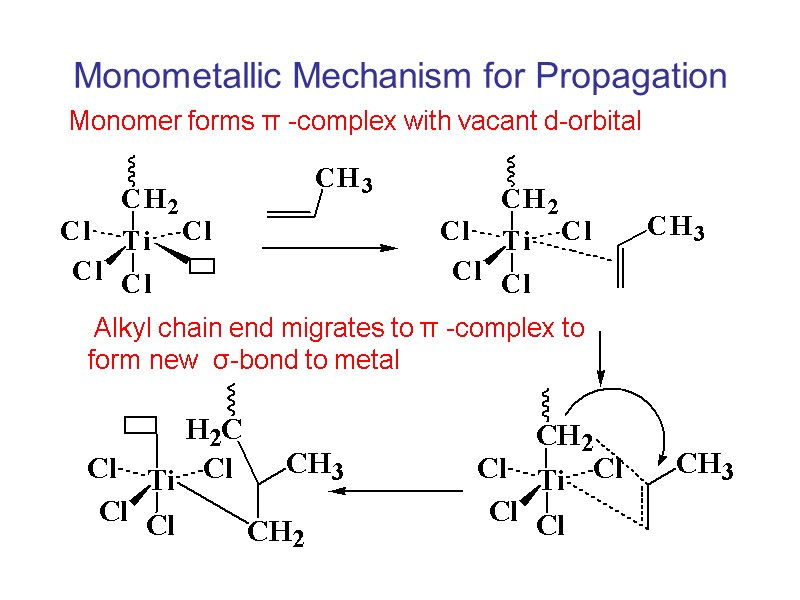

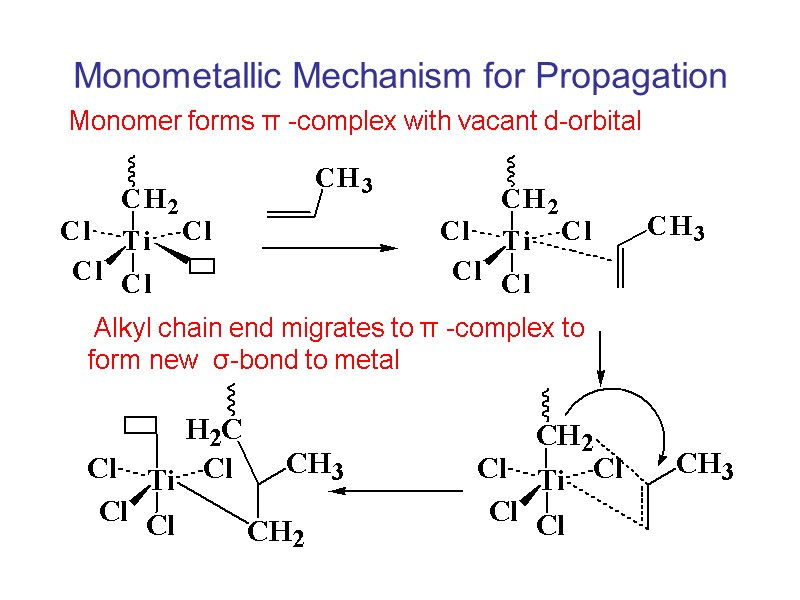

Monometallic Mechanism for Propagation Monomer forms π -complex with vacant d-orbital Alkyl chain end migrates to π -complex to form new σ-bond to metal

Monometallic Mechanism for Propagation Monomer forms π -complex with vacant d-orbital Alkyl chain end migrates to π -complex to form new σ-bond to metal

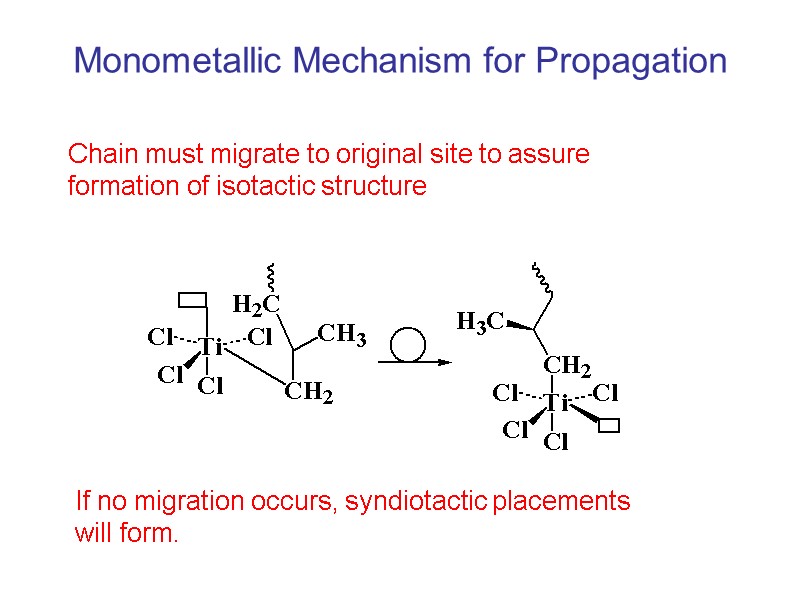

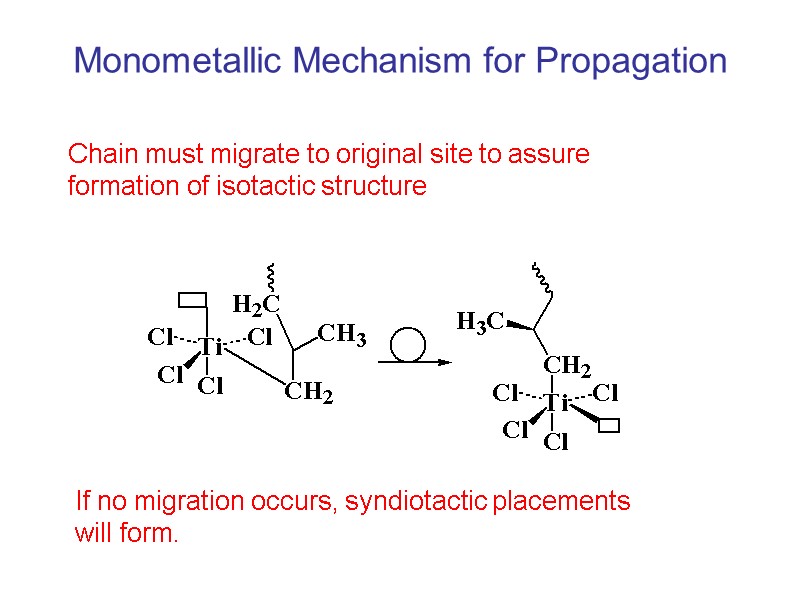

Monometallic Mechanism for Propagation Chain must migrate to original site to assure formation of isotactic structure If no migration occurs, syndiotactic placements will form.

Monometallic Mechanism for Propagation Chain must migrate to original site to assure formation of isotactic structure If no migration occurs, syndiotactic placements will form.

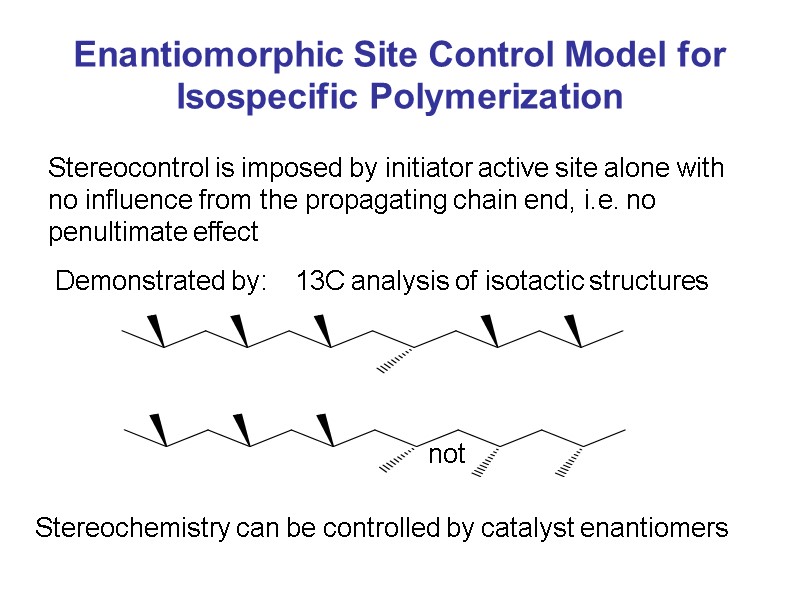

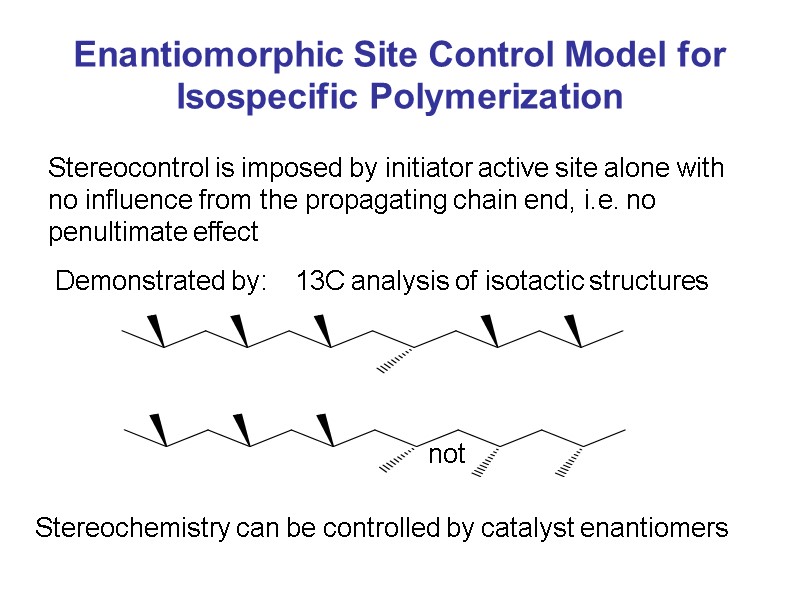

Enantiomorphic Site Control Model for Isospecific Polymerization Stereocontrol is imposed by initiator active site alone with no influence from the propagating chain end, i.e. no penultimate effect Demonstrated by: 13C analysis of isotactic structures not Stereochemistry can be controlled by catalyst enantiomers

Enantiomorphic Site Control Model for Isospecific Polymerization Stereocontrol is imposed by initiator active site alone with no influence from the propagating chain end, i.e. no penultimate effect Demonstrated by: 13C analysis of isotactic structures not Stereochemistry can be controlled by catalyst enantiomers

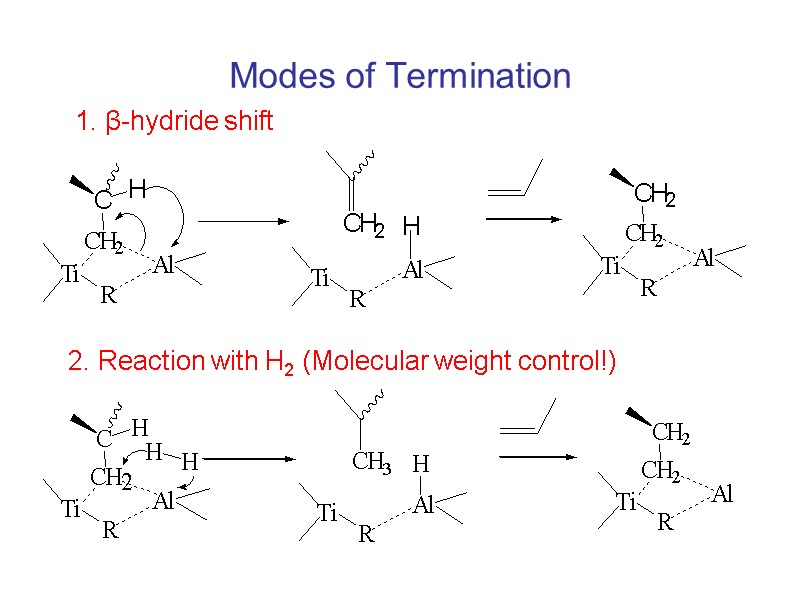

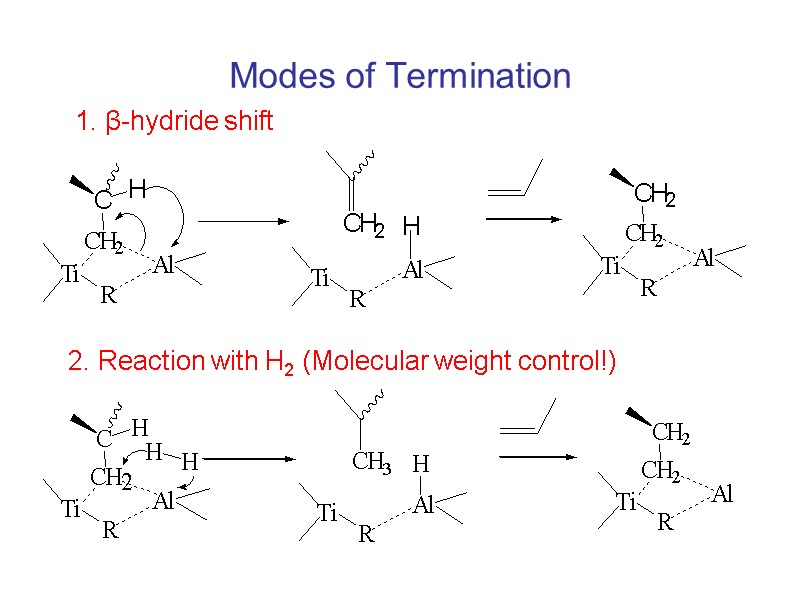

Modes of Termination 1. β-hydride shift 2. Reaction with H2 (Molecular weight control!)

Modes of Termination 1. β-hydride shift 2. Reaction with H2 (Molecular weight control!)

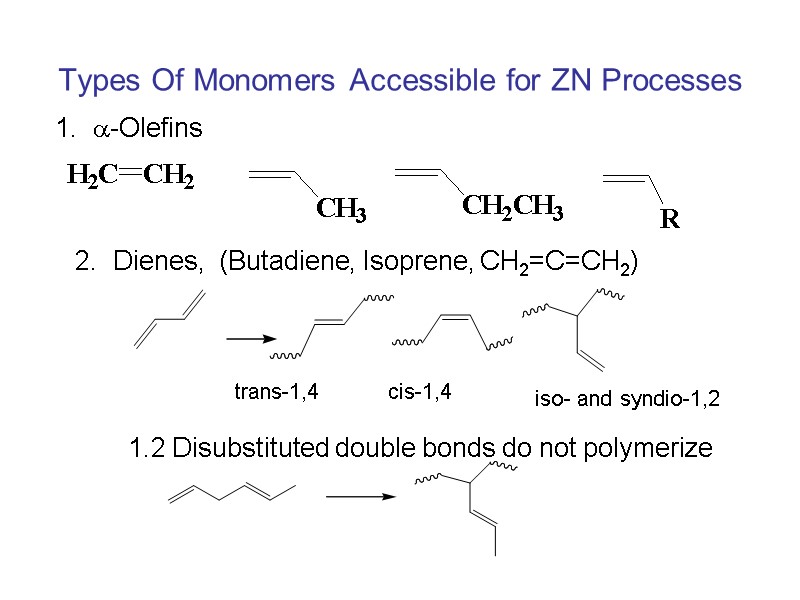

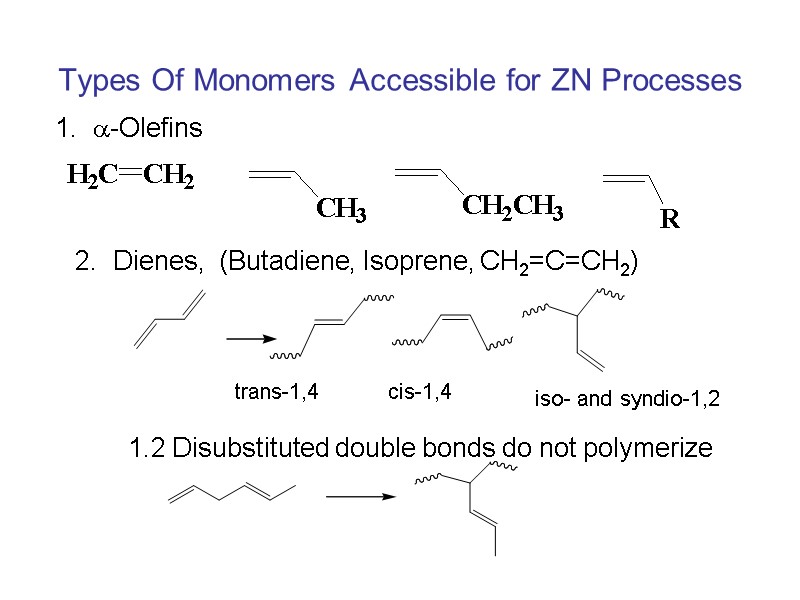

Types Of Monomers Accessible for ZN Processes 1. -Olefins 2. Dienes, (Butadiene, Isoprene, CH2=C=CH2) 1.2 Disubstituted double bonds do not polymerize trans-1,4 cis-1,4 iso- and syndio-1,2

Types Of Monomers Accessible for ZN Processes 1. -Olefins 2. Dienes, (Butadiene, Isoprene, CH2=C=CH2) 1.2 Disubstituted double bonds do not polymerize trans-1,4 cis-1,4 iso- and syndio-1,2

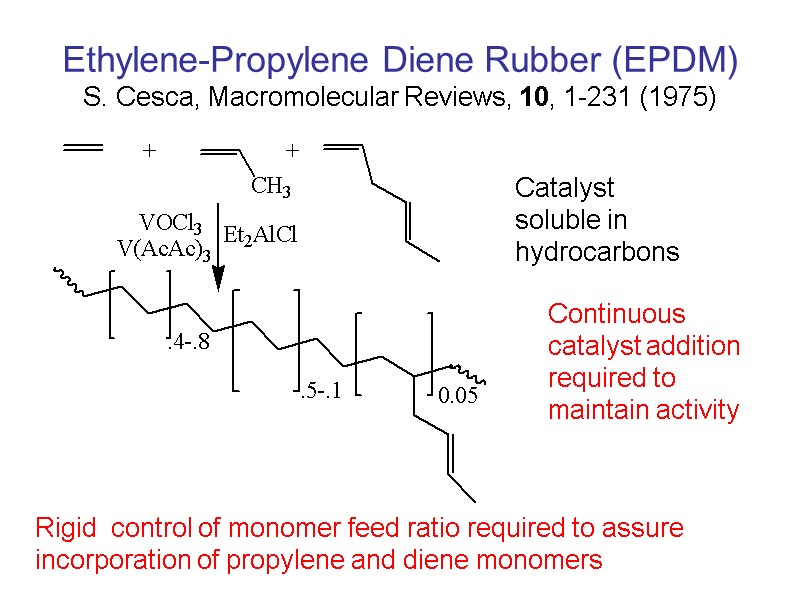

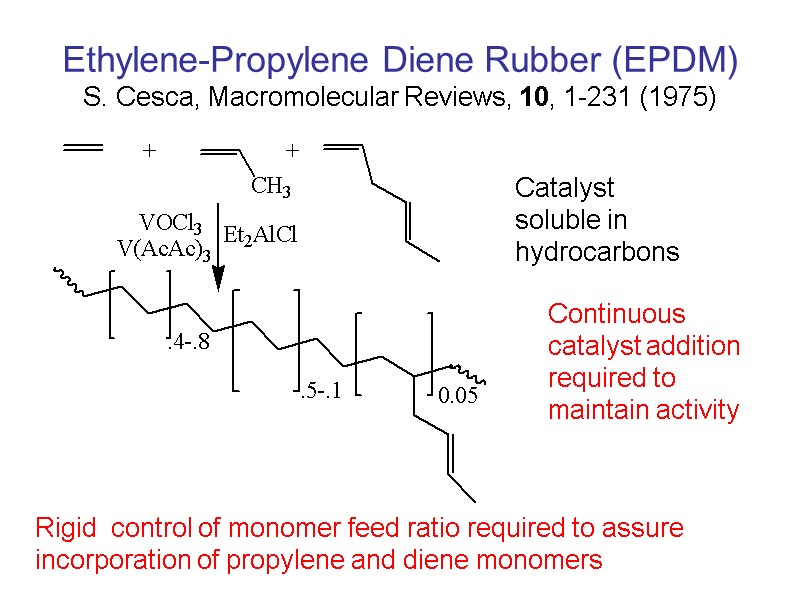

Ethylene-Propylene Diene Rubber (EPDM) S. Cesca, Macromolecular Reviews, 10, 1-231 (1975) Catalyst soluble in hydrocarbons Continuous catalyst addition required to maintain activity Rigid control of monomer feed ratio required to assure incorporation of propylene and diene monomers

Ethylene-Propylene Diene Rubber (EPDM) S. Cesca, Macromolecular Reviews, 10, 1-231 (1975) Catalyst soluble in hydrocarbons Continuous catalyst addition required to maintain activity Rigid control of monomer feed ratio required to assure incorporation of propylene and diene monomers

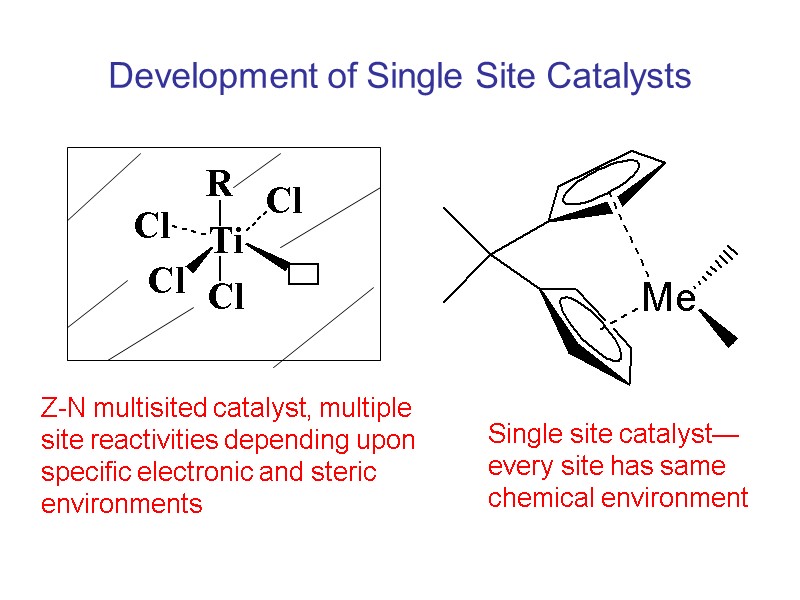

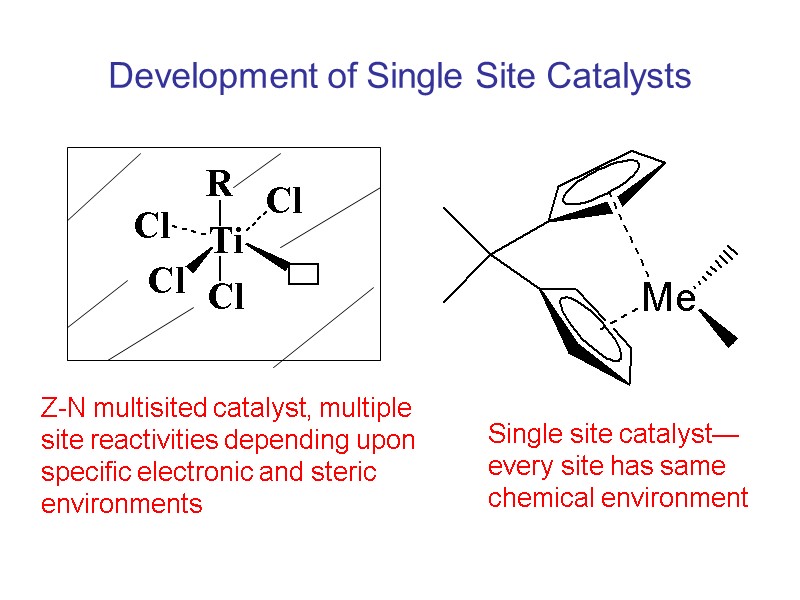

Development of Single Site Catalysts Z-N multisited catalyst, multiple site reactivities depending upon specific electronic and steric environments Single site catalyst—every site has same chemical environment

Development of Single Site Catalysts Z-N multisited catalyst, multiple site reactivities depending upon specific electronic and steric environments Single site catalyst—every site has same chemical environment

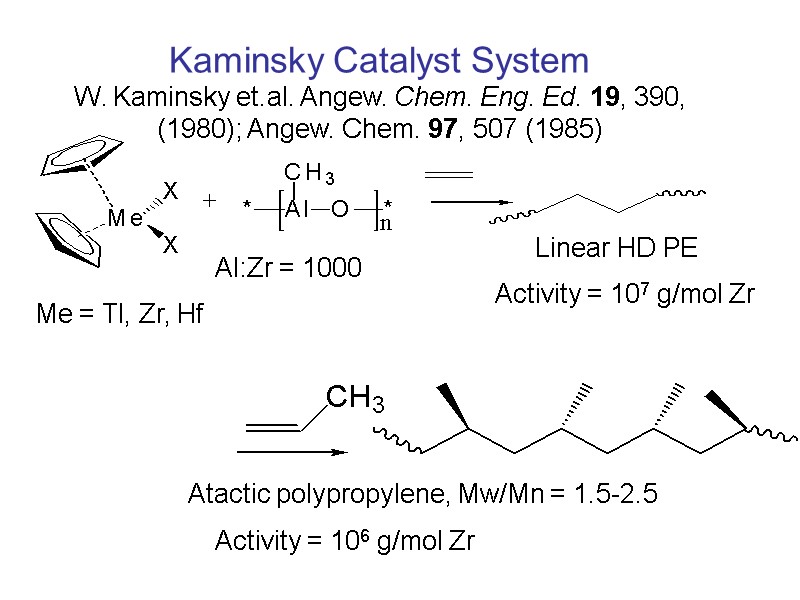

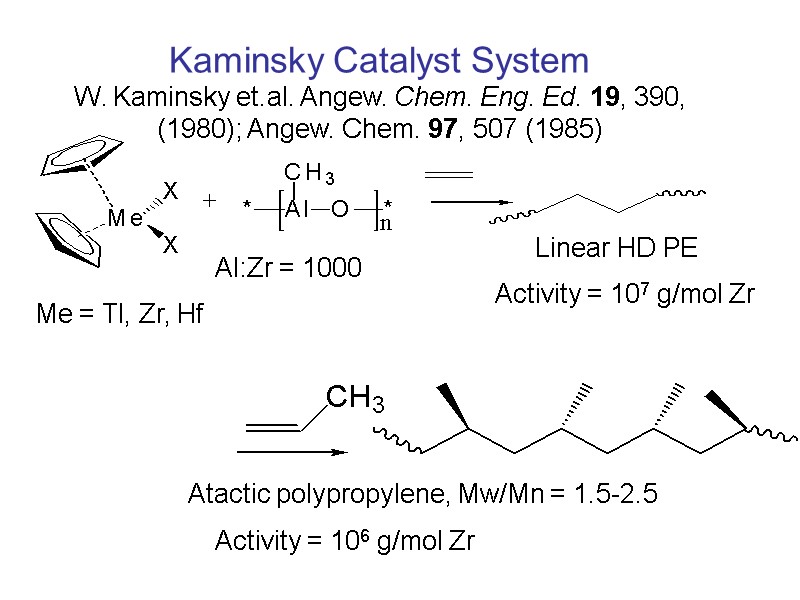

Al:Zr = 1000 Me = Tl, Zr, Hf Linear HD PE Activity = 107 g/mol Zr Atactic polypropylene, Mw/Mn = 1.5-2.5 Activity = 106 g/mol Zr Kaminsky Catalyst System W. Kaminsky et.al. Angew. Chem. Eng. Ed. 19, 390, (1980); Angew. Chem. 97, 507 (1985)

Al:Zr = 1000 Me = Tl, Zr, Hf Linear HD PE Activity = 107 g/mol Zr Atactic polypropylene, Mw/Mn = 1.5-2.5 Activity = 106 g/mol Zr Kaminsky Catalyst System W. Kaminsky et.al. Angew. Chem. Eng. Ed. 19, 390, (1980); Angew. Chem. 97, 507 (1985)

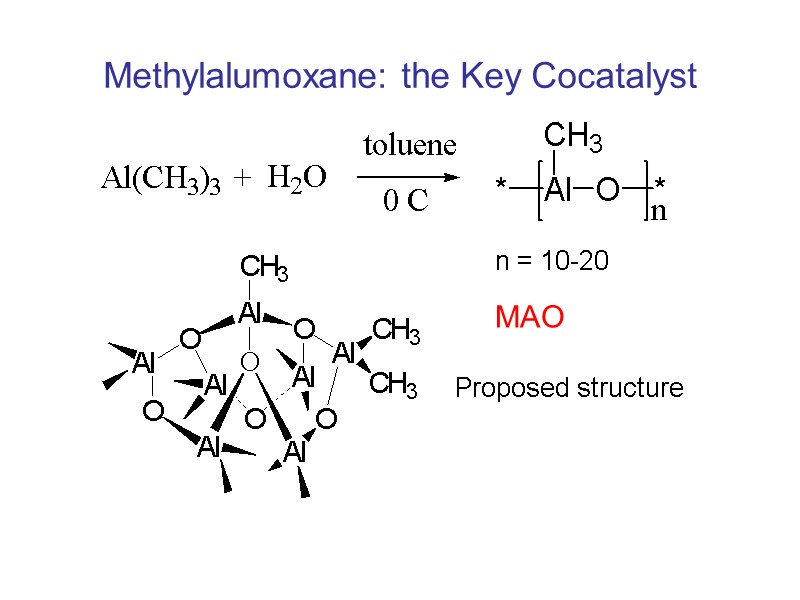

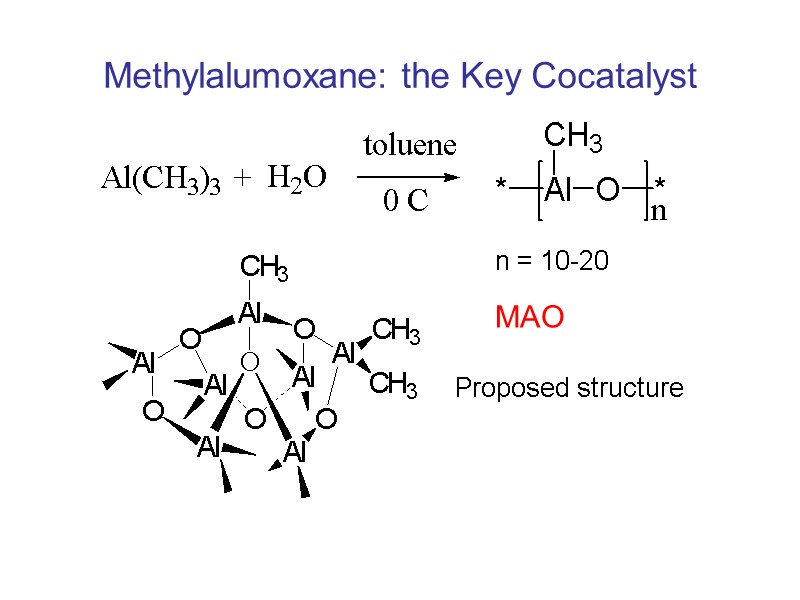

Methylalumoxane: the Key Cocatalyst n = 10-20 Proposed structure MAO

Methylalumoxane: the Key Cocatalyst n = 10-20 Proposed structure MAO

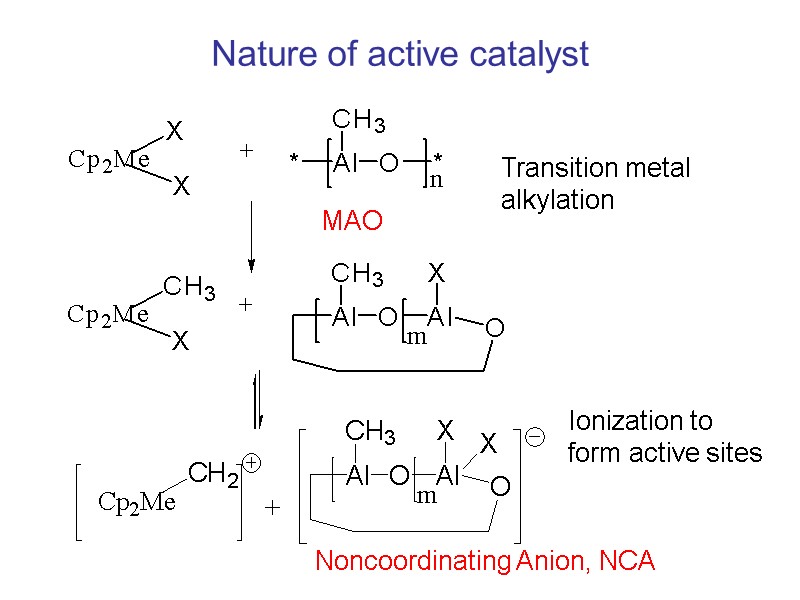

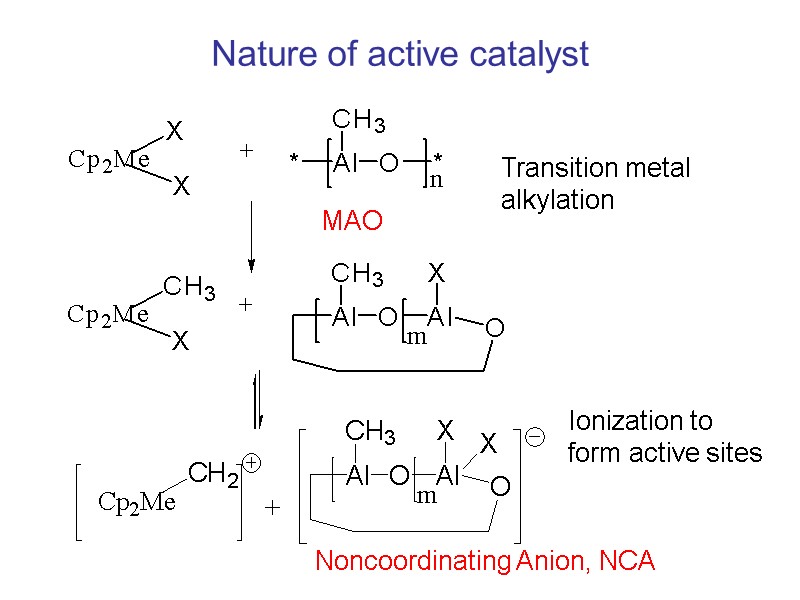

Nature of active catalyst Transition metal alkylation Ionization to form active sites MAO Noncoordinating Anion, NCA

Nature of active catalyst Transition metal alkylation Ionization to form active sites MAO Noncoordinating Anion, NCA

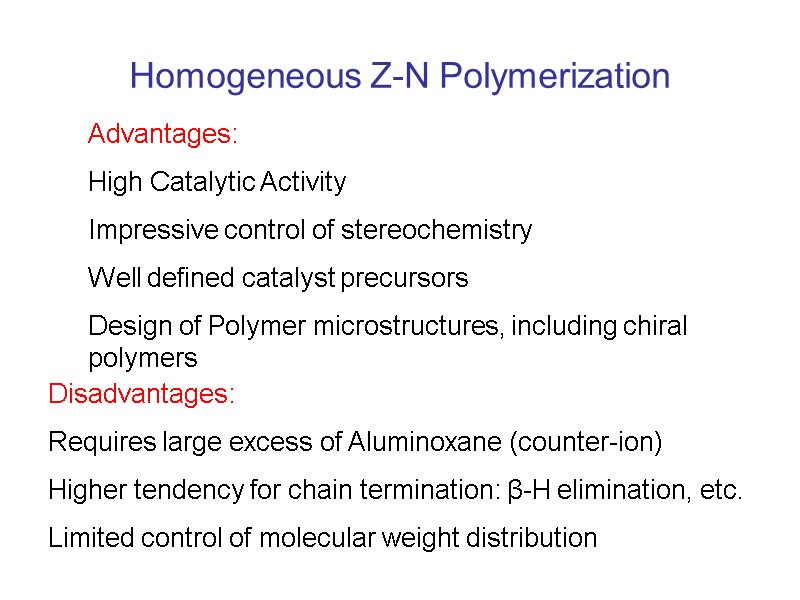

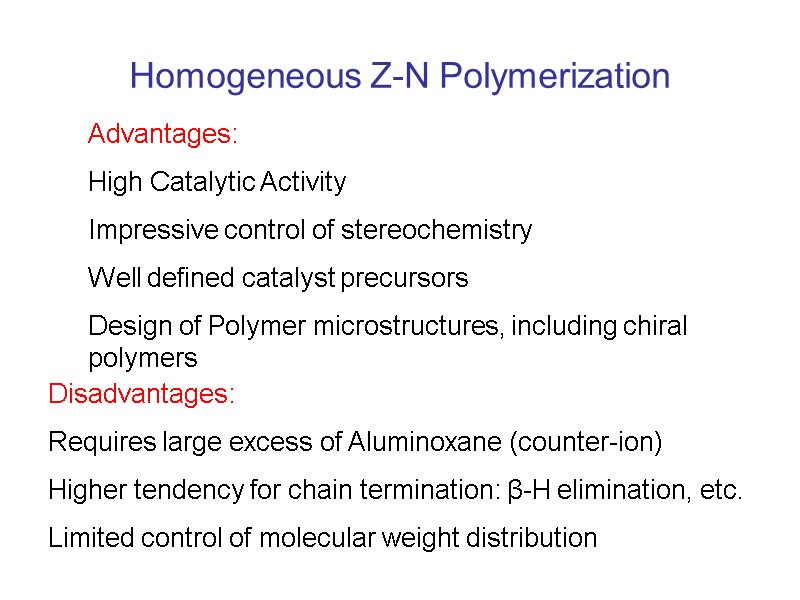

Homogeneous Z-N Polymerization Advantages: High Catalytic Activity Impressive control of stereochemistry Well defined catalyst precursors Design of Polymer microstructures, including chiral polymers Disadvantages: Requires large excess of Aluminoxane (counter-ion) Higher tendency for chain termination: β-H elimination, etc. Limited control of molecular weight distribution

Homogeneous Z-N Polymerization Advantages: High Catalytic Activity Impressive control of stereochemistry Well defined catalyst precursors Design of Polymer microstructures, including chiral polymers Disadvantages: Requires large excess of Aluminoxane (counter-ion) Higher tendency for chain termination: β-H elimination, etc. Limited control of molecular weight distribution

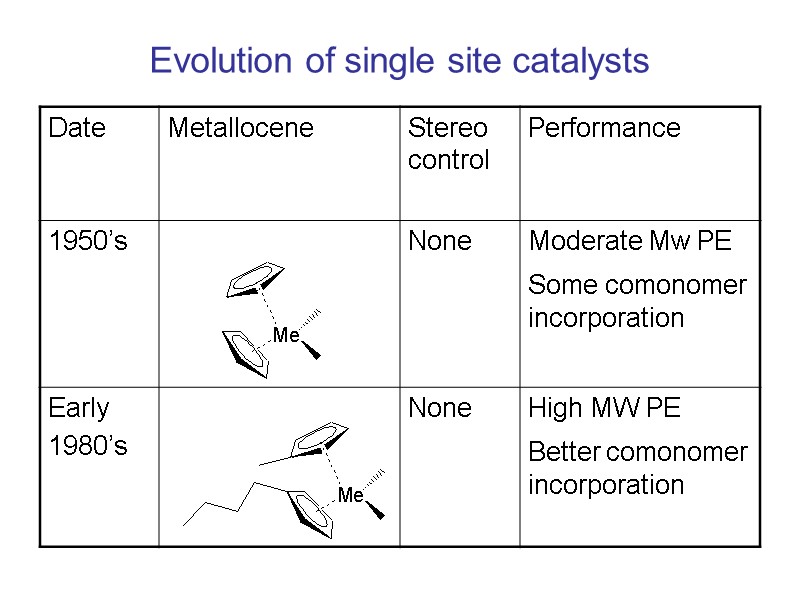

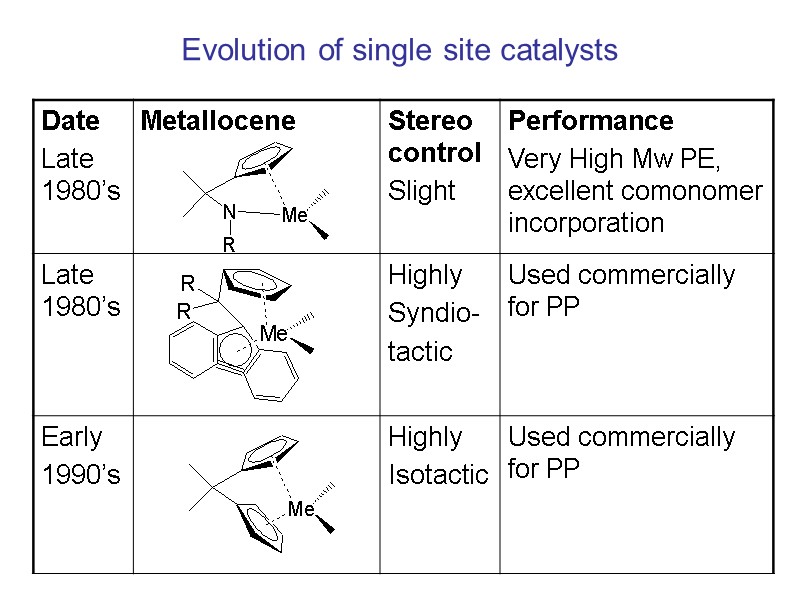

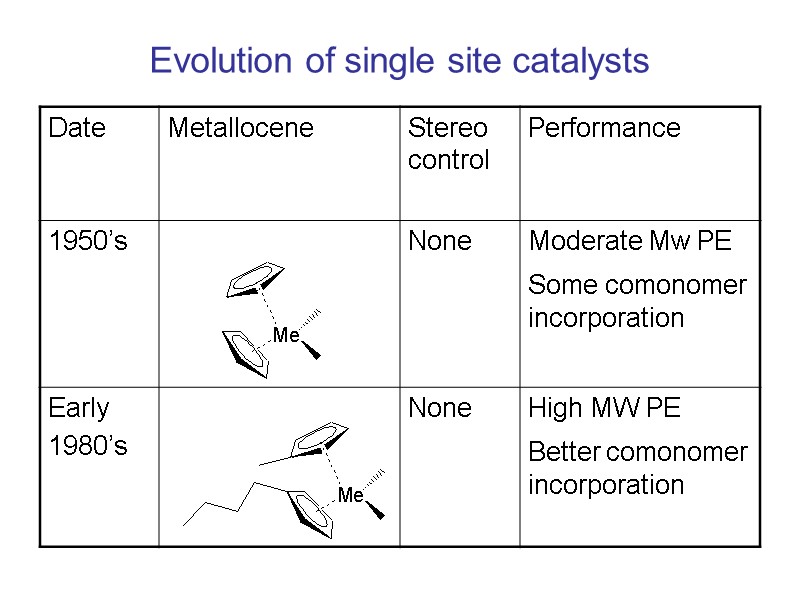

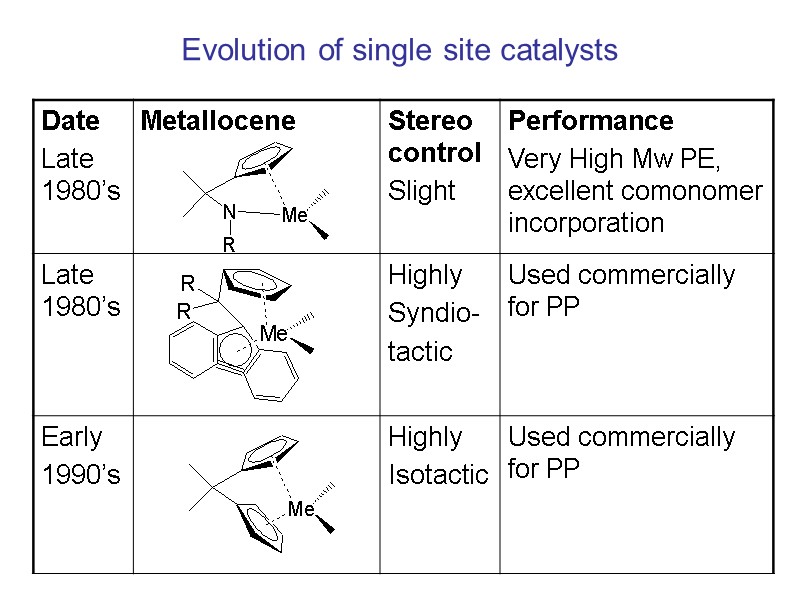

Evolution of single site catalysts

Evolution of single site catalysts

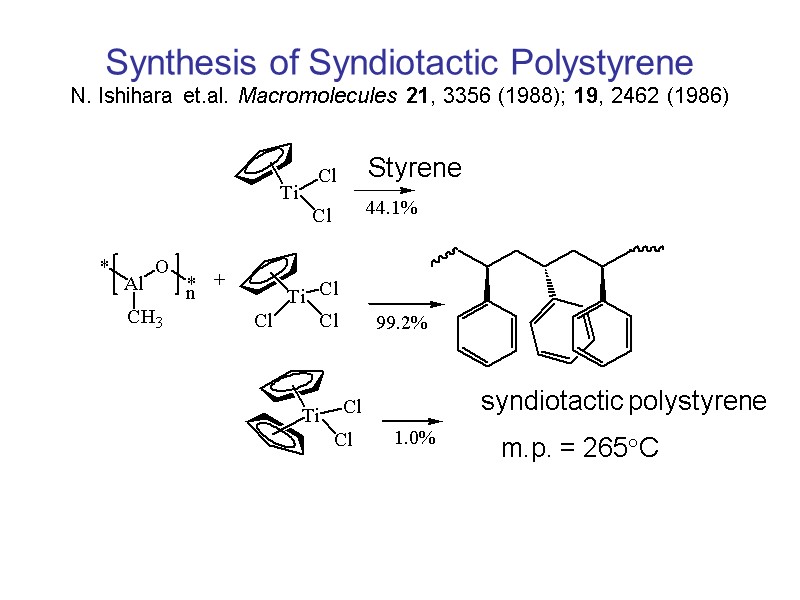

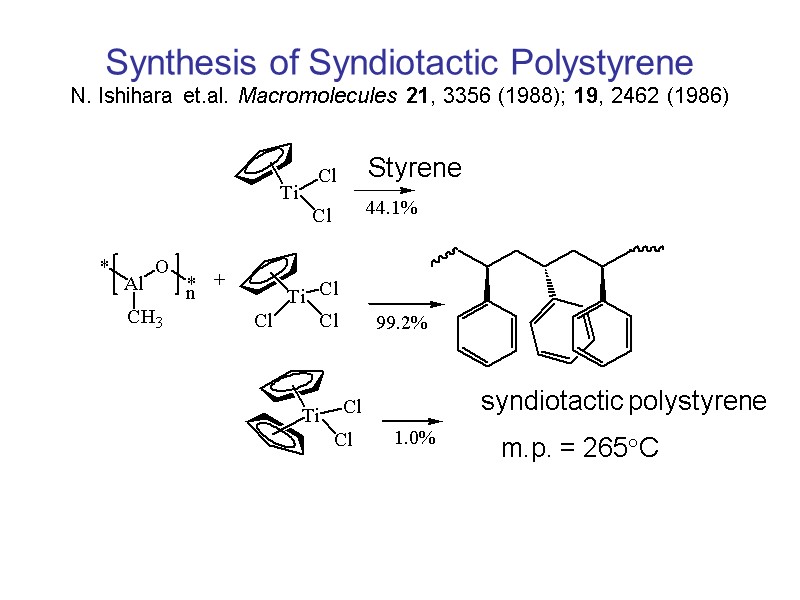

Synthesis of Syndiotactic Polystyrene N. Ishihara et.al. Macromolecules 21, 3356 (1988); 19, 2462 (1986) syndiotactic polystyrene m.p. = 265C Styrene

Synthesis of Syndiotactic Polystyrene N. Ishihara et.al. Macromolecules 21, 3356 (1988); 19, 2462 (1986) syndiotactic polystyrene m.p. = 265C Styrene

Evolution of single site catalysts

Evolution of single site catalysts

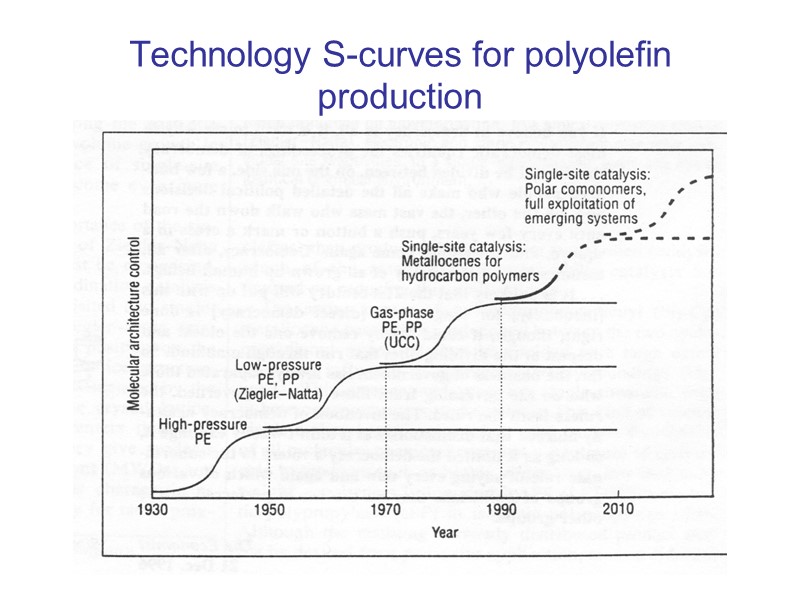

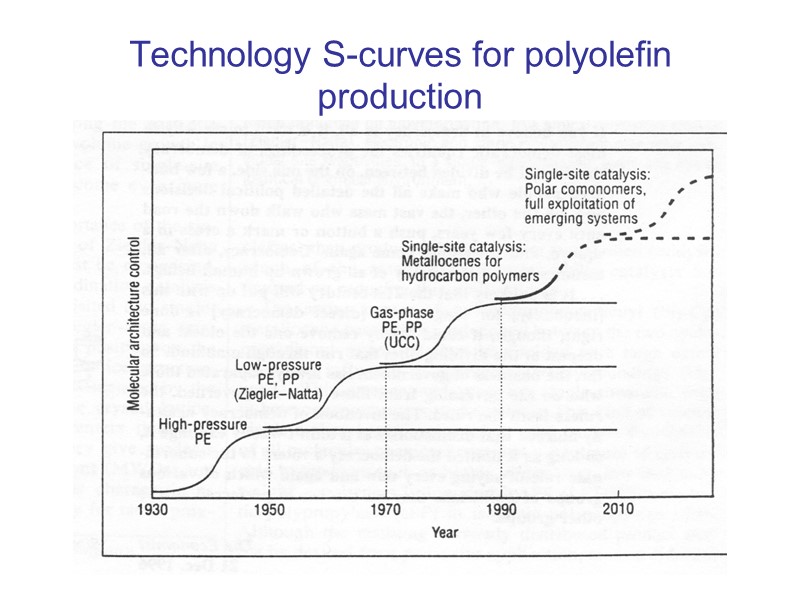

Technology S-curves for polyolefin production

Technology S-curves for polyolefin production